Mastering Inverter Switching Frequencies: A

Apr 25, 2024 · The switching frequency of inverters in electric motor applications is critically controlled to optimize performance, efficiency, and minimize noise

Understanding inverter frequency – effects and adjustments

Oct 1, 2024 · In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per second. This inverter frequency is

Understanding Inverter Voltage: Definition,

Dec 16, 2024 · Inverter voltage is a voltage generated by the inverter after several electrons that converts a series of direct current (DC) into alternating current

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · When selecting a frequency inverter, consider the following factors: Power Requirements: Determine the voltage and wattage needed for your application. Load Type:

Frequency Inverter Basic: Introduction, Functions

Dec 11, 2023 · The frequency inverter is a power control equipment that applies frequency conversion technology and microelectronics technology to control

High Frequency Inverter vs low Frequency Inverter

Introduction What is a High Frequency Inverter? What is a Low Frequency Inverter? Introduction By the early 1980s, pure sine wave inverters had become more commercially available,

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width

Understanding Low Frequency Power Inverters

6 days ago · The Understanding Low Frequency Power Inverters: A Comprehensive Guide is an in-depth resource for anyone interested in the design, construction, and operation of low

Ultimate Guide to Choosing the Best Frequency Inverter for

Jun 14, 2025 · This ultimate guide will explore the industry standards associated with frequency inverters, highlight common problems encountered during selection, and offer insights into

How to Select the Right Frequency Inverter for Your Needs

Match Motor Type and Inverter Your motor and inverter must work well together. First, make sure the inverter''s voltage, current, and frequency fit your motor. Then, check the control method,

6 FAQs about [What is the best voltage for a power frequency inverter ]

What is a standard inverter frequency?

In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per second. This inverter frequency is essential for the proper functioning of electrical devices and systems, as it dictates the speed at which motors rotate, lights flicker, and electronic components operate. 2.

How to choose a frequency inverter?

1. Appropriate Frequency Range for Different Applications One of the most critical aspects of frequency inverter operation is selecting the right frequency range for the specific application. For most industrial applications, the standard range of 0-50Hz is sufficient, especially for typical motors.

What is AC inverter frequency?

1. What is the frequency of AC inverter? An AC inverter frequency refers to the number of power signal fluctuations, typically measured in Hertz (Hz). In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per second.

How do frequency inverters work?

At their core, frequency inverters are sophisticated devices that modify the frequency of the electrical supply to a motor, transforming it from a constant value to a variable one. This is done through a two-step process. First, the incoming AC power is converted into DC power via a rectifier.

Can a frequency inverter run a motor above 50Hz?

While most motors are designed to operate at a frequency of 50Hz, there are many situations where higher speeds are necessary. Frequency inverters provide the flexibility to run motors above 50Hz, allowing for increased operational speeds and improved performance in certain applications.

Should you use a frequency inverter to control motors?

Using frequency inverters to control motors offers numerous advantages, but it also requires careful consideration to ensure optimal performance, longevity, and efficiency. Here are some key factors to keep in mind when implementing a frequency inverter system: 1. Appropriate Frequency Range for Different Applications

Learn More

- Dual voltage power frequency inverter

- What is the best power for a 12v inverter

- Inverter voltage of power frequency inverter

- What is the voltage of each string of the inverter

- Power frequency pure sine wave inverter 2

- What is the maximum voltage of a 48v inverter

- Power frequency inverter off-grid

- Assembly of high power industrial frequency inverter

- 5kva high frequency power inverter

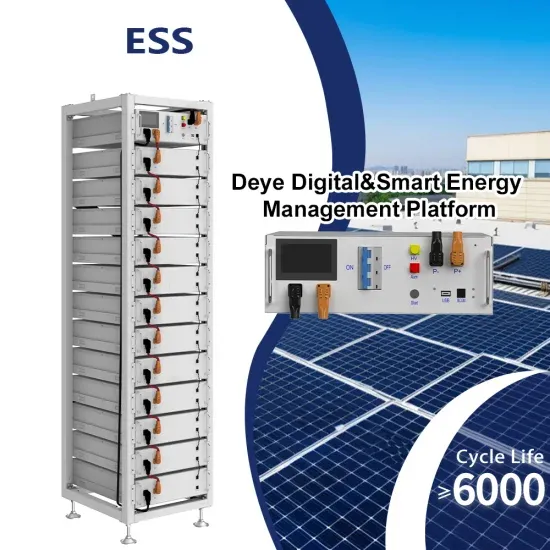

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.