MPP Solar Inc » Inverter Selection Guide

6 days ago · While not necessarily applicable to all inverters, most small output inverters are designed in 12v, and as output increases, the demand for system voltage is raised to 24v or

Understanding the Cut-off Voltage for a 48V Battery:

Aug 20, 2024 · The cut-off voltage for a 48V battery typically ranges from 42V to 44V. This is the minimum voltage at which the battery should be discharged to prevent damage and ensure

Backup Time of 100Ah 48V Lithium Batteries Introduction

Oct 9, 2024 · To calculate the backup time (T) of a 100Ah 48V lithium battery, we first need to calculate the total energy (E) stored in the battery. The energy can be calculated using the

Inverter Battery Voltage: How Many Volts Are Needed For

Mar 27, 2025 · An inverter battery typically operates at 12V, 24V, or 48V. These voltages represent the nominal direct current (DC) needed for the inverter''s function.

Understanding the Normal Working Voltage of a 48V Inverter

What Is the Normal Operating Voltage Range for a 48V Inverter? When discussing 48V inverters, one of the most common questions is: "What''s the normal working voltage?" Simply put, a 48V

The Differences Between 24v and 48v Inverter:

Apr 13, 2025 · 24V and 48V inverters have different input voltages, and inverters with different voltages must be matched to the correct equipment. If your TV

Inverter DC ripple voltage specification

Mar 21, 2022 · I''m trying to get some clarity on the DC ripple specifications relating to Victron inverter/chargers. There is contradictory data in different places, and a lack of clarity, not to

What size fuse between battery and inverter?

Apr 22, 2024 · Step 1: determine the maximum amount of current your inverter is going to pull (at the lowest battery voltage) and multiply it by 1.25 to find the

48V Solar Inverters: 2025 Buyer''s Guide & Top

Apr 3, 2025 · A 48V solar inverter converts direct current (DC) generated by solar panels into alternating current (AC), specifically designed for 48V battery

EG4® FLEXBOSS21 HYBRID INVERTE

Aug 7, 2025 · Y B R I D I N V E R T E R The EG4 FlexBOSS21 is a versatile 48V split-phase, hybrid inverter/charger that offers the same dependable power as the 18kPV with enhanced

Calculate Battery Size For Any Size Inverter

Mar 3, 2023 · Battery size chart for inverter Note! The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter,

A Complete Overview of 48V Batteries and Their

May 30, 2025 · This comprehensive guide delves into the voltage levels, capacity considerations, and practical applications of 48V batteries, providing valuable

How Many Batteries For A 5KVA/48V Inverter? Answered

Sep 2, 2022 · Depending on the maximum voltage of the charge controller, the system will need at least 2 panels in series while charging 48V batteries. Still, it will function considerably better

For a 48v system what voltage panels are needed

Dec 22, 2020 · Open Circuit Voltage (Voc), which is the maximum voltage that the panel can achieve at maximum illumination under ideal conditions at some "normal" temperature.

EG4® 12kPV HYBRID INVERTE

Mar 10, 2025 · Y B R I D I N V E R T E R The EG4 12kPV is a 48V split-phase, hybrid inverter/charger capable of utilizing 12kW of PV input and efficiently outputting 8kW of power

Understanding inverter voltage

Jan 10, 2024 · Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function

What is the maximum input voltage of a 48v inverter

Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V, or 48V. Input Current: determines the

When to Use a 24V or 48V Battery System Instead of a 12V

But 960W would be our limit with 24 volts. If we need more power, we then would have to increase our voltage to 48V. This could be achieved either with a 48V battery or 2 24V

Multiplus II 48V/5000: Absolute maximum charging voltage

Jun 4, 2024 · Multiplus II 48V/5000: Absolute maximum charging voltage that can be set? The Multplus II 48V/5000 datasheet states a maximum charging voltage of 64 volts, and a

6 FAQs about [What is the maximum voltage of a 48v inverter ]

How many volts can a 48 volt inverter run?

Some 48v systems have a 150v limit, and others have 500v or more. In general, you can put in series as many panels as you want to want, up to the limit. Whether they be 36 or 72 cell panels. Just be careful of minimum voltage, especially with 150v max inverters.

What is a 48v battery?

The term “48V” refers to the nominal voltage, which is the average voltage during use. However, the actual voltage of a battery system will vary throughout the charging and discharging cycle. Nominal Voltage: 48V is the average working voltage of the system. Maximum Voltage: The highest voltage reached when the battery is fully charged.

Do I need a 12V or 48V inverter?

Simply put, if you have a 12V system, you need a 12V inverter; a 48V system requires a 48V inverter. Standard Pure Sine Wave inverters simply change DC power to AC power. Inverter Chargers handle this function plus allow you to charge your batteries off shore power or a generator. Renogy’s 3500W Solar Inverter Charger is designed for a 48V system.

What voltage is a 12V inverter?

Inverters come in various configurations, each designed for specific power systems. Common rated input voltages include 12V, 24V, and 48V. The choice depends on the application, the size of the power system, and the available power source. A 12V inverter is commonly used for smaller applications, such as in vehicles or small off-grid setups.

What is the input voltage of an inverter?

Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function optimally. What is the rated input voltage of an inverter?

How many volts does an inverter need?

For grid-tied systems, this is typically 220V or 230V in most countries. For off-grid systems, it might be 48V or 24V, depending on your battery configuration. Ensuring this rating matches your power system's output guarantees that your inverter will efficiently convert energy without risk of damage.

Learn More

- What is the maximum power of a 12v high power inverter

- What is the best voltage for a power frequency inverter

- What is the inverter output voltage

- What is the voltage of each string of the inverter

- What brand of 48v inverter is good in Bergen Norway

- The maximum grid voltage that the inverter can withstand

- What is the voltage of a 60v inverter

- Does the inverter have high voltage

- Inverter bridge arm midpoint voltage

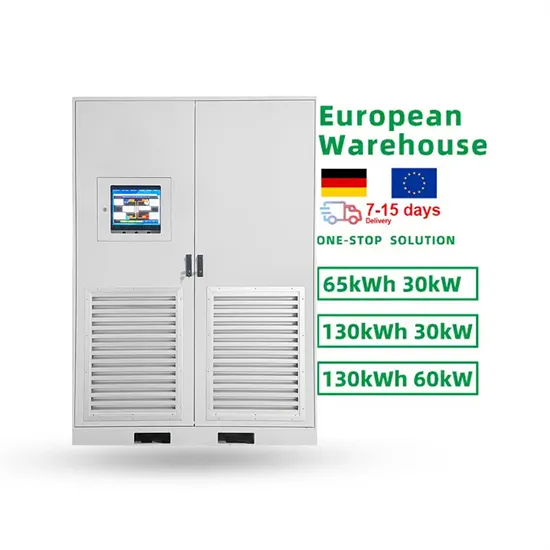

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

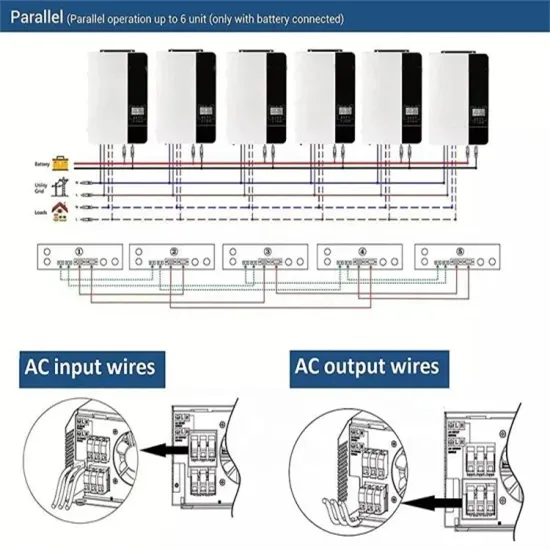

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.