PWM Dual Current Source Inverter Connected in Parallel

A dual current source inverter for an induction motor drive is presented in this paper. The dual inverter consists of two inverters connected in parallel and has single a dc power source. The

POWER ELECTRONICS DIGITAL NOTES

Jun 19, 2019 · UNIT - V: DC - AC CONVERTERS (INVERTERS): Inverters – Single phase inverter – Basic series inverter - operation and waveforms - Three phase inverters (120, 180

Design and Control of Dual Frequency Full-Bridge

Jun 27, 2022 · ABSTRACT This paper presents design and control aspects related to dual frequency full-bridge inverter are used for induction gear hardening application. Single dual

An improved modulation algorithm for the dual‐output

Aug 19, 2024 · The six-switch inverter has gained significant attention due to its ability to achieve dual AC voltage outputs with fewer semiconductor power devices. However, with existing

Study on Distributed Power Grid-Connected Dual

Oct 31, 2016 · 为提高分布式电源并网的效率,减小并网电流总的谐波畸变率,降低并网逆变器的开关损耗,研究了一 种新型双频并网逆变器,其中一部分工作在低频,采用电流滞环控制,

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · Power inverter is a device that converts electrical power from DC form to AC form using electronic circuits. It is typical application is to convert battery voltage into conventional

A double single-ended resonant inverter for low harmonic line frequency

May 5, 2025 · Therefore, this inverter is suitable for constant frequency and constant voltage applications such as electric motor drives, inductive heaters, uninterruptable power supplies

Research on Dual-Closed-Loop Control Strategy for LCL

Sep 24, 2024 · As power electronic devices continue to evolve, research on inverters has become increasingly sophisticated. Reference [1] proposed a deadbeat control method based on a

Design of Dual-Buck Inverter Control System Based on

Aug 14, 2023 · The dual buck circuit inverter under the half-cycle wave needs to enough power filter to ensure the ideal output waveform, which results in low frequency harmonic noise in the

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · ABSTRACT The High-Frequency Inverter is mainly used today in uninterruptible power supply systems, AC motor drives, induction heating and renewable energy source

Design and Control of Two-Inverter Dual Frequency

Dec 15, 2014 · Abstract—Dual frequency inverters are used for induction gear hardening. Two inverter topology for dual frequency operation is considered. Design and control aspects

Design of a Dual-Inverter Structure for a Point-to-Point

Mar 18, 2025 · The dual-inverter device integrates two synchronized full-bridge inverters to enable independent control of voltage and current components at different frequencies. Expanding

Accurate harmonic analysis of dual-frequency inverter

Apr 3, 2024 · In this paper, a double Fourier series-based method of harmonic analysis for the dual-frequency inverter (DF-inverter) is proposed, which can accurately calculate the

Analysis of five‐phase voltage source inverter with dual frequency

Jun 1, 2016 · Analyses of five-phase inverter load equation, error signal, system stability and states bounds are carried out. Further, the frequency domain analysis shows the noise

Analysis of five-phase voltage source inverter with dual frequency

Jun 8, 2016 · This study presents an analysis of five-phase voltage source inverter with dual frequency modulator to reduce baseband harmonics distortion. Analyses of five-phase inverter

Dual Output and Dual-Frequency Resonant Inverter-based

Feb 13, 2023 · Abstract A dual output dual-frequency (DODF) resonant converter-based AC-AC induction heating (IH) by using asymmetrical duty cycle (ADC) control is presented in this

Dual-Inverter Fed Induction Motor Drive using Optimal

Mar 8, 2022 · Abstract— This paper presents the synchronous optimal pulse width modulation (SOP) for control of medium–voltage induction motor drives using dual inverters at low

A Novel Inverter Control Strategy with Power

Jun 14, 2025 · Through the above mentioned control methods, GFM inverters can actively regulate AC voltage and frequency and eliminate the instabilities associated with PLL. Their

Voltage balancing for active power filter using dual-frequency

Jun 1, 2024 · In this paper, a switching control method integrated with voltage balancing feature is presented to manage operation of single-phase 5-level cascaded H-bridge (CHB) inverter as

Dual-Inverter Topology for Single-Phase Supplied Drive

Nov 4, 2021 · Abstract—Single-phase supplied variable speed drive (VSD) systems are widely used in industrial applications and typically feature a two-stage design with a power factor

Optimized Control of DAB in Two-Stage Single Phase Inverter

4 days ago · In order to reduce the intermediate dc-bus capacitance while maintaining high efficiency in the two-stage single-phase inverter system, an optimized double line-frequency

High Efficiency and Low Complexity Dual-Reference Voltage

Dec 22, 2023 · This study proposes a low complex and high efficient dual-reference voltage-based pulse width modulation (DRV-PWM) scheme for three-phase five-level hybrid active

A single-stage dual-source inverter using low-power

Jan 20, 2024 · These converters are powered by sources with different power and voltage levels, producing a fixed output of voltage and frequency 1, 2, 6, 7. In hybrid energy systems that take

High-frequency Inverter Design for a Wide Range of

Oct 29, 2023 · Abstract: This paper proposes a design methodology for a high-frequency resonant inverter module consisting of two inverters in parallel to deliver constant output power with

Double voltage vector model predictive control for grid

Nov 1, 2023 · In comparison to two-level inverter, multilevel inverter has many merits such as lower du/dt, better output waveform and lower switching frequency [4], [5], [6]. Therefore,

6 FAQs about [Dual voltage power frequency inverter]

What is a dual-source inverter?

This paper is an attempt to provide a dual-source inverter, an intelligent inverter topology that links two isolated DC sources to a single three-phase output through single-stage conversion. The converter is designed to be utilized in hybrid photovoltaic fuel cell systems, among other renewable energy applications.

Can an inverter operate at two different frequencies simultaneously?

To demonstrate and validate the suggested inverter's capability to operate at two distinct frequencies simultaneously for Z 1 and Z 2, the switching frequencies for Z 1 and Z 2 were chosen unevenly.

What is a dual-input dual-output inverter?

Reference 14 describes a dual-input dual-output inverter with nine switches, allowing each source to supply a separate load. In the topology presented in Ref. 15, the input sources cannot have random voltage or current levels. Two dual-input single-output three-phase inverters are discussed in Refs. 1, 2.

What is a dual-input single-output three-phase inverter?

Two dual-input single-output three-phase inverters are discussed in Refs. 1, 2. In the topology developed by Ref. 2, replacing the two inductors of the classic impedance source inverter with two transformers forms a new multi-port inverter. In this inverter, the DC-link voltage is a three-level signal with a specific switching frequency.

What are the efficiencies of the proposed inverter?

The efficiencies of the proposed inverter and those in previous works have been shown in Table 7. In this comparison, it should be considered that the proposed inverter is a single-stage, high voltage gain, microcontroller-based inverter which takes advantage from machine intelligence in its protection procedure.

What is a dual-stage multi-input inverter?

The topologies presented in Refs. 25, 26, 27, 28, 29, 30, 31, 32, 33 are dual-stage multi-input inverters. These topologies are unique in several ways, including their low number of semiconductors and absence of low-frequency transformers. These features make them well-suited for photovoltaic and grid-connected applications.

Learn More

- What is the best voltage for a power frequency inverter

- Inverter voltage of power frequency inverter

- Vanuatu power frequency isolation 120kw inverter

- Iraq three-phase power frequency inverter

- Kyrgyzstan power frequency isolation 150kw inverter

- Power frequency inverter connected to 220v to charge the battery

- Power frequency inverter dedicated to photovoltaic panels

- Chisinau off-grid power frequency inverter

- 5kva high frequency power inverter

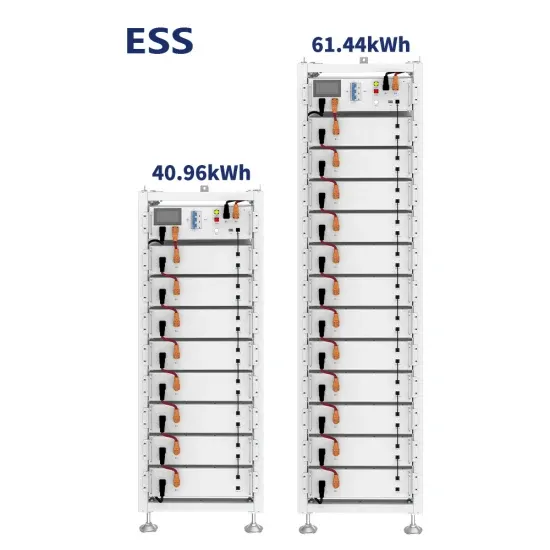

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.