What is the String Solar Inverter?

Apr 1, 2020 · String solar inverter is one of the three different kinds of solar inverters, where the other 2 kinds are Central solar inverter and micro solar inverter. In string solar inverter, there

Part 3: How to Design Grid-Connected Solar PV

Jul 24, 2012 · This is a the third installment in a three-part series on residential solar PV design. The goal is to provide a solid foundation for new system

Solar Optimizers & Optimized String Inverters

May 13, 2024 · When sourcing solar inverters for solar projects or business, you would often come across solar optimizers AND optimized string inverters.

What is the difference between MPPT input and

Apr 6, 2022 · 3) Accurate fault location: The inverter independently detects the voltage and current of each input channel, can sample the current and voltage

String Inverter: Advantages and Disadvantages

Nov 16, 2022 · During the inverter''s operation, the DC power received from each solar panel is combined and, at the same time, converted into AC power. The number of solar panels that

The PV panel configuration way of the string

Feb 26, 2024 · The string inverter is a key device used in solar power generation systems. It is responsible for converting the DC power generated by the solar

Exceeding Inverter Limits

Feb 2, 2020 · Do I have this layout correct/best? If yes, can I use 12 gauge wire for this? (it needed to travel about 40'' to the inverter) Thanks View attachment 186830 If the panels are 66

Advantages and Disadvantages of Different

Jul 11, 2023 · String Inverters – string inverters are similar to central inverters in terms of having a maximum input voltage of 1,000V. Before, string inverters

Photonik | String Voltage Calculator

Oct 13, 2023 · Solar String Voltage Calculator Why is calculating the string voltage so important? When designing a solar system using string solar inverters or solar charge controllers,

Schematic diagram of string photovoltaic inverter

May 24, 2024 · What is a string inverter for solar panels? ls connected together is referred to as a string. In this article,we''ll be focusing n string inverter (as opposed to microinverters). Each

Photonik | String Voltage Calculator

Oct 13, 2023 · The MPPT operating voltage range for most string inverters is between 80V and 600V, depending on the inverter make and model. The voltage range for Solar MPPT charge

How Does Input Voltage Affect a Grid-Tie Inverter?

Aug 29, 2019 · Just try to match the string voltage to the rated operating voltage of the inverter, you will have the highest efficiency, and the maximum voltage

Recommended Requirements for Inverter Application

In the PV system, the PV string configuration must meet the inverter configuration requirements for different inverters to achieve optimal energy yields. This configuration solution lists some

Explanation of String Inverters

Apr 11, 2024 · In string inverter systems, solar panels are wired in series. Then connected by a single string to a string inverter. String inverter combines all the direct current from each solar

Solar Inverter String Design Calculations

Oct 12, 2023 · Solar Inverter String Design Calculations The following article will help you calculate the maximum / minimum number of modules per series string when designing your

Solar Inverter String Design Calculations

Dec 11, 2023 · In each string, the connected solar panels should be within 4-20 modules. Since the best MPPT voltage of the phase inverter is around 630V (the best MPPT voltage of the

Solar Inverter String Design Calculations

Dec 11, 2023 · Solar Inverter String Design Calculations The following article will help you calculate the maximum/minimum number of modules per series string when designing your PV

Understanding inverter startup voltage.

Jun 4, 2021 · Meaning that each individual string has to be of a certain size to reach the inverter start up voltage separately. For example; inverter start up voltage 90v. So each string has to

6 FAQs about [What is the voltage of each string of the inverter ]

What is the operating voltage range for a string inverter?

The MPPT operating voltage range for most string inverters is between 80V and 600V, depending on the inverter make and model. The voltage range for Solar MPPT charge controllers is generally much lower and varies from 24V up to 250V. However, several high-voltage models are available which operate up to 600V.

How does a string solar inverter work?

All modern string solar inverters have one or more MPPTs (maximum power point trackers) to track the string voltage and lock onto the optimum voltage, which in turn produces the maximum power. Throughout the day, many variables will influence the string voltage, including; weather, shading and temperature.

What is the minimum string size of a PV inverter?

The minimum string size, then, is 15 modules. The maximum string size is the maximum number of PV modules that can be connected in series and maintain a voltage below the maximum allowed input voltage of the inverter. The Module Voc_max is calculated using the coldest temperature when the modules produce the highest expected voltage.

How does a solar inverter work?

This string positive and negative terminals “DC” will be connected to the string inverter input side. As the panels will be connected in series, the overall string DC voltage will be high (typically 200-850V) and the circulating current will be low (equal to one solar panel rated current).

How many solar panels should a single phase inverter have?

In each string, the connected solar panels should be within 4-20 modules. Since the best MPPT voltage of the phase inverter is around 630V (the best MPPT voltage of the single phase inverter is around 360V), the working efficiency of the inverter is the highest at this time.

How do you calculate a voltage rating for an inverter?

Simply divide the inverter’s maximum system voltage rating by the open circuit voltage (Voc) of the module used and you’re good. Well, that does get you in the ballpark, however, you could be at risk of over-sizing or under-sizing the number of modules in a string depending on where you are located in the world.

Learn More

- What is the maximum voltage of a 48v inverter

- Inverter string output voltage

- What is the voltage of a 60v inverter

- What is the best voltage for a power frequency inverter

- Muscat inverter output voltage

- Praia Voltage Inverter

- High frequency inverter post-stage voltage stabilization components

- What structure does the three-phase inverter in vsc use

- Inverter protection voltage range

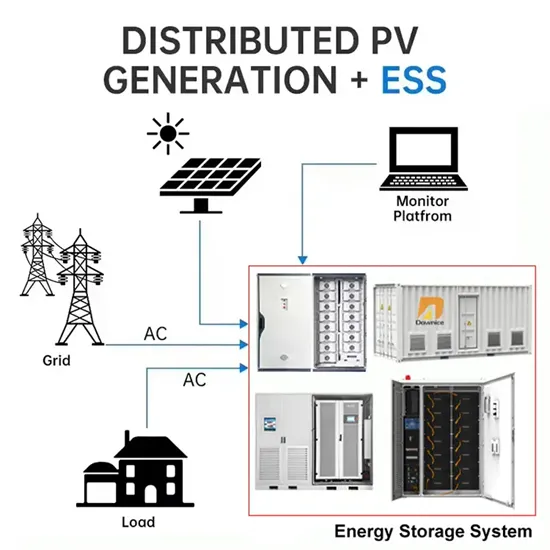

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.