Design Procedures and Prototyping of a Full-Bridge High Frequency Power

Dec 4, 2019 · Design Procedures and Prototyping of a Full-Bridge High Frequency Power Inverter Published in: 2019 IEEE 15th Brazilian Power Electronics Conference and 5th IEEE Southern

Demystifying high-voltage power electronics for solar

Apr 1, 2023 · One of the key subsystems in PV generation is the inverter. Advancements in high-voltage power electronics are resulting in more intelligent, more lossless and smaller PV

Understanding High-Frequency Inverters

6 days ago · In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

High Frequency Inverter: Advanced Power Control Solution for Industrial

The high frequency operation allows for smaller transformer sizes and reduced magnetic components, resulting in a more compact and lightweight design. These inverters incorporate

Introduction to inverters: structure, operating

May 24, 2024 · Currently, devices commonly used in inverters include insulated gate bipolar transistors (IGBTs), power field effect transistors (MOSFETs),

Understanding inverter frequency – effects and

Oct 1, 2024 · Understanding inverter frequency – effects and adjustments In today''s world, inverters play a vital role in various applications, such as home

A High Frequency Inverter for Variable Load Operation

Dec 4, 2023 · This paper presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter that is able to directly drive widely variable

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The first step is the conversion of the low voltage DC power to a high voltage DC source, and the second step is the conversion of the high DC source to an AC waveform using

The Role of Frequency Inverters in Modern Industry

The integration of frequency inverters with IoT and smart systems is revolutionizing industrial operations. Modern frequency inverters now feature connectivity options that allow seamless

High-Frequency vs. Low-Frequency Inverters

High-Frequency vs. Low-Frequency Inverters Inverters are crucial components in solar power systems, uninterruptible power supplies (UPS), and other electrical systems. Their job is to

Design and Manufacturing Modular Inverter with High Power and Frequency

In this research, a modular inverter with high frequency and power and the capability to determine the type of output (complete sine or square) and select the inverter phase (single phase or 3

A High Frequency Variable Load Inverter Architecture

Jul 5, 2021 · This thesis presents a high frequency variable load inverter architecture along with a physical prototype and e ciency optimizing controller. The inverter architecture consists of two

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · There are two distinct types of industrial grade power inverters distinguished by the size of their transformers, and the switching speed of their transistors. The ability of an inverter

High-precision Power Measurement of SiC Inverters

Jan 16, 2023 · Accurate power measurement is a critical precondition for eval-uating motor drive systems, but power measurement of SiC inverters requires high-precision measurement

Streamlining Inverter Reliability with Precision PCB Assembly

Mar 13, 2025 · Modern industrial environments demand PCB assembly (PCBA) solutions that balance high-power performance with operational resilience. For inverters powering critical

Exploring Commercial Uses of High-Frequency Inverters

4 days ago · High-frequency inverters have emerged as a powerful technology, gaining increasing prominence in various commercial applications. Their exceptional features, including compact

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · If you are looking for an inverter for fixed power stations, precision instruments, or other related fields, then go with power-frequency inverters. However, a high-frequency

Efficient PCB Assembly Solutions for Inverter

Feb 28, 2025 · This article explores efficient PCB assembly solutions tailored for inverter technologies, highlighting the latest methods, materials, and practices

Design and Manufacturing Modular Inverter with High Power and Frequency

Feb 28, 2019 · The considerable advances in semi-conductors technology and emergence of power transistors with high voltage, switching and frequency has led to optimizing the

6 FAQs about [Assembly of high power industrial frequency inverter]

What is a high frequency inverter?

High-frequency inverters generate the AC output waveform by switching power devices at frequencies much higher than the output frequency. Some key characteristics: They contrast with line-frequency inverters operating nearer to the AC output frequency. [Diagram] The inverter bridge contains power switches like IGBTs or MOSFETs.

What is a high frequency variable load inverter architecture?

This thesis presents a high frequency variable load inverter architecture along with a physical prototype and e ciency optimizing controller. The inverter architecture consists of two constituent inverters, one connected directly through the load and the other connected through an immittance converter, which acts as a lossless power combiner.

What are common high-frequency inverter circuit configurations?

Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs. Filter components – Smaller inductors and capacitors possible at high frequencies. Balance size versus performance.

Can a high-frequency variable load inverter directly drive widely variable loads?

Typically a tunable matching network is used to transform the varying load into a ciency and impairing transient response. This thesis presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter architecture (referred to as HFVLI) that can directly drive widely variable loads.

What is the ciency of a RF inverter?

rst physical prototype of of a wide load range RF inverter based on the proposed high frequency variable-load inverter topology was designed and built along with an e ciency optimizing controller. ciency of 95.4%.

What determines the output frequency of a high-frequency inverter?

The output frequency depends on how fast the switches cycle on and off. Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs.

Learn More

- New generation of intelligent industrial frequency high power inverter

- High power industrial frequency inverter

- The difference between inverter and high frequency power generation

- Inverter power frequency high frequency

- Power frequency solar off-grid inverter high power

- Can the inverter high frequency be used with 50hz appliances

- What is a high frequency inverter

- Algeria industrial frequency pure sine wave inverter

- Can a high frequency inverter 24v be converted to 48v

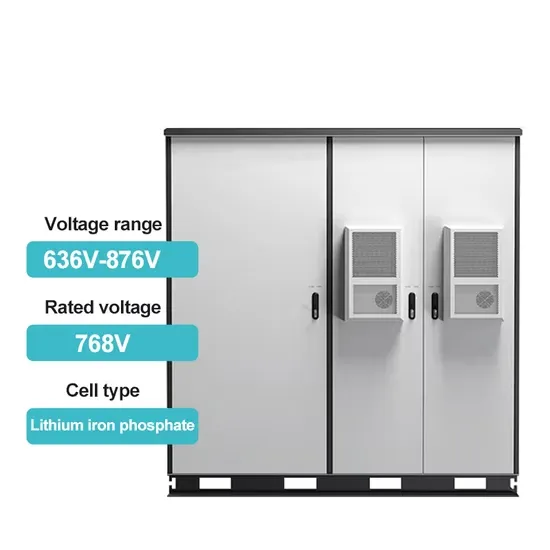

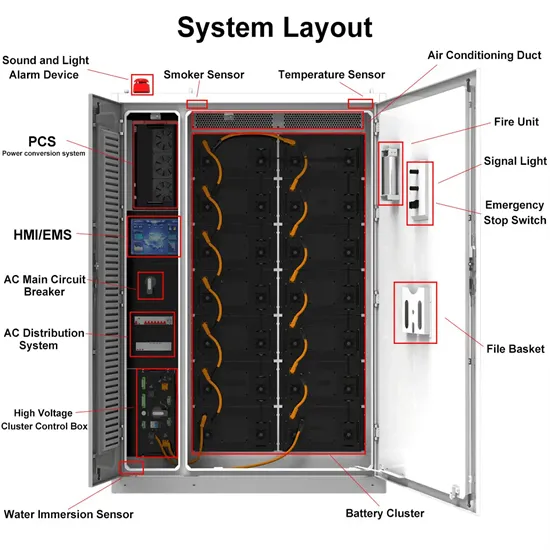

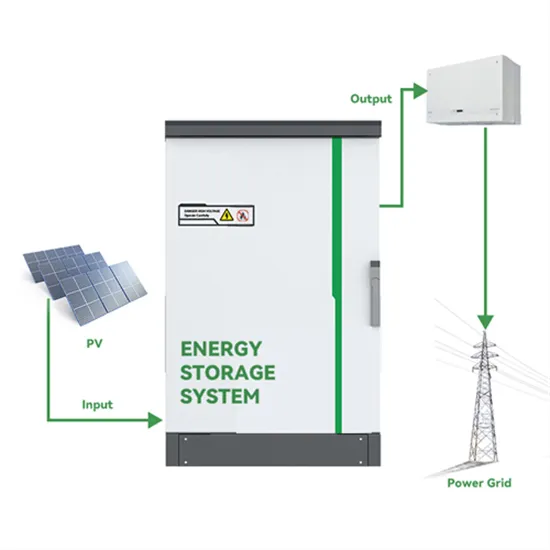

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.