Review on Silicon Carbide-Based High-Fundamental Frequency Inverters

Jun 18, 2025 · The analysis identifies a research gap in the development of high-power inverters (greater than 1 MW) capable of operating above 1 kHz fundamental frequencies. The paper

Understanding inverter frequency – effects and

Oct 1, 2024 · Understanding inverter frequency – effects and adjustments In today''s world, inverters play a vital role in various applications, such as home

Ultimate Guide to Choosing the Best Frequency Inverter for

Jun 14, 2025 · This ultimate guide will explore the industry standards associated with frequency inverters, highlight common problems encountered during selection, and offer insights into

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · There are two distinct types of industrial grade power inverters distinguished by the size of their transformers, and the switching speed of their transistors. The ability of an inverter

Industrial Frequency Converter Manufacturer, Custom Inverter

According to the characteristics of various industries, MICNO industrial frequency converter has designed specific structure and function to provide safe, stable, and flexible products and

The difference between industrial frequency inverter and high frequency

Jan 6, 2021 · The high-frequency inverter first uses high-frequency DC/DC conversion technology to invert low-voltage direct current into high-frequency and low-voltage alternating current;

High Frequency Power Inverters: A Guide To Modern Solutions

May 4, 2024 · High frequency power inverters, also known as HFPI, are devices that convert direct current (DC) into alternating current (AC) at a higher frequency than traditional power

High Frequency Inverter for Industrial Applications

High frequency inverters play a critical role in modern industrial applications, converting DC power into high-frequency AC power for a wide range of machinery and equipment. These inverters

ABB central inverters

Oct 4, 2013 · Solar inverters from ABB ABB central inverters are ideal for large photovoltaic power plants and medium sized power plants installed in commercial or industrial buildings. High

Understanding High-Frequency Inverters

6 days ago · In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · In the energy electronics and conversion industry, inverters are the main driver for power conversion, playing a significant role. Inverters have the potential to transform the direct

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · A frequency inverter, also known as a variable frequency drive (VFD), is an essential device used to control the speed and torque of electric motors by adjusting the input

The Role of Frequency Inverters in Modern Industry

The integration of frequency inverters with IoT and smart systems is revolutionizing industrial operations. Modern frequency inverters now feature connectivity options that allow seamless

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied

High-efficiency DC/AC inverter, High-efficiency inverter

Find your high-efficiency dc/ac inverter easily amongst the 85 products from the leading brands (INVT, VEICHI, SALICRU,) on DirectIndustry, the industry specialist for your professional

High Frequency Inverter: Advanced Power Control Solution for Industrial

Discover our cutting-edge high frequency inverter featuring superior efficiency, precise power control, and comprehensive protection systems. Ideal for industrial applications requiring

Industrial Frequency Inverters: Advanced Motor Control

Discover high-performance frequency inverters featuring advanced energy management, comprehensive protection, and smart connectivity for optimal motor control and energy

6 FAQs about [High power industrial frequency inverter]

What is high frequency power inverter?

The high voltage frequency converter integrate the most advanced motor vector control algorithm, high control precision, fast response, low frequency, high torque. Our high frequency power inverter can be applied to energy-saving speed regulation and process improvement of high-voltage asynchronous motors and synchronous motors.

What is a high efficiency inverter?

High Efficiency The high efficiency and automatic economy mode are designed to allow digital clocks to work properly and ensure you many more hours of operation from your batteries. IPower-Plus is a high - frequency pure sine wave inverter that can convert 12/24/48VDC to 220/230V AC and power the AC loads.

What is a high frequency inverter welding machine?

The inverter circuitry can also provide features such as power control and overload protection. The high frequency inverter-based welding machines are typically more efficient and provide better control of variable functional parameters than non-inverter welding machines.

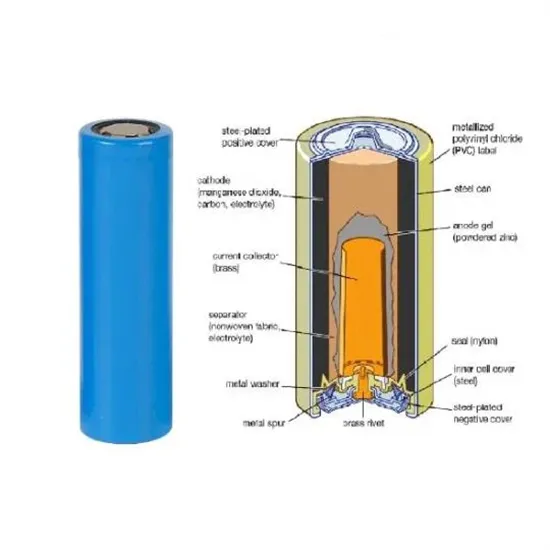

What are the parts of a high frequency power inverter?

The high frequency power inverter includes two parts, main circuit and control circuit. The main circuit includes an inverter DC power supply, high frequency high voltage transformers, IGBT bridge inverter, protection circuits, high frequency high voltage silicon stack (Rectifier) , etc.

How much does a high frequency inverter weigh?

That unit (Phocos PSW-H 5kw/120v) weighs around 110 lbs. I'm also considering it for my off-grid build, but I believe high frequency inverters generally weigh less and can double power on a surge for a couple seconds.

What is micno high voltage inverter?

MICNO high voltage inverter adopts the most mainstream power unit series technology, with DSP+ARM+FPGA three-core processor as the control core. The high voltage frequency converter integrate the most advanced motor vector control algorithm, high control precision, fast response, low frequency, high torque.

Learn More

- Assembly of high power industrial frequency inverter

- High power industrial frequency inverter

- The difference between inverter and high frequency power generation

- Inverter power frequency high frequency

- Niamey high frequency power inverter

- Power frequency solar off-grid inverter high power

- Grid-connected inverter high power

- High frequency inverter post-stage voltage stabilization components

- Hungary Pecs high frequency inverter

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.