A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · The advanced functionalities can be accomplished by using diversified and multifunctional inverters in the PV system. Inverters can either be connected in shunt or series

Dedicated Drives INVT Frequency Drive VFD for Industry

INVT dedicated drive has designed specific structure and function to provide safe, stable, and flexible products and solutions with reliable protection for compressor, photovoltaic pump and

A1500 series_Dedicated Inverter_Product_QMA Electric

Through the matching of motor speed and torque with the requirements of the driven load, variable speed transmission (VSD) has provided unprecedented performance for the motor

A860 series_Dedicated Inverter_Product_QMA Electric

A special product in the air compressor market.The product integrates a complete air compressor control process, which can not only drive asynchronous motors, but also drive permanent

EK θ multilevel inverter – a minimal switch novel

Oct 1, 2020 · However, the voltage across individual switches is high, and complex circuitry is the main drawback of this configuration. In [33], high

EK θ multilevel inverter – a minimal switch novel

Dive into the research topics of ''EK θ multilevel inverter – a minimal switch novel configuration for higher number of output voltage levels''. Together they form a unique fingerprint.

EK θ multilevel inverter – a minimal switch novel

Oct 1, 2020 · However, the voltage across individual switches is high, and complex circuitry is the main drawback of this configuration. In [33], high voltage rating switches and complexity of bus

FRENIC-Lift LM2A Starting guide

Jun 20, 2023 · General purpose inverters are subject to the regulations set forth by the Low Voltage Directive in the EU. Fuji Electric declares the inverters bearing a CE marking are

Solar panel dedicated charging inverter

The term " Inverter/Charger " or "Combined Inverter Charger" refers to a device used in solar energy systems that integrates the functions of a solar charge controller and an inverter into a

EK θ multilevel inverter – a minimal switch novel

Oct 1, 2020 · In this study, a new multilevel inverter (MLI) configuration is proposed to generate higher number of levels with minimal control switches. The proposed inverter''s nomenclature

THE MOST COMPLETE ENERGY STORAGE INVERTER

Energy storage inverter CE certification qualification Large batteries present unique safety considerations, because they contain high levels of energy. Additionally, they may utilize

On Grid Inverter: Basics, Working Principle and Function

Jun 30, 2022 · A grid-tie inverter (GTI for short) also called on-grid inverter, which is a special inverter. In addition to converting direct current into alternating current, the output alternating

A3000 series_Dedicated Inverter_Product_QMA Electric

It has automatic voltage adjustment, overvoltage and overvoltage speed control, fast current limiting, overvoltage protection, undervoltage protection, overcurrent protection, overheating

Output‐voltage feedback control topology for inverters dedicated

Apr 12, 2017 · Summary We present a new control topology for inverters, mainly dedicated to renewable energy applications. The originality is due to the integration in the inverter of an

A Compilation of the Best Power Inverters and

Oct 31, 2024 · The FR-A800 Plus series is a dedicated inverter line designed for specialized applications, building upon the high performance and functionality

How to modify a step-down converter to the inverting

Sep 12, 2023 · When looking for a DC/DC converter to create a negative voltage, in many cases you will use a step-down converter in the inverting buck-boost topology. While dedicated

6 FAQs about [EK dedicated inverter voltage]

What is multi-string transformerless solar inverter (EK-11 ek-100)?

Multi-string Transformerless solar inverters (EK-11 ~ EK-100) are suitable for commercial solar power generation market and public institution installment project. Rated output power is 11 ~ 100kW, wide MPPT range and input voltage are supported. It is a high-quality, high-reliability product with green certification technology.

Which solar inverter is best?

EKOS's EK-Series solar inverters combine the latest power electronics and IT technologies to provide the best in class performance and efficiency in its class. Multi-string Transformerless solar inverters (EK-11 ~ EK-100) are suitable for commercial solar power generation market and public institution installment project.

How do you connect a DC inverter to a 75k motor?

• For the 75K or higher inverters, or whenever a 75kW or higher motor is used, always connect a DC reactor. Connect the reactor to terminal P1 and P of the inverter. Make sure to remove a jumper across terminal P1-P before connecting. (A failure to do so will produce no power factor improving effect.)

What is a DC inverter?

Standard Specifications (Electrical Installation) (2013 revisions) supervised by the Ministry of Land, Infrastructure, Transport and Tourism of Japan.) A DC reactor connected on the DC side of the inverter improves power factor and reduces harmonic currents on the input side.

How do you connect a power supply to an inverter?

Remove the jumpers across the inverter terminals R/L1-R1/L11, S/L2-S1/L21, and connect the control circuit power supply to the R1/L11 and S1/L21 terminals. ∗1 Always keep the power input terminals R/L1, S/L2, T/L3 open. Incorrect connection will damage the inverter.

How to install a new inverter?

• When using a plug-in option, connect the plug-in option using a cable that can be routed through the space between the front cover and the control circuit terminal block (700 series: 7 mm, 500 series: 0.8 mm). When replacing with a new inverter, the attachment make the new inverter to be installed using holes of conventional model.

Learn More

- EK dedicated inverter price

- Inverter can control voltage

- Photovoltaic inverter voltage 315v

- Is it normal for the inverter to output AC voltage 246V

- Ottawa high voltage inverter manufacturer

- Inverter adjusts AC voltage

- The inverter output high voltage drops instantly

- Inverter output high voltage and low current

- 35kv high voltage inverter

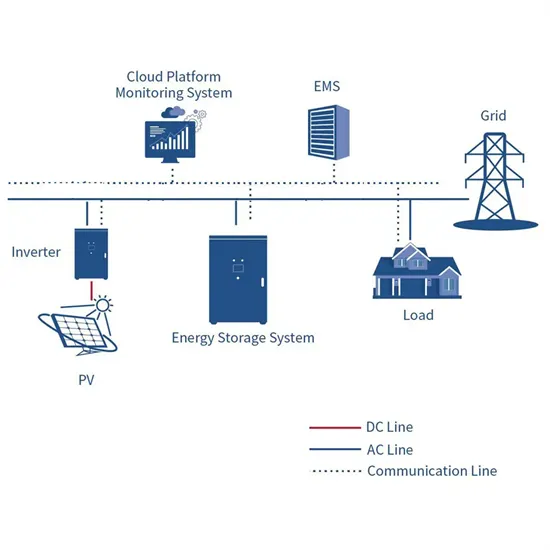

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.