Isolation Transformer Frequency Conversion 230V (50Hz)

Jun 27, 2022 · You don''t really need to change the frequency. Most 60Hz appliances will run on 50 Hz - only motor driven appliances will work a little more slowly. If you do need to change

Frequency Converter vs Inverter

Oct 22, 2024 · In today''s modern industrial and commercial settings, devices like frequency converters and inverters are essential for controlling and optimizing the performance of various

Convert 50 To 60Hz, 60 To 50Hz, Or Either To 400Hz

Jul 22, 2025 · The method I used to obtain either 50Hz or 60Hz from 60Hz or 50Hz (respectively) is somewhat unusual, but it works perfectly and synchronises the ''new'' frequency directly from

Understanding the effects of frequency on appliances

Aug 28, 2020 · Some appliances care, some don''t. AC induction motors run in sync with the line frequency (less a few percent of ''slip'', depending on load.) This is set by the number of poles

CE ROHS Certified 2000W True Sine Wave Inverter Grid DC

· Marine and industrial gradeThe 2000 watt 48 volt low frequency Power inverter charger transforms DC (direct current) power, stored by batteries, into AC (alternating current)

50Hz vs 60Hz Inverters How to Choose the Right Frequency

Summary: Confused about whether to use a 50Hz or 60Hz inverter? This guide breaks down regional standards, industry applications, and technical trade-offs. Learn how frequency

60 Hz to 50 Hz frequency transformer/inverter

Feb 3, 2023 · I need to transform the frequency from 60 Hz (220 V) to 50 Hz (220 or 230 V). Alternatively I can use 110 V, 60 Hz for the required output. I''m looking to find a cost and

Inverter design using high frequency

Feb 27, 2021 · In this paper we are developing inverter which is very cheap in cost and portable we are using 50KHz frequency for DC Technique and output 250V DC, 500mA, 100watt and

Inverter Low Frequency vs High Frequency | How Do I

Mar 31, 2024 · Low-frequency inverters operate at a frequency of 50 or 60 Hz, which is the same frequency as the AC electricity grid. High-frequency inverters operate at a much higher

Converting 60Hz to 50Hz: A Comprehensive Guide to Frequency

May 17, 2025 · The Ultimate Guide to Frequency Converters: Converting 60Hz to 50Hz In a globalized world, many electrical devices are designed to operate at specific frequencies,

What Happens if I Use 50Hz Equipment with 60Hz Supplies?

Jul 19, 2024 · In regions where 50Hz is the standard frequency, electrical devices and equipment are designed to operate optimally at this frequency. On the other hand, in regions where 60Hz

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

50hz appliances used on US 60hz shore power

Dec 28, 2018 · Trying to understand the dynamic of how electricity is delivered to a boat''s AC devices, when plugged into shore power . If my inverter is powerful enough to run a given

Operating 60Hz Electrical Appliances at 50Hz

Jun 10, 2008 · Potentially destructive testing of 115V appliances can lead to smoke, sparks, flame and can create an electrocution hazard. Cheap internal 115V 60Hz transformers in electronics

Running 50Hz appliances on 60Hz power system

If the appliance''s electric motor is designed for 60 Hz will therefore be rotate at 20% lower RPM at 50 Hz and reduce the fan torque by 40%. There is no risk of overloading the motor, but a

The difference between a high and low frequency inverter

High frequency inverters are compact and efficient, making them ideal for applications where space is limited, such as solar power systems and portable devices. Low frequency inverters

60 Hz home appliances on 50 Hz electricity

Oct 8, 2017 · If I get a washing machine designed to work on 220 V 60 Hz, can it run safely on a 220 V 50 Hz electricity source? The item is relatively new (the

6 FAQs about [Can the inverter high frequency be used with 50hz appliances ]

What is a high frequency inverter?

High frequency inverter: High frequency inverters use high-frequency switching technology to chop DC power at high frequency through high-frequency switching tubes (such as IGBT, MOSFET, etc.), and then convert high-frequency pulses into stable alternating current through high-frequency transformers and filter circuits.

What is the difference between low frequency and high frequency inverters?

In fact, low frequency inverters can operate at the peak power level which is up to 200% of their nominal power level for several seconds, while high-frequency inverters can operate at 150% power level for a small fraction of a second.

What internal frequency do inverters operate at?

What internal frequency the inverter circuits operate at – low frequency or high frequency (not to be confused with AC power output frequency which is a standard 50Hz for our inverters). Low-frequency inverters have the advantage over high-frequency inverters in two fields: peak power capacity, and reliability.

Are high-frequency inverters a good choice?

Due to the use of high-frequency switching technology, high-frequency inverters have the advantages of small size, lightweight, and high efficiency, but they also have the problem of relatively poor output waveform quality.

Are power frequency inverters good?

In contrast, power frequency inverters can maintain high efficiency and stability under heavy load or overload. Output waveform quality: The output waveform quality of power frequency inverters is usually better than that of high frequency inverters.

What are the advantages of high frequency inverters?

Volume and weight: Since high frequency inverters use high-frequency switching technology and compact circuit design, their size and weight are usually much smaller than power frequency inverters. This gives high frequency inverters significant advantages in mobile power supplies, aerospace, electric vehicles, and other fields.

Learn More

- Mexican High Frequency Inverter Company

- Macedonia high frequency inverter equipment

- 168kw high frequency inverter

- High frequency isolated energy storage inverter

- How many watts does a pure high frequency inverter have

- Inverter low frequency and high frequency

- High frequency inverter 2025

- High frequency pure sine wave inverter

- 1kW high frequency inverter power consumption

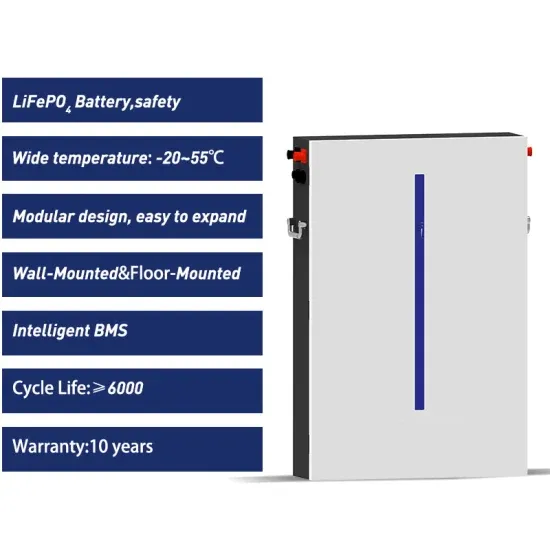

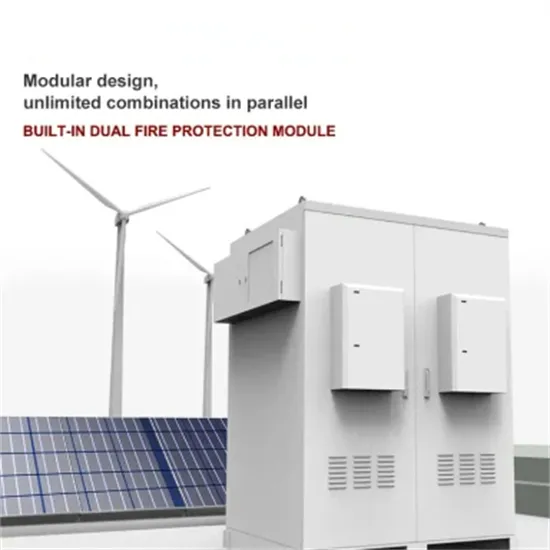

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.