A High-Frequency Soft Switched Inverter with a Low-Loss and Low

Oct 24, 2024 · A High-Frequency Soft Switched Inverter with a Low-Loss and Low Device Stress Auxiliary ZVT Circuit for High-Voltage Applications Published in: 2024 IEEE Energy

A New Grid-Connected DC/AC Inverter With Soft Switching and Low Current

Aug 3, 2018 · This paper presents a new dc/ac inverter for low-power applications (i.e., high-voltage, low-current applications), which offers soft switching of the power semiconductors and

High Voltage Inverters: Understanding Its Benefits and

Jan 23, 2025 · A high-voltage inverter is designed to convert low-voltage DC power to high-voltage AC power efficiently. These inverters are commonly used in applications that require

Inverter Basics: Classification and Applications

Jan 3, 2021 · Inverter Basics: Resonant Inverters This is the class of inverters in which output voltage or current is passed though zero to minimize switching

Lecture 19: Inverters, Part 3

Feb 24, 2025 · Lecture 19 - Inverters 3 Prof. David Perreault We have seen that we can use harmonic elimination to eliminate low-frequency harmonic content at the expense of high

Understanding Inverter Voltage: Definition,

Dec 16, 2024 · The voltage of an inverter itself is divided into several types, the first is a low-voltage inverter, a medium-voltage inverter, and a high-voltage

High Voltage Inverter: Unlocking the Potential of High

Aug 17, 2025 · Generally, a high voltage inverter is a type of inverter voltage that works by converting direct current (DC) into alternating current (AC) at high voltage. This high-voltage

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · Description This reference design realizes a reinforced isolated three-phase inverter subsystem using isolated IGBT gate drivers and isolated current/voltage sensors. The

A 13-level switched-capacitor-based multilevel inverter with

Jan 2, 2025 · The advantages of multilevel inverters include improved output voltage with low total harmonic distortion (THD), reduced voltage stress on switches, less need for filters, low dv/dt

Understanding inverter frequency – effects and

Oct 1, 2024 · In today''s world, inverters play a vital role in various applications, such as home solar power system, inverter for office use, inverter for van, etc.

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

The Technology Behind High Input Voltage Inverters

Feb 22, 2024 · This ensures the longevity and reliability of connected loads. In conclusion, high input voltage inverters have revolutionized the power conversion landscape. Their ability to

Comparison and Analysis of High Voltage Inverter and Low Voltage

Jul 28, 2022 · For testing high-voltage, large-capacity high-voltage inverters, due to the large voltage and current values, general instruments cannot meet the requirements. Voltage or

Comparison and Analysis of High Voltage Inverter and Low Voltage

Jul 28, 2022 · Adjustable output frequency AC motor drives with voltage levels below 690V are classified as low-voltage inverters. With the continuous maturity of low-voltage inverter

Inverters, Types and Voltages

Dec 31, 2024 · Understanding Low Voltage vs. High Voltage Inverters and Low Frequency vs. High Frequency Inverters. When setting up a solar energy system, choosing the right inverter

9. Inverter Settings

Sep 17, 2024 · To set the voltage at which the inverter restarts after low voltage shut-down. - To prevent rapid fluctuation between shut-down and start up, it is recommended that this value be

Voltage Troubles? A Guide to Diagnosing Inverter Low Voltage

Dec 17, 2023 · Properly grounding your inverter is crucial to avoid voltage fluctuations. In conclusion, inverter low voltage problems are not uncommon, but with the right knowledge and

4 FAQs about [Inverter output high voltage and low current]

What is a low cut-off voltage for an inverter?

The low cut-off of the inverter can be set at the load voltage of 170 volts for the tube light, fan, etc. So the tube light and fan will not be switched off until the voltage goes below 170 volts. If there is no load connected to the output of the inverter, the output voltage is 270 to 290 volts.

How to control the output voltage of inverters?

The most efficient method for controlling the output voltage of inverters is to introduce pulse width modulation (PWM). This method doesn't require any extra peripheral components and is an efficient and economical way compared to other methods.

What is the best inverter for CMOS?

•CMOS Inverters: Rabaey 1.3.2, 5 (Kang & Leblebici, 5.1-5.3 and 6.1-6.2) Amirtharajah/Parkhurst, EEC 118 Spring 2010 4 Vin Inverter Vout Vdd Vdd Vin Vout ideal actual Ideal digital inverter: Review: Inverter Voltage Transfer Curve

What does Vout mean in inverter?

– Point where voltage transfer curve intersects line Vout=Vin – Represents the point at which the inverter switches state – Normally, V M≈Vdd/2 – Sometimes other thresholds desirable Vdd

Learn More

- Tl494 inverter output voltage is low

- Azerbaijan high quality low voltage inverter price

- The inverter output high voltage drops instantly

- Inverter low frequency and high frequency

- Photovoltaic inverter high voltage grid connection

- Democratic Congo low voltage inverter manufacturer

- Is it normal for the inverter to output AC voltage 246V

- Inverter string output voltage

- High frequency inverter post-stage voltage stabilization components

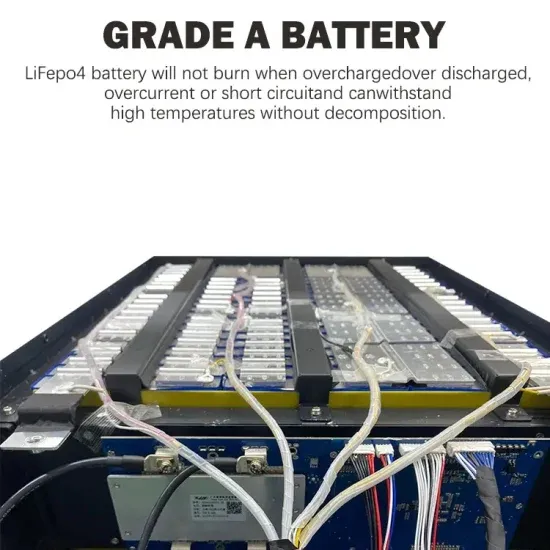

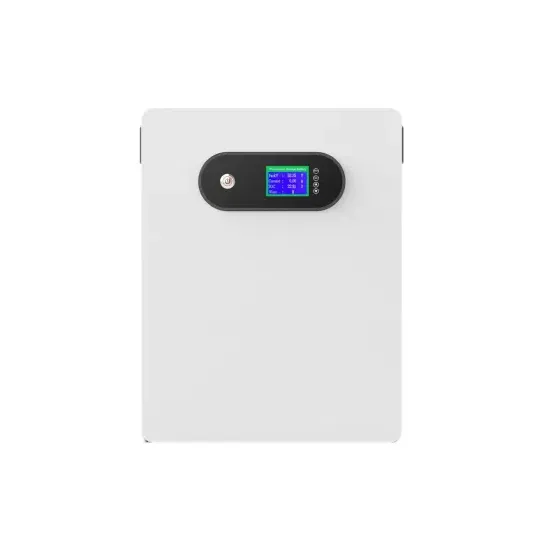

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.