The Difference Between High Voltage Converters and Inverters

Dec 4, 2024 · Power electronic devices, like high voltage converters and inverters, are valuable features of electrical systems. They silently manage energy flows, optimize power usage, and

AN INTRODUCTION TO INVERTER-BASED RESOURCES

Jul 5, 2023 · Inverter-based resources are now found everywhere across the bulk power system (BPS) in North America and are the most significant driver of grid transformation today. This

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · A high-frequency filter that is connected to the power supply side or load side of an inverter to absorb noise that is generated in an inverter when a power device switches.

What are the differences between high-frequency inverter and power

Jul 22, 2025 · An inverter is a device that converts direct current (DC) to alternating current (AC) to meet the power demand of AC load. According to the topology, the inverter can be divided

Frequency Inverter Basic: Introduction, Functions

Dec 11, 2023 · The frequency inverter is a power control equipment that applies frequency conversion technology and microelectronics technology to control

The difference between power frequency inverter and high frequency

Mar 13, 2025 · High-frequency inverter power supply first through high-frequency DC/DC conversion technology, the low-voltage direct current inverter into high-frequency low-voltage

Low frequency inverter vs high frequency

Mar 12, 2025 · In this article, we''ll explore their differences, benefits, and ideal use cases to help you make an informed decision. Understanding the Difference

What is the Difference Between High and Low Frequency UPS?

Mar 27, 2025 · A high-frequency UPS is lightweight, efficient, and ideal for offices, IT infrastructure, and small to medium-sized businesses. On the other hand, a low-frequency

Introduction to Grid Forming Inverters: A Key to

Jun 18, 2024 · Difference between Synchronous Generators and Inverter-based Resources (IBRs) Conventional power plants use large rotating synchronous generators to produce electricity

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · High-frequency inverters consume less power from the battery at zero load than power-frequency inverters. Power-frequency inverters are best for their robustness and

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · 29.1 Introduction Photovoltaic (PV), wind, and fuel-cell (FC) energy are the front-runner renewable- and alternate-energy solutions to address and alleviate the imminent and

What is the Difference between Hybrid Inverter

Feb 20, 2024 · Energy demand: Scenarios with high energy demand and stable power grid are suitable for grid-connected inverters; while scenarios with large

Pure Sine Wave Inverter: All You Need to Know

May 10, 2023 · In this blog post, we will explore the fundamentals of pure sine wave inverters, including what they are, how they work, the differences between modified and pure sine wave

Understanding inverter frequency – effects and

Oct 1, 2024 · Understanding inverter frequency – effects and adjustments In today''s world, inverters play a vital role in various applications, such as home

An Overview of Grid-Forming Inverter Technologies and

HIERARCHY OF MODERN IBR CONTROLS Most modern renewable energy resources such as wind generation, photovoltaic (PV) generation, batery energy storage systems (BESS),

Difference between On Grid Inverter and Off

Feb 13, 2021 · On-grid solar inverters are tailored for grid-connected renewable energy systems, while off-grid solar inverters, such as the 2000W off-grid solar

Grid-Forming Inverters vs. Synchronous Generators:

Jan 23, 2023 · Abstract—Traditional power system frequency dynamics are driven by Newtonian physics, where the ubiquitous synchronous generator (SG) maps second order frequency

The difference between a high and low frequency inverter

Dec 17, 2024 · Understanding the differences between a high and low frequency inverter helps you make informed decisions. High frequency inverters offer compactness and efficiency,

6 FAQs about [The difference between inverter and high frequency power generation]

What is a high frequency inverter?

High frequency inverter: High frequency inverters use high-frequency switching technology to chop DC power at high frequency through high-frequency switching tubes (such as IGBT, MOSFET, etc.), and then convert high-frequency pulses into stable alternating current through high-frequency transformers and filter circuits.

What is the difference between high frequency and low frequency inverters?

Here is the major difference of them: Thanks to the heavy-duty transformer, low frequency inverters have much higher peak power capacity and reliability. The transformer handles higher power spikes with longer duration than high-frequency inverters when it comes to driving inductive loads such as electric motor, pump, compressor, air conditioners.

What are the advantages of high frequency inverters?

Volume and weight: Since high frequency inverters use high-frequency switching technology and compact circuit design, their size and weight are usually much smaller than power frequency inverters. This gives high frequency inverters significant advantages in mobile power supplies, aerospace, electric vehicles, and other fields.

Are high-frequency inverters a good choice?

Due to the use of high-frequency switching technology, high-frequency inverters have the advantages of small size, lightweight, and high efficiency, but they also have the problem of relatively poor output waveform quality.

Are power frequency inverters good?

In contrast, power frequency inverters can maintain high efficiency and stability under heavy load or overload. Output waveform quality: The output waveform quality of power frequency inverters is usually better than that of high frequency inverters.

How do I choose a low frequency or high frequency inverter?

When deciding between a low frequency or high frequency inverter, it is important to consider the power requirements of the appliances and devices that you wish to power. Heavy-duty items, such as air conditioners and refrigerators, may require a low frequency inverter with high surge capacity.

Learn More

- New generation of intelligent industrial frequency high power inverter

- 5kva high frequency power inverter

- 1kW high frequency inverter power consumption

- Power frequency solar off-grid inverter high power

- Inverter power frequency high frequency

- Laayoune power generation energy storage and frequency regulation

- High frequency resonant inverter

- High frequency inverter 2025

- Eritrea High Frequency Inverter

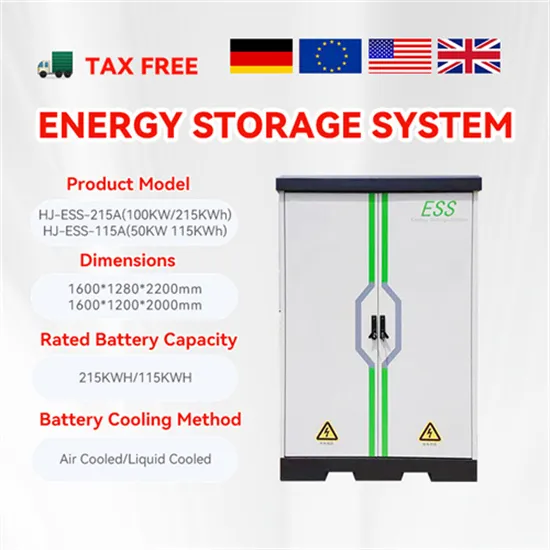

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.