Three Phase Inverter Simulation using Sinusoidal PWM

Nov 30, 2020 · ABSTRACT: This paper presents the simulation of three phase voltage switching inverter in MATLAB/Simulink using Sinusoidal Pulse Width Modulation (SPWM) scheme. The

MOSFET BASED THREE PHASE BRIDGE INVERTER FOR

Dec 10, 2024 · Three phase bridge inverter consists of six switches and six diodes, here MOSFET has been chosen as the switch. The main function of the three phase bridge inverter is to

120° Mode Inverter – Circuit Diagram, Operation

Sep 8, 2020 · This article explains the 120° mode inverter with the help of relevant circuit diagrams, output waveforms. Formulas for phase and line voltage &

Next-Generation SiC/GaN Three-Phase Variable-Speed

May 5, 2021 · First, a new phase-modular buck-boost inverter concept (Y-inverter) is introduced and subsequently condensed into a three-phase current DC-link DC/AC converter that

Three-Phase Inverter Reference Design Using Gate

Dec 6, 2017 · This unique dead time insertion protects the three-phase inverter against shoot-through due to overlap of the input PWM signal. System reliability is improved by protecting

Some Aspects on 3-Phase Bridge Inverter (180 Degree

May 20, 2019 · In this paper we highlight the Simulink program in MATLAB for 3 phase bridge inverter for 180 degree mode. Frequency and output voltage can be changed using slider

Three-Phase Voltage Source Inverter

Feb 13, 2024 · 1 Overview This model shows a three-phase voltage source inverter (VSI). The VSI is an inverter circuit which cre-ates AC current and voltage from a DC voltage source.

Three-Phase Modular Cascaded H-Bridge Multilevel

Nov 19, 2012 · Abstract— A three-phase modular cascaded H-bridge multilevel inverter for a grid-connected photovoltaic (PV) system is presented in this paper. To maximize the solar energy

[Solved] Three Phase Bridge Inverters MCQ [Free PDF]

Aug 11, 2025 · Three Phase Bridge Inverters Question 1: In the standard three-phase voltage source inverter topology, which of the two states out of the eight valid switching states

3 Phase Inverter Circuit Diagram Using Mosfet

Sep 8, 2017 · A three phase inverter consists of three half-bridge inverter circuits connected in a series. Each half-bridge inverter is composed of two MOSFETs

Analysis of Three-Phase Voltage-Source Inverters

Mar 21, 2020 · The inverter is not only a three-phase bridge made by three half-bridge legs but also needs other elements for its correct operation. For example, the stability of the voltage

OPERATION OVERVIEW OF THREE PHASE INVERTER

Jul 24, 2017 · In this paper we are going to represents the basic overview of three phase inverter with conduction mode of 120°, 150° AND 180°. The Three phase inverter working and output

Three-Phase Voltage Source Inverter: Design and

Dec 20, 2024 · A three-phase voltage source inverter consists of three half-bridge switches, each of which generates a sinusoidal voltage waveform for each phase. The voltage waveforms are

DESIGN AND IMPLEMENTATION OF THREE PHASE

Apr 21, 2019 · Abstract This paper describes the design and implementation of three-phase inverter. Generally inverters are used in high power applications as industrial based induction

DESIGN AND IMPLEMENTATION OF THREE PHASE

Apr 21, 2019 · s voltage source inverters (VSI) and the other is current source inverter (CSI). The inverter with a DC source of small negligible impedance, i.e. there is a stiff DC voltage source

MOSFET BASED THREE PHASE BRIDGE INVERTER FOR

Dec 10, 2024 · The input voltage, output voltage, frequency, and overall power handling depend on the inverter design. Either current fed or voltage fed inverters is used to control the power,

Design a Single Phase Inverter and a Three Phase

A three phase bridge Inverter is a device which converts DC power input from a battery or from a rectifier into three phase AC output. It uses a minimum of six MOSFET transistors as shown in

Output common mode voltage of a newly combined three-phase full-bridge

May 30, 2022 · A topology of the combined three-phase full-bridge duplex inverter is shown in Fig. 1. The main circuit of the inverter consists of an input supporting capacitor, two three-phase full

Design of Sinusoidal Pulse Width Modulation 3 Phase

Jul 31, 2020 · The output of the inverter is direct current, so an inverter becomes a critical component for the flow of electricity from solar modules to storage battery, loads and grids. A

Analysis & Hardware Implementation Of Three-Phase

Mar 8, 2022 · For example, PWM-based three-phase voltage source inverters (VSI) convert DC power to AC power with variable voltage magnitude and variable frequency. This paper

Three Phase Bridge Inverter

It is crucial to note that freewheeling diodes play a crucial role in three-phase inverters with RL loads. According to Figure 23, the current in each inverter arm is delayed to reach its basic

What is a Three-Phase Inverter? | inverter

Sep 17, 2024 · Modular design is a key direction for future three-phase inverter design. By dividing inverters into multiple independent modular units, quick installation, maintenance, and

6 FAQs about [Three-phase bridge inverter input voltage]

What is a three phase bridge inverter?

This article outlines the definition and working principle of three phase bridge inverter. 180 degree conduction mode of operation, formula for phase & line voltages of three phase inverter is also explained in this article. A three phase bridge inverter is a device which converts DC power input into three phase AC output.

Can an inverter feed a three phase motor?

Therefore an inverter feeding a three phase motor must be capable of providing a variable voltage, variable frequency supply. The required voltage control can be obtained either external to the inverter or within it (Fig. 3.91).

What is a three phase inverter modulation scheme?

The standard three-phase inverter modulation scheme. The input dc is usually obtained from a single-phase or three phase utility power supply through a diode-bridge rectifier and LC or C filter. The inverter has eight switch states given in Table 4.1. As explained violating the KVL. Thus the nature of the two switches in the same leg is

What is a three-phase inverter?

Apart from isolated gate-drivers for IGBTs, the three-phase inverters include DC bus voltage sensing, inverter current sensing, and IGBT protection (like overtemperature, overload, ground fault, and so on). There are many end applications such as HVAC, solar pumps, and appliances where cost is major concern without compromising the performance.

What is a reference design for a 3 phase inverter?

This reference design reduces system cost and enables a compact design for a reinforced, isolated, 10-kW, three-phase inverter. A lower system cost and compact form factor is achieved by using a dual gate driver in a single package and bootstrap configuration to generate floating voltages for the gate drive power supply.

What is PWM technique in a 3 phase full-bridge inverter?

States of Three-phase Full-Bridge Inverter for 1800Conduction2.1 SPWM TechniqueIn Pulse Width Modulation (PWM) technique by modulating pulse dura ion and by modulating the Duty cycle we can generate a constant amplitude pulse. In this PWM technique it requires both reference and the carrier signals.With low frequency is taken as

Learn More

- 800W inverter input voltage

- Three-phase bridge inverter MOSFET

- Three-phase inverter DC side voltage

- Solar inverter input voltage

- Relationship between inverter input voltage and battery voltage

- Inverter input voltage upper limit

- Inverter capable of adjusting input voltage

- Inverter bridge arm midpoint voltage

- Boosting the voltage with an inverter

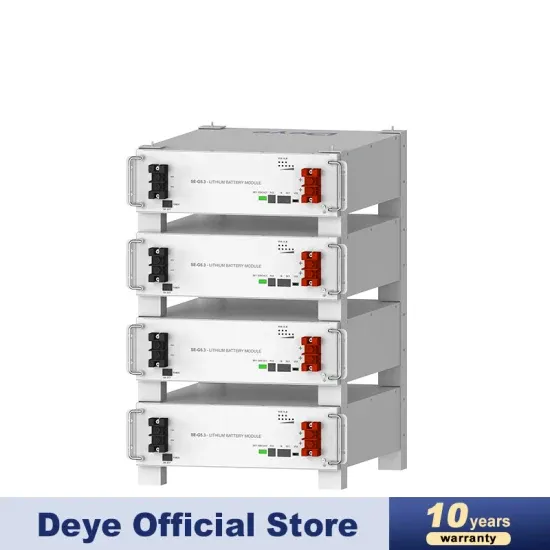

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

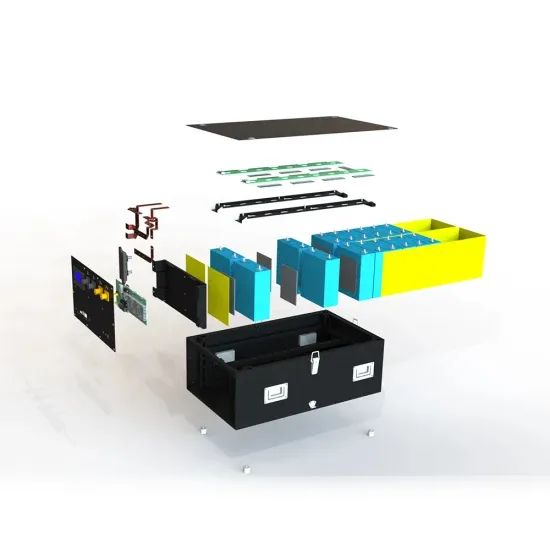

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.