AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · AC motor inverters utilize pulse width modulation (PWM) to create a variable voltage and frequency. In PWM, the inverter switches the power on and off rapidly, simulating

How does an inverter work?

Nov 26, 2019 · Purpose: To generate split-phase 120/240V AC, the inverter first needs a higher DC voltage (typically 300-400V DC) because the peak voltage of a 240V AC sine wave is

Synchronizing and Load Sharing in Inverter-Based

Nov 11, 2024 · The PLL continuously monitors the phase of the grid or other AC source voltage and adjusts the inverter''s output to align with it. This involves controlling the timing of the

Principle and application of frequency converter

Aug 21, 2024 · The inverter adjusts the voltage and frequency of the output power supply by changing the internal power switch (such as IGBT) to adjust the voltage and

Inverter Technology AC, Power Saving Split AC,

3 days ago · An inverter type air-conditioner adjusts the speed of the compressor to control the refrigerant (gas) flow rate, thereby consuming less current and

H Bridge Inverter Circuit using IC SG3525 and

Jan 9, 2025 · The SG3525-based H-Bridge inverter circuit converts low-voltage DC into high-voltage AC, making it ideal for use in applications like renewable

What''s the Difference Between an Inverter and a Variable-Speed AC

Dec 16, 2024 · Inverter technology and variable-speed AC systems are often mentioned together but refer to distinct components of modern HVAC systems. An inverter is an electronic device

Why Choose a Frequency Inverter? | inverter

The inverter adjusts the voltage and frequency of the output power supply by switching off the internal IGBT, and provides the required power supply voltage according to the actual needs

Inverter Saturation or "Clipping" – PV Performance Modeling

Inverter saturation, commonly referred to as "clipping", occurs when the DC power from the PV array exceeds the maximum input level for the inverter. In response to this condition, the

How Does A Grid-Tie Inverter Work?

Jan 29, 2025 · Synchronization: The inverter adjusts the AC output to match the grid''s frequency and voltage. Output Filtering: A filter smooths the waveform to produce a stable pure sine

[FREE] What is the function of an inverter? A) Changes DC to AC voltage

Oct 12, 2024 · An inverter is an electronic device that performs a crucial role in converting DC voltage (Direct Current) into AC voltage (Alternating Current). This conversion is essential for

Synchronizing and Load Sharing in Inverter-Based

The PLL continuously monitors the phase of the grid or other AC source voltage and adjusts the inverter''s output to align with it. This involves controlling the timing of the inverter''s switching

How does an inverter help stabilize voltage

Dec 26, 2024 · Inverters are power electronic devices that convert direct current (DC) to alternating current (AC). In certain applications, they can play a crucial

DC to AC Power Conversion Explained: Your Guide to Inverters

Jul 28, 2025 · Understand DC to AC power conversion, its role in energy systems, and how inverters enable compatibility between DC sources and AC devices efficiently.

Is it possible to adjust the inverters grid AC in voltage

Jun 27, 2024 · There is almost no room to adjust, max of the easysolar input is 265V, you could take a look at grid settings in VE configure. A step down transformer will work to bridge the

Does Inverter AC Need a Stabilizer? Know The

Jun 2, 2025 · Most modern inverter ACs, irrespective of the brand, come with an in-built stabilizer technology that protects them from voltage swings between

How Does An Inverter Work? | Its Components,

Jan 25, 2025 · A transformer in an inverter adjusts the voltage of the AC output to match the requirements of connected devices. After the DC is converted into

How Inverter Driven Compressors Work | A Guide for HVAC

Jun 26, 2025 · As HVAC contractors, understanding how inverter driven compressors work is essential for troubleshooting, maintenance, and explaining system benefits to your clients.

6 FAQs about [Inverter adjusts AC voltage]

How do inverters convert DC to AC?

Conversion process: Inverters initially take DC power from sources like batteries or solar panels. They use power electronic devices called transistors to switch the DC voltage rapidly. This switching creates a pulsed output that imitates AC waveform.

How to control AC voltage in an inverter?

Basically, there are three techniques by which the voltage can be controlled in an inverter. They are, Internal control of Inverter. In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage.

How do AC motor inverters work?

AC motor inverters utilize pulse width modulation (PWM) to create a variable voltage and frequency. In PWM, the inverter switches the power on and off rapidly, simulating an effective voltage. This method allows the inverter to control the required output efficiently. AC motor inverters also include feedback systems that monitor motor performance.

Why are inverters used in motor control applications?

When inverters are used to feed such ac loads, it is necessary that the inverters provide provision for voltage variations so as to supply the required voltage to ac loads. In motor control applications, inverters handle the control of circuit voltage along with frequency so that the saturation of motor magnetic circuits is avoided.

What is the function of inverter?

Inverter is to convert direct current (DC) to alternating current (AC), to provide a stable power supply for electrical equipment. It is mainly composed of two parts: oscillation circuit and step-up transformer. ● Voltage conversion: Converts low-voltage DC to high-voltage AC.

What is an inverter AC?

An inverter AC, as the name suggests, is a regular AC fused with inverter technology. For starters, an inverter is a device that converts DC (Direct Current) to AC (Alternating Current) or vice versa. So, an AC (Air Conditioner) with inverter technology can optimize its power consumption based on usage.

Learn More

- Industrial frequency inverter adjusts the working voltage

- Inverter adjusts voltage to 220

- Inverter AC voltage requirement

- Is it normal for the inverter to output AC voltage 246V

- Inverter high voltage main frequency or low voltage mixed frequency

- 12v inverter protection voltage change

- Inverter rated phase voltage

- Three-phase inverter grid-connected voltage range

- Can the DC 12V voltage be supplied to the inverter

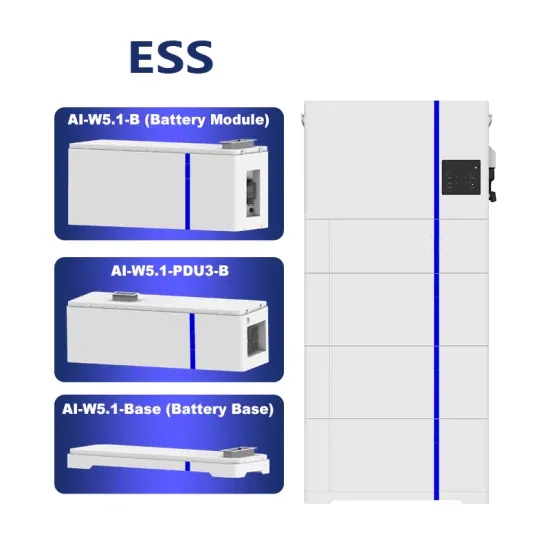

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.