Checklist for Choosing an Inverter

The inverter output voltage should comply to the standard voltage level and has to be within 228V to 252 V.For U.S, the accepted voltage level is 110V.The inverter output voltage needs to be

Application Note

Mar 20, 2024 · Setting the grid protection values is prohibited unless explicitly approved by the grid operator. This feature is offered to you as a convenience, and SolarEdge disclaims all

Photovoltaic inverter voltage protection principle

the two main goals of grid-connected PV inverters. To facilitate low-voltage ride-through (LVRT),it is imperative to ensure that inverter currents are sinusoidal and remain within pe

AC voltage value setting manual

Aug 30, 2022 · Before operating, please turn off AC switch, and turn on DC switch. If there are several inverters being co e (corresponding RS232 port on the bottom of inverter as Figure 3).

A system for inverter protection and real-time monitoring

Oct 29, 2015 · Voltage source inverters (VSI) include an L-C filter at the output stage thus, in case of an output short-circuit condition, the filter inductance limits the output current rising rate [3].

6KW Single Phase Hybrid Inverter SUN-6K-SG04LP1-EU-SM2

6KW Single Phase Hybrid Inverter SUN-6K-SG04LP1-EU-SM2 with IP65 Protection Degree Solar Inverter 6kw No reviews yet certified Anhui Minvic Import & Export Co., Ltd. 3 yrs

IGBT Inverter DC Industrial TIG/MMA Welding Machine TIG

Key attributes material / metal processed Stainless Steel, Carbon Steel, Aluminum warranty 1 Year motor type Stepper Motor rated duty cycle @40°c (tig) 60% protection grade Ip67

Inverter Protection and Ride-Through : RNWBL

Sep 22, 2022 · The inverter voltage control characteristic can be combined with a plant controller to provide Point of Interconnection (POI) voltage controls that

How to Read Solar Inverter Specifications

Nov 17, 2023 · Maximum Power Point Tracking or MPPT refers to the optimal voltage level at which the inverter can extract the most power from the solar panels. So, for efficient power

Solar grid tie inverter protection function introduction

May 20, 2022 · Grid-tied protection automatic recovery: After the grid-tied inverter stops supplying power to the grid due to grid failure, the grid-tied inverter should be able to automatically send

PH5900 TM Series (12-15KW) – Hybrid Solar

6 days ago · UsingDSP digital control,could afford wide grid voltage range, have a full range of protection features; to maximize the benefits at the same time,

Understanding Inverter Ratings and Specifications for Solar

6 days ago · Proper matching of the inverter''s input voltage range with the output voltage range of the solar panels is crucial to optimize system performance and prevent damage. Output

Reference Design for Reinforced Isolation Three-Phase

May 11, 2022 · Apart from isolated gate-drivers for IGBTs, the three-phase inverters include DC bus voltage sensing, inverter current sensing, IGBT protection (like over-temperature,

6 FAQs about [Inverter protection voltage range]

What are inverter voltage ratings?

Inverter voltage ratings are critical to ensure compatibility with your solar system and battery setup. Pay attention to these numbers. When selecting an inverter, understanding voltage ratings ensures proper system compatibility, efficiency, and longevity. Key ratings to focus on include rated voltage, maximum input voltage, and others.

What happens if an inverter reaches a safe range?

Inverters equipped with over- and under-voltage protection automatically monitor the input and output voltage levels. If the voltage deviates from the preset safe range, the inverter will either shut down or adjust its output to bring the voltage back within acceptable limits.

What is the maximum input voltage for a residential inverter?

Typically, residential inverters have a maximum input voltage between 500V and 1000V. Choosing one with a higher rating ensures greater flexibility and better performance in different weather conditions.

What are the input specifications of a solar inverter?

The input specifications of an inverter concern the DC power originating from the solar panels and how effectively the inverter can handle it. The maximum DC input voltage is all about the peak voltage the inverter can handle from the connected panels. The value resonates with the safety limit for the inverter.

How many MPPT inputs does an inverter have?

Most inverters come with two MPPT inputs, allowing them to track two different arrays with different voltage profiles. Minimum startup voltage is the lowest voltage at which an inverter will begin operation. The minimum startup voltage 4 tells you the lowest point the inverter needs to begin functioning.

What are inverter specifications?

Specifications provide the values of operating parameters for a given inverter. Common specifications are discussed below. Some or all of the specifications usually appear on the inverter data sheet. Maximum AC output power This is the maximum power the inverter can supply to a load on a steady basis at a specified output voltage.

Learn More

- Inverter adjustment voltage range

- Sungrow inverter unit voltage protection

- Inverter with protection voltage

- Does the inverter have low voltage protection

- Universal voltage range of inverter

- Inverter prompts low voltage protection

- 12v inverter protection voltage change

- Inverter rated phase voltage

- Ouagadougou voltage inverter

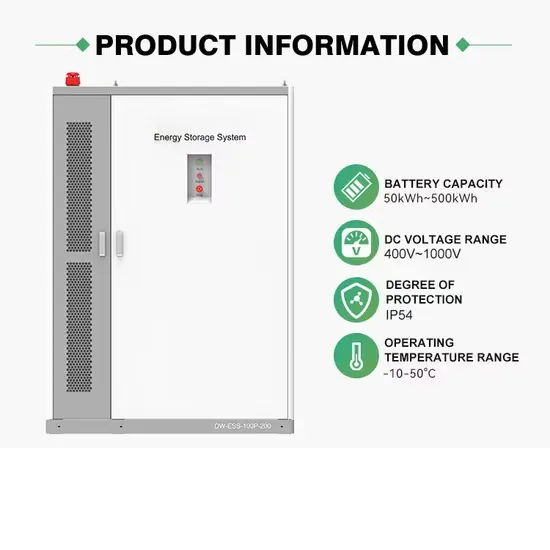

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.