48V Automotive Systems: Why Now?

Feb 6, 2025 · In this paper, we discuss the growing interest in 48V low-voltage rail systems for electric and hybrid vehicles and how engineers can use them to reduce wire harness size and

EG4 6000XP Communications not possible with Eco-Worthy server rack 48v

Jun 21, 2025 · You can however use just about any 48v battery including Eco Worthy without comms by selecting lead acid battery type on the inverter and manually setting the charging

AN-Power stage of 48V BSG inverter

Sep 9, 2021 · Scope and purpose The power stage was developed to support customers during their first steps in designing 48V inverter for Belt-driven Starter Generator (BSG) application.

SK48V100 Owner & Operator''s Manual

Sep 4, 2024 · A 16S (48v nominal) 5.12 kW-h LiFePO4 battery bank is paired with a digital battery management system (BMS), to provide automated and maintenance free battery operation,

48V, 85A Small Form-Factor Three-Phase Inverter

May 31, 2025 · Working with a digital sinc three decimation filter in the MCU, the linear current measurement range reaches ±167A. Additional feedback includes the DC-bus voltage and the

CAN Bus Protocol for Battery Communications

Jun 8, 2023 · CAN Bus Interface Configuration: The inverter only recognizes standard CAN Bus frames containing 8 bytes of data. CAN FD with 64 data bytes is not supported.

48V in automotive design resources | TI

Aug 12, 2025 · A 48V low-voltage power net helps with advancements in autonomous driving and vehicle electrification by increasing electrical power capacity and reducing wire harness cost

Hybrid Inverter Wiring and Configuration Insights

4 days ago · Confirm your inverter''s working voltage (many lithium setups use 48V) Make sure your lithium battery''s communication method works with the inverter (usually CAN bus or

Interfacing Lead Acid batteries with inverter

Apr 26, 2022 · The data sheet says lead-acid is supported. Yes, it is, but lead acid don''t have CAN BUS for communication. I was wondering whether those need some kind of interface

Hybrid Inverter Wiring and Configuration Insights

4 days ago · Confirm your inverter''s working voltage (many lithium setups use 48V) Make sure your lithium battery''s communication method works with the inverter (usually CAN bus or

wp-Re-Architecting-48V-Power-Systems.pdf

Sep 9, 2021 · Owing to the bidirectional start up and control of the SACTM implementation [f] [g], the proposed bus converter can be utilized to create a local, higher voltage, higher efficiency

Low Voltage Inverter for 2/3 Wheeler Traction Motor Control

2 days ago · This low voltage inverter for 2/3 wheeler traction motor control features an MCU and analog products, designed for high-power 48V motor control applications. The design includes

Communications System Power Supply Designs

Apr 1, 2023 · A VoIP DC-DC converter uses a less complex single high-power output transformer design (typ. 250-500W) to buffer the main -48V distribution bus. This minimizes the cost and

4 FAQs about [Communication 48V inverter bus voltage]

What is a 48 volt intermediate bus converter (IBC)?

48 V intermediate bus converter (IBC) Overview Hybrid switched-capacitor converter (HSC) Zero-voltage-switching switched capacitor converter (ZSC) AI accelerator cards AMD server CPUs Ampere CPUs FPGAs in datacenter applications Intel server CPUs Networking and switch platforms Power path protection Power system reliability modeling RAID storage

What is the intermediate bus voltage in the two-stage architecture?

The intermediate bus voltage in the two-stage architecture is evaluated by designing two LLC-DCX converters with fixed transformation ratios of (4:1) and (8:1). The overall efficiency of the two-stage architecture is evaluated, and the optimal bus voltage is selected.

What types of power converters & inverters are used for wind turbines?

Photovoltaic Power converters and inverters for wind turbines Solid-state circuit breaker All Applications Robotics Robotics Overview

How many volts a starter generator – inverter?

Crankshaft starter generator 48 V – inverter ISG DC-DC converter 48 V-12 V Driveline starter generator 48 V – inverter ISG All Applications

Learn More

- What is the maximum voltage of a 48v inverter

- Communication inverter 48V to 220V

- Communication base station inverter construction enterprise

- The inverter for Moldova s communication base station is connected to the grid by Huawei

- Prague photovoltaic inverter output voltage

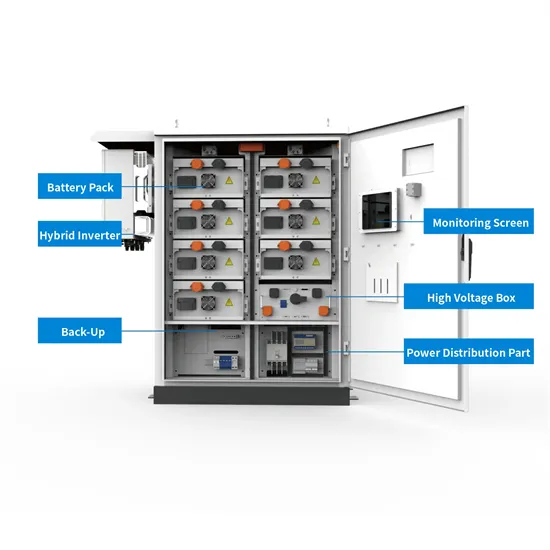

- Working Principle of Communication High Voltage Energy Storage Cabinet Site

- Inverter adjustment voltage range

- Outdoor communication base station inverter grid connection

- Wind power communication base station inverter grid-connected energy storage cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.