Simple Voltage Balancing Control of Four-Level

Sep 30, 2024 · Particularly, the expression of the midpoint current, regarding the modulation index and phase current amplitude, is theoretically derived. This

Inverter fault diagnosis algorithm based on midpoint voltage

Jan 31, 2023 · This paper proposes a fault diagnosis method of three-phase inverter based on pulse transform. Firstly, the voltage between DC side midpoint and AC side midpoint is used to

Three-phase four-bridge-arm inverter energy storage

As shown in Figure 3, when the upper and lower switches of any phase bridge arm in the three-phase inverter bridge are turned on at the same time, the system works in the ST mode. the

Improved SVPWM modulation method for three-phase

Apr 25, 2023 · The disadvantage of this method is that the dc voltage utilization ratio is low and the software fault tolerance is dicult to realize. To solve these problems, an improved SVPWM

A Carrier-Based Pulse Width Modulation Algorithm for a

Nov 30, 2024 · In this paper, a carrier-based modulation algorithm is proposed for the traditional three-dimensional space vector modulation algorithm with the disadvantages of complicated

Inverter fault diagnosis algorithm based on midpoint voltage

Jan 31, 2023 · This paper proposes a fault diagnosis method of three-phase inverter based on pulse transform. Firstly, the voltage between DC side midpoint and AC side midpoin

Midpoint Voltage of Bridge Arm Based Fault Diagnosis

Aug 7, 2024 · Midpoint Voltage of Bridge Arm Based Fault Diagnosis Method of Inverter and Phase Winding for DSEM IEEE Transactions on Industrial Electronics ( IF7.5 ) Pub Date :

Switch Open-Circuit Fault Diagnosis Method Using Bridge

Jul 12, 2024 · Subsequently, the OCFD method is introduced, which exclusively depends on the integral value of the voltage at the midpoint of the primary-side switching bridge arm. Following

A unified SVPWM fault tolerant control algorithm for single

Apr 17, 2024 · To improve the reliability of Two-level three phase voltage source inverters, a uniform fault tolerant strategy based on space vector pulse width modulation is proposed for

Fast open-transistor fault diagnosis based on calculated bridge arm

Dec 8, 2016 · A novel fast open-transistor diagnosis approach for voltage-source inverters (VSI) based on calculated bridge arm pole-to-pole (PTP) voltages is proposed in thi

Three-phase four-bridge-arm inverter energy storage

Commonly used when the inverter needs to exchange energy with a low voltage grid, i.e. a four-wire grid or even a microgrid. This type of inverters can be classi ed into: Three-leg split

Midpoint Voltage of Bridge Arm Based Fault Diagnosis Method of Inverter

In order to solve this problem, this article proposes a fault diagnosis method of inverter and phase winding for doubly salient electromagnetic motor (DSEM) based on the midpoint voltage of

Open-Circuit, Current Sensor Fault Diagnosis of Three

Apr 30, 2024 · After that, fault diagnosis is achieved using the normalized detection variables of the ideal bridge arm voltage and the fit bridge arm voltage. Meanwhile, the open-circuit faults

The Control Technology Research of the Z-source Three

Dec 24, 2013 · The fourth bridge arm is individually controlled. Based on the advantages of the Z-source network and three-phase four-bridge arm inverter, this paper presents Z source three

Midpoint Voltage of Bridge Arm Based Fault Diagnosis

Aug 7, 2024 · Modulated PLPR-Based Predictive Control With Noise Suppression for LC-Filtered Voltage Source Inverters Performance Analysis of Rapid Capacitor Charging System Based

A unified SVPWM fault tolerant control algorithm for single

Apr 17, 2024 · The reconstructed topologies of inverters with different bridge arm faults are different, which makes the basic voltage vector phase of each reconstructed topology

The Control Technology Research of the Z-source Three

Dec 24, 2013 · This paper presents a Z-source three-phase four-leg inverter which combines a Z-source network with three-phase four-leg inverter. The circuit uses simple SPWM modulation

Open-Circuit, Current Sensor Fault Diagnosis of Three

Apr 30, 2024 · First, the ideal bridge arm midpoint voltage and the actual bridge arm midpoint voltage are derived, and empirical wavelets are used for adaptive banding of the bridge arm

Characteristics of Common-Mode Voltage Offset in Small

Dec 7, 2023 · The diagnostic methods based on bridge arm voltages proposed in references [17, 18] achieved fast diagnosis, high reliability, and speed by utilizing the characteristics of bridge

Three-Level Midpoint Potential Balance and Harmonic

Three-Level Midpoint Potential Balance and Harmonic Suppression Strategy Under Low Carrier Ratio Abstract: - An improved virtual space vector modulation method is proposed to address

Midpoint Voltage of Bridge Arm Based Fault Diagnosis Method of Inverter

Aug 7, 2024 · In order to solve this problem, this article proposes a fault diagnosis method of inverter and phase winding for doubly salient electromagnetic motor (DSEM) based on the

Research on Neutral Point Voltage Balancing in Single-Phase

Jan 28, 2025 · Figure 4 shows the midpoint voltage uab, output voltage uo, and output current io in the bridge arm under the newly proposed H-SVPWM. Through uab, the inverter operates in

Mid-point potential balancing in three-level inverters

vel inverter leads to low harmonics in the output voltage, causing voltage distortion and seriously reducing the power quality. The unbalanced mid-point voltage also puts more voltage strain on

Switch Open-Circuit Fault Diagnosis Method Using Bridge Arm Midpoint

Oct 1, 2024 · IEEE Transactions on Power Electronics, volume 39, issue 10, pages 13795-13807 Switch Open-Circuit Fault Diagnosis Method Using Bridge Arm Midpoint Voltage Integral for

6 FAQs about [Inverter bridge arm midpoint voltage]

Why are reconstructed topologies of inverters with different bridge arm faults different?

The reconstructed topologies of inverters with different bridge arm faults are different, which makes the basic voltage vector phase of each reconstructed topology inconsistent, resulting in different calculations.

What are two-level three-phase voltage source inverters?

Two-level three-phase voltage source inverters often apply two control methods: sinusoidal pulse width modulation (SPWM) and space vector pulse width modulation (SVPWM). The SVPWM owns a higher utilization rate of DC voltage and does not require triangular carriers, allowing it to be broadly employed 4, 5, 6.

How difficult is SVPWM under different bridge arm faults?

The difficulty and complexity of SVPWM under different bridge arm faults is considered in Refs. 15, 16, and SVPWM calculation is optimized. According to the “Volt-Second” relation, the equivalence of the calculation formula describing basic voltage vector action time with different reconfiguration topologies is simply narrated in Ref. 15.

How to improve reliability of two-level three phase voltage source inverters?

Scientific Reports 14, Article number: 8819 (2024) Cite this article To improve the reliability of Two-level three phase voltage source inverters, a uniform fault tolerant strategy based on space vector pulse width modulation is proposed for different leg faults.

Are two-level three-phase voltage source inverters fault-tolerant?

The fault-tolerant control of two-level three-phase voltage source inverters has been extensively studied 1, 2, 3, including two reconstruction aspects: hardware topology and software control strategy. Various fault-tolerant reconfiguration topologies of three-phase voltage source inverters have been summarized in Refs. 1, 2, 3.

Can a bridge arm fault be rotated through coordinate transformation?

Since the SVPWM of reconstructing topology in case of a phase A bridge arm fault is the simplest 18, 19, 20, the voltage vectors of phase B and C bridge arm faults in Fig. 3 b,c can be rotated through coordinate transformation, to be consistent with Fig. 3 a.

Learn More

- Three-phase bridge inverter input voltage

- 180 degree voltage inverter replacement

- Synchronous voltage function of inverter

- How much does a 1000w voltage inverter cost

- 12v to 500 high voltage inverter production

- Muscat inverter output voltage

- Inverter can control voltage

- 800W inverter input voltage

- High voltage inverter overall equipment

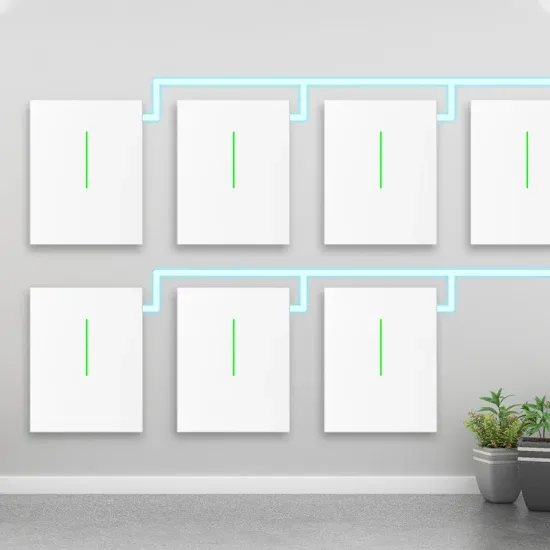

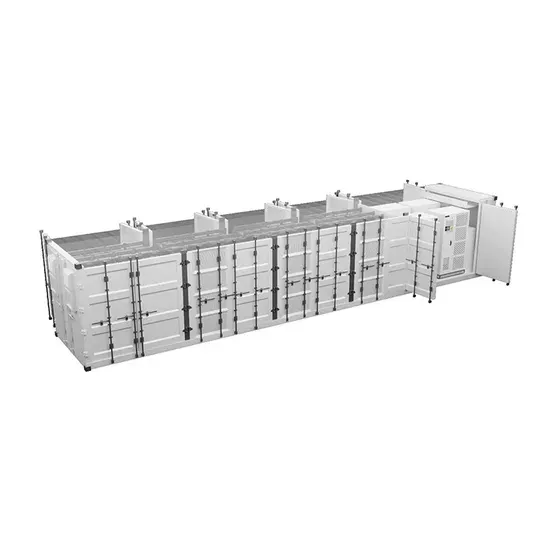

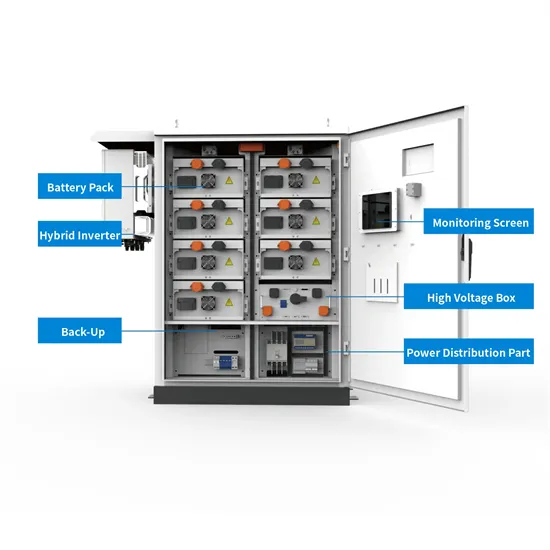

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.