Hybrid inverter 5.5KW 48v MPPT 90A/450V REVO

Buy 5.5KW REVO-E 450V hybrid inverter Buy the 5.5KW 48v hybrid inverter It is fast, safe and comfortable thanks to Wccsolar, plus the 5.5KW 48v hybrid inverter It has an official Wccsolar

Overview of power inverter topologies and control structures

Feb 1, 2014 · In grid-connected photovoltaic systems, a key consideration in the design and operation of inverters is how to achieve high efficiency with power output for different power

MoDel sPeCiFiCations oF inVerter

Jun 9, 2016 · MoDel sPeCiFiCations oF inVerter (As per MNRE Specifications) As SPV array produce direct current electricity, it is necessary to convert this direct current into alternating

Components and Functions of Low-Voltage Inverters in

Aug 30, 2024 · Learn about the core components and key functions of low-voltage inverters and how to improve industrial automation efficiency through speed control, energy saving and

Decoding Inverter Parameters (Part Ⅱ)

Feb 28, 2025 · In the previous lecture, we discussed key parameters such as the maximum input current, maximum short-circuit current, and rated input voltage of inverters. In this session, we

An eleven level single source switched capacitor boost inverter

2 days ago · The proposed structure, which consists of a single voltage source, 10 power electronic switches, 3 capacitors, and one diode, generates an 11-level stepped voltage

STRING INVERTER GENERATION 3 INVERTER

Mar 11, 2025 · The string inverter will take the DC energy from your full solar array to a single source and convert it into usable AC for your home. When paired with a GivEnergy battery

Design of an improved PWM inverter using PI controller

Jan 13, 2016 · The inverter is capable of producing more than 300V output-voltage levels from the 200 DC supply voltage. A digital proportional–integral current-control algorithm was

A review on topology and control strategies of high-power inverters

Feb 15, 2025 · Authors in [37] have developed a novel five-level common ground type (5L-CGT) transformer-less inverter topology with double voltage boosting, employing eight switches and

Voltage Source Inverters Control using PWM/SVPWM

Feb 13, 2014 · In this method, a fixed dc input voltage is given to the inverter and a controlled ac output voltage is obtained by adjusting the on and off periods of the inverter components.

Voltage Control Methods of Inverter – PWM

Feb 12, 2022 · The voltage control is primarily achieved by varying the firing angle of the ac voltage controller that feeds the ac load. In this method, there is a

Integrated Zeta–Ćuk-Based Single-Phase DC/AC Inverter for

Aug 17, 2025 · This work proposes a novel Integrated Zeta–Ćuk Inverter (IZCI), derived from combining the Zeta and Ćuk DC/DC converter structures. In addition, the proposed topology

REGULATING VOLTAGE: RECOMMENDATIONS FOR

Jan 12, 2025 · The new smart inverters are designed to allow customer-sited generation to act more in concert with the existing grid, with key features making these devices more grid

New Technology Self-Adjusting Input Voltage Inverter Low

Jul 8, 2025 · DC-AC Isolation Board: It uses the latest DC/AC inverter technology, with electrically isolated Input and Output for reliable isolation. Effortless installation: With its compact size and

The 6 Best Solar Energy Micro-Inverters of 2025:

Aug 18, 2025 · Boost your solar panel efficiency with 2025''s top micro-inverters, offering cutting-edge features and unparalleled performance. But which one

Inverter Specifications and Data Sheet

Aug 30, 2023 · Abstract: This article presents a wide input voltage range switched-capacitor multilevel inverter based on an adjustable number of output levels. Through different

Two-Mode Controlled Single/Dual-Input DC-AC Inverter

Jul 27, 2025 · By combining the two working modes, the proposed inverter achieves uniform distribution of duty ratio under single/dual-input with a wide range of input voltage, and thereby

Power Hardware-in-the-Loop Smart Inverter Testing

May 31, 2024 · The Saturation Limiter avoids user input errors that exceed the amplifier and inverter voltage limits. The voltage saturates at 160 Vrms L-N. Therefore, the voltage can

How Inverter Driven Compressors Work | A Guide for HVAC

Jun 26, 2025 · As HVAC contractors, understanding how inverter driven compressors work is essential for troubleshooting, maintenance, and explaining system benefits to your clients.

What is New Technology Self-Adjusting Input Voltage Inverter

What is New Technology Self-Adjusting Input Voltage Inverter Low No-Load Consumption and Heavy Duty Inverter, Volker pure sine wave inverter manufacturers & suppliers on Video

6 FAQs about [Inverter capable of adjusting input voltage]

Are voltage source type inverters easier to control?

Voltage source type inverters are easier to control than current source type inverters. It is easier to obtain a regulated voltage than a regulated current, and voltage source type inverters can directly adjust the voltage applied to a load by varying the conduction ratio (i.e., the pulse width of a PWM signal).

What is the amplitude range of a DC inverter?

The amplitude can vary from 10% to 20%, and the modification from low to high is not limited; just reduce the PWM duty cycle. Therefore, the input DC voltage fluctuation range of the inverter is -15% to 20%. As long as the voltage of the device allows, there is no restriction.

What is a voltage source type inverter?

Voltage source type inverters control the output voltage. A large-value capacitor is placed on the input DC line of the inverter in parallel. And the inverter acts as a voltage source. The inverter output needs to have characteristics of a current source. In the case of low impedance load, series reactors are needed for each phase.

What is an example of a power inverter?

Common examples are refrigerators, air-conditioning units, and pumps. AC output voltage This value indicates to which utility voltages the inverter can connect. For inverters designed for residential use, the output voltage is 120 V or 240 V at 60 Hz for North America. It is 230 V at 50 Hz for many other countries.

How do you classify an inverter based on its power output?

Using the CEC efficiency, the input power to the inverter must be PIN=POUT/CEC Efficiency=3,300 W/0.945=3,492 W Inverters can be classed according to their power output. The following information is not set in stone, but it gives you an idea of the classifications and general power ranges associated with them.

What is the output terminal of an inverter?

Output terminal: The output terminal of the inverter provides the converted AC power output and is connected to the corresponding load equipment, such as home appliances, motors, etc. The output usually includes an output connector and output protection circuitry. The inverter operates using a similar principle as a switching power supply.

Learn More

- Relationship between inverter input voltage and battery voltage

- Inverter input voltage upper limit

- 800W inverter input voltage

- 27V inverter input voltage

- Three-phase bridge inverter input voltage

- 12v inverter protection voltage change

- Inverter voltage and current reverse

- Dual voltage power frequency inverter

- Inverter charging voltage is low

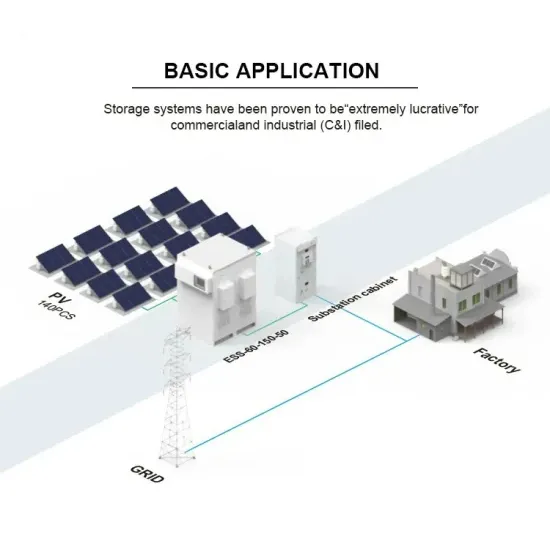

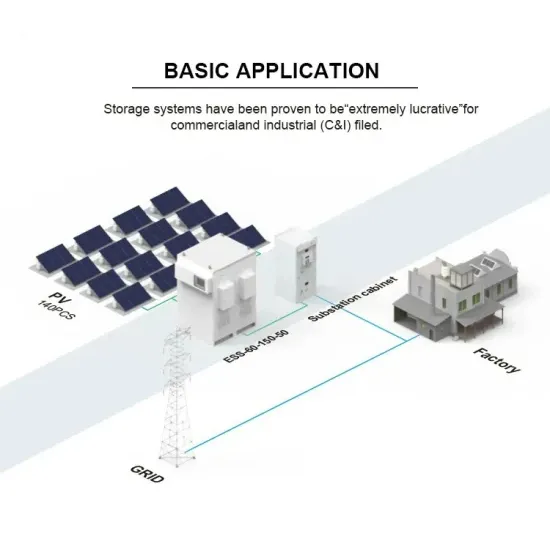

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

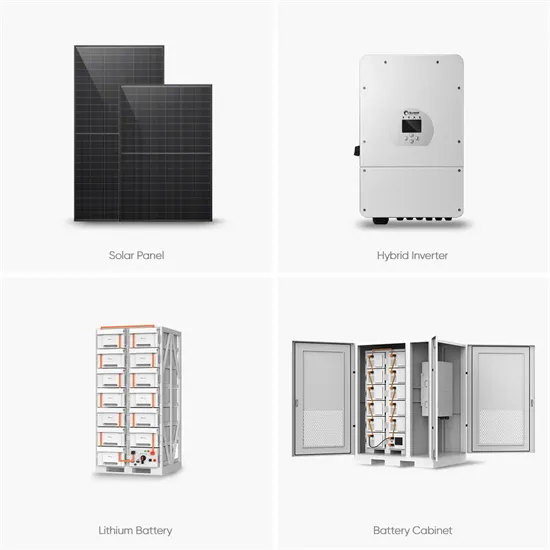

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.