Introduction to Three Level Inverter (TLI) Technology

Oct 29, 2018 · 4 is twice that of the phase voltage shown in Figure 3. A two level inverter is required to use two times the switching frequency of an NPC inverter in order to achieve the

HVDC Voltage Sourced Converters (VSC) and their

Mar 24, 2023 · This chapter introduces the basic characteristics of the theoretically proven voltage source converter (VSC) types, their basic concepts and working principles. It highlights the

Study and analysis of voltage source converter control stability for

Sep 1, 2021 · The three-phase VSC is controlled by two control loops: inner current control loop and outer voltage control loop as shown in Fig. 3. In such control, the inner current control loop

VOLTAGE SOURCE CONVERTER BASED HVDC

Nov 1, 2021 · The topology selection for the VSC-HVDC is based on the desired capabilities. Physical Structure The main function of the VSC-HVDC is to transmit constant DC power from

Design and implementation of a 3-phase, 2-Level

Jan 16, 2018 · ABSTRACT esign of a 2-level, 3-phase Voltage Source Converter (VSC) is explained. A 10kVA, 415V 3-pha e VSC has been designed, fabricated and tested in the labs

Three-Phase Battery Energy Storage System

May 14, 2019 · Figure 4 shows a three-phase battery energy storage system (BESS) comprising of Buck/Boost DC-DC converter and voltage source converter (VSC). A general description of

Design and implementation of a 3-phase, 2-Level

Jan 16, 2018 · ABSTRACT In this report, step by step design of a 2-level, 3-phase Voltage Source Converter (VSC) is explained. A 10kVA, 415V 3-phase VSC has been designed, fabricated

GFM_Inverter_documentation

Aug 1, 2022 · 1 Description This document presents a generic EMTP model for a three-phase aggregated grid-forming inverter (GFM inverter). It can be used for stability, fault, harmonic,

Generalised average modelling of grid-connected three

Jan 13, 2021 · Abstract: Based on the generalised averaging method, a comprehensive mathematical model for a three-phase grid-connected voltage source converter (VSC) with

Harmonic Analysis Of Svpwm Techniques For Three

Mar 8, 2022 · 2. THREE PHASE INVERTER The structure of a typical 3-phase power inverter is shown in Fig. 1, where VA, VB, VC are the voltages applied to the star-connected motor

Single-phase and Three-phase Two-level VSC Converters

Jun 28, 2019 · This chapter explains the principles of voltage source converters (VSCs), which have a two-level AC waveform and operate with single switching per cycle. Such topology

Lecture 23: Three-Phase Inverters

Feb 24, 2025 · However, most 3-phase loads are connected in wye or delta, placing constraints on the instantaneous voltages that can be applied to each branch of the load. For the wye

Converter Topologies in VSC-HVDC Systems-an overview

Mar 8, 2022 · Abstract— The converter topologies in VSC-HVDC system have an important role in the performance of the system. In this paper, an overview of converter topologies such as,

Three Phase VSI with 120° and 180° Conduction

Oct 27, 2024 · This results in reliable and safe operation of the inverter, at the cost of poor utilization of the switches capacity. Advantages of Three-Phase

NEW THREE-PHASE SYMMETRICAL MULTILEVEL

Jan 21, 2022 · In a three level inverter each phase leg generate the three voltage levels (Vdc/2, 0, –Vdc/2). Three-level inverter is similar to a conventional two-level inverter, but with clamping

NAPS_2020_Single_Phase_VSC.pdf

Aug 22, 2020 · The penetration of inverter-based renewable energy re-sources significantly increases recently and the control of inverter becomes a critical topic in the renewable energy

Comparison between two levels and multi-level (NPC and Cascad) inverters

Jan 1, 2022 · The structure of an H-bridge cascade-type three-level inverter arm is identical to that of a conventional one-phase full bridge inverter. However, the control technique is different

VSC-MMC STATION MODELS

Aug 1, 2022 · The active power is controlled by the phase-angle shift between the VSC and the ac system, while the reactive power is controlled by varying the VSC voltage magnitude [15].

Working Principle and Basic Control Strategy of the VSC

Aug 14, 2020 · In the VSC-HVDC grid, the converter is the core equipment for energy conversion and control between ac side and dc side. The voltage source converter (VSC) based on the

A Review of LCC-HVDC and VSC-HVDC Technologies

Jul 28, 2017 · For example, the 12-pulse converter can follow six single-phase two windings, three single phase three winding or two three-phase two windings configuration to suit specification

6 FAQs about [What structure does the three-phase inverter in vsc use ]

What is a three-phase voltage source inverter block?

The Three-Phase Voltage Source Inverter block implements a three-phase voltage source inverter that generates neutral voltage commands for a balanced three-phase load. Configure the voltage switching function for continuous vector modulation or inverter switch input signals.

What is voltage source inverter (VSC)?

(VSC) is an indispensable part of a variety of power electronic systems. It finds application in motor drives, power facto correcting equipment, grid integration of renewable energy sources etc. Among other types of inverters, Voltage Source Inverte (VSI) is more efficient, more robust and gives faster dynamic response. Due to t

How does a 3 phase inverter work?

However, most 3-phase loads are connected in wye or delta, placing constraints on the instantaneous voltages that can be applied to each branch of the load. For the wye connection, all the “negative” terminals of the inverter outputs are tied together, and for the detla connection, the inverter output terminals are cascaded in a ring.

What are the different types of inverters?

Some of the inverters are: A voltage source inverter (VSI) is an inverter that converts DC source voltage into an AC output voltage. It is also known as voltage -fed inverter, suitable for situations where the DC source has negligible or low impedance.

What is a voltage source inverter?

A voltage source inverter (VSI) is an inverter that converts DC source voltage into an AC output voltage. It is also known as voltage -fed inverter, suitable for situations where the DC source has negligible or low impedance. VSIs are commonly used in Variable-Frequency Drive (VFD) systems to control the speed of 3-phase motors.

How many conduction modes are there in a 3 phase inverter?

However in three-phase inverters , this voltage is distributed across three phases to create a balanced three-phase AC output . There are two primary conduction modes in both single-phase and three-phase inverters i.e.. 120-degree conduction mode and the 180-degree conduction mode.

Learn More

- What size inverter should I use for a 240A lithium battery

- What inverter to use for a 2 volt battery

- What battery to use for inverter

- What inverter should I use for 1kw solar panels

- What size grid-connected box should I use for a 150kw inverter

- What inverter to use for photovoltaic

- Burundi three-phase inverter

- What size inverter is suitable for lithium battery

- North Asia three-phase inverter manufacturer

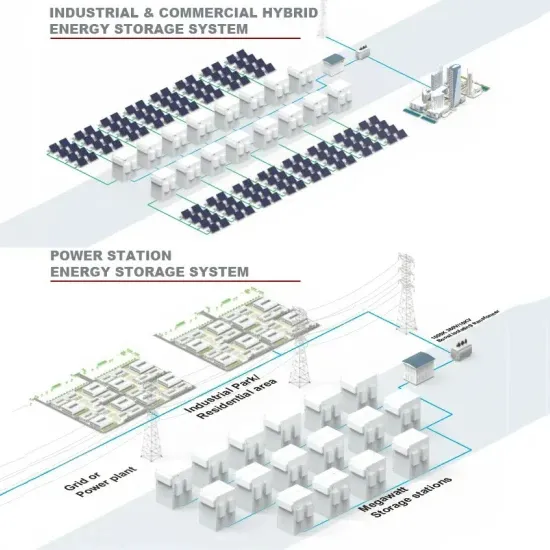

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

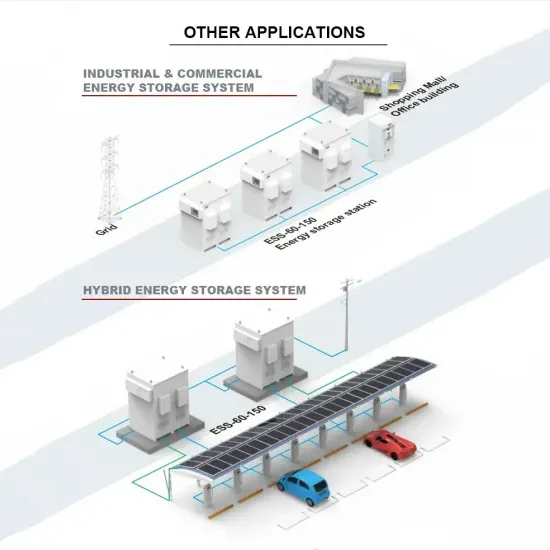

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.