AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · This process allows the inverter to control the motor''s speed and efficiency effectively. AC motor inverters utilize pulse width modulation (PWM) to create a variable

What is an inverter? | inverter

Aug 11, 2019 · The inverter is made of inverting circuit, logic control circuit and filtering circuit, mainly including input interface, voltage start circuit, MOS switch, PWM controller, DC

Inverter Protection and Ride-Through : RNWBL

Sep 22, 2022 · The inverter voltage control characteristic can be combined with a plant controller to provide Point of Interconnection (POI) voltage controls that

How does an inverter help stabilize voltage

Dec 26, 2024 · Inverters are power electronic devices that convert direct current (DC) to alternating current (AC). In certain applications, they can play a crucial

On Grid Inverter: Basics, Working Principle and Function

Jun 30, 2022 · A grid-tie inverter (GTI for short) also called on-grid inverter, which is a special inverter. In addition to converting direct current into alternating current, the output alternating

How does the inverter works ? – PCB HERO

Mar 5, 2025 · An inverter is an electronic device that converts direct current (DC) into alternating current (AC). This conversion is essential for powering AC devices (like household appliances)

How Power Inverter Generates Reactive Power

Nov 26, 2024 · Learn how power inverters generate reactive power to support voltage stability and enhance system efficiency. Understand the role of phase control and its importance for

Power Inverters: What Are They & How Do They

Dec 17, 2019 · What is an Inverter? An inverter (or power inverter) is defined as a power electronics device that converts DC voltage into AC voltage. While DC

How does an inverter control current?

Oct 26, 2021 · The two go hand-in-hand. If, on average, you''re providing slightly more current than the load sinks, the voltage will be increasing as you charge the output capacitance, since

Voltage and Harmonic Control of Inverters

Voltage and Harmonic Control of Inverters: Voltage and Harmonic Control of Inverters – In applying Inverters for motor control both V and f (keeping V/f constant) need to be varied.

HowTo: How an Inverter Drive Works and Controls the

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

6 FAQs about [How does the inverter control the voltage]

How does an inverter control a motor?

An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width modulation, or PWM. The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control.

How to control AC voltage in an inverter?

Basically, there are three techniques by which the voltage can be controlled in an inverter. They are, Internal control of Inverter. In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage.

What is voltage control of inverter?

Voltage control of inverters is employed in order to compensate for changes in input dc voltage. Basically, there are three techniques by which the voltage can be controlled in an inverter. They are, Internal control of Inverter.

How do inverter circuits work?

In this, the inverter circuit is fed from a constant dc voltage source and a controlled ac voltage is obtained at the output terminals by turning ON and OFF the switching components in the inverter circuit. The main drawback of this method is that it requires very low turn-ON and turn-OFF time thyristors which are very expensive.

What is internal control of inverter?

Internal control of Inverter. In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage. The block diagram representation of this method is shown in the below figure.

What is a control circuit in an inverter?

The control circuit regulates the operation of the inverter. It manages the frequency and voltage of the output AC power. This circuit includes various sensors and microcontrollers to ensure the motor operates at its optimal performance according to preset conditions.

Learn More

- Inverter AC voltage automatic control

- Inverter voltage space vector control

- How many meters is the high voltage inverter safe

- Inverter can control voltage

- How much is the price of Tskhinvali export inverter

- PQ control of grid-connected inverter

- How much does a 1000 watt 48v inverter cost

- EK dedicated inverter voltage

- Communication 48V inverter bus voltage

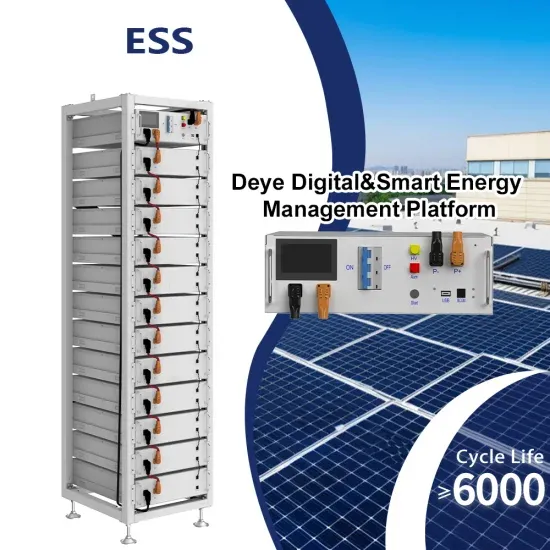

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.