DC/DC converter 250V to 27V, 999W • DWE

Jul 28, 2025 · The MW1000-DD27-P is a DC/DC converter that converts a DC voltage from 250V to 27V DC voltage and can supply a DC current of up to 37A. Converter from 250 to 27 Volt

1pc Boost Module 12V to 27V DC-DC Booster 9V-20V to 27V

Jul 11, 2025 · 1pc Boost Module 12V to 27V DC-DC Booster 9V-20V to 27V Power Converter Inverter car Inverter (12V to 27V 3A) : Amazon.ca: Tools & Home Improvement

Elevate Your Power: Step Up Power Modules for Voltage

Power up your DIY projects with our Step Up Power Modules. Whether you''re crafting energy-efficient devices or need a specific voltage level, these modules ensure efficient power

USB Input Voltage 5-27V Output Voltage 1-24V 3A Converter

USB Input Voltage 5-27V Output Voltage 1-24V 3A CV CC Converter Liquid-crystal Display DC-DC Adjustable Step Down Module. Customized support for various needs.| Alibaba

Voltronic inverter only charging to 27.6V

Hi, I have a Voltronic 24V 3kVA 3kW PWM inverter. Regardless of charging settings the bulk charge levels off at around 27.6V it should go up the set level, normally around 28 or 29V.

600W GaN-Based Single-Phase Cycloconverter

Apr 30, 2025 · In this design, the MPP deviation is defined as 1%, this means that > 99% of the maximum possible power is delivered to the inverter input. PV panels from several top

Power Supply Inverter Converter 12V to 27V Module 1-20A

Voltage Conversion & Regulation: Converts 12V DC input to a regulated 27V DC output, supporting current ranges from 1A to 20A. Designed to stabilize power delivery for sensitive

What happens when PV voltage is lower than MPPT Range?

Dec 30, 2020 · if i connect 2 40v panels in series to a hybrid inverter when the "MPPT Range" is 120~450V what happens? Do i need to hit 120v to even work, or is just an optimal zone? This

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The input AC Voltage Sensing is required in inverters for changing to Mains mode through relay operation when A/C mains fall in the designated voltage level. Further

Understanding Inverter Input And Output: What

3 days ago · Input Current: determines the amount of electric current required by the inverter based on the load and input voltage. Input Stability: if the input

1000W/ 1500W Off-Grid Solar Inverter

1 day ago · 1000W/ 1500W Off-Grid Solar Inverter Features: Pure sine wave solar inverter 40A MPPT Solar Charge Controller PV Input range 20V-150V (1000W model), 30-150V (1500W

4000W Blue Pure Sine Wave Power Inverter, DC 24V to AC

Choose according to the voltage standards of your region. Provides real-time monitoring of input battery voltage and output device voltage. Suitable for precision instruments, all kinds of

4000W Blue Pure Sine Wave Power Inverter, DC 24V to AC

Pure sine wave 4000 watts output DC Input Voltage: 23V-27V Intelligent LED display High-speed cooling fan with intelligent temperature regulation Remote control with a 15-meter range

AC-DC BATTERY CHARGER

May 8, 2014 · Step 1 After selecting the output voltage and frequency, press the setting button for 5 seconds and the inverter will send out a "Beep" sound. The button can be released and you

Interpreting inverter datasheet and main parameters | AE 868

At the same time, PV array voltage should operate within the input voltage range on the inverter to ensure that the inverter functions properly. Aside from the operating voltage range, another

Solar Inverter Specifications

Apr 3, 2025 · Where the DC input current exceeds an MPPT rating, jumpers can be used to allow a single MPPT to intake additional DC current up to 26 A I / 34 A I. Cellular connectivity

Understanding inverter voltage

Jan 10, 2024 · Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function

Inverter Voltage Calculator, Formula, Inverter Voltage

3 days ago · The output voltage of an inverter is determined by the DC input voltage and the modulation index. The modulation index represents the ratio of the inverter''s AC output

6 FAQs about [27V inverter input voltage]

What is the output voltage of an inverter?

It describes the output voltage of an inverter, which converts direct current (DC) from sources like batteries or solar panels into alternating current (AC). The output voltage of an inverter is determined by the DC input voltage and the modulation index.

What are the parameters of a PV inverter?

Aside from the operating voltage range, another main parameter is the start-up voltage. It is the lowest acceptable voltage that is needed for the inverter to kick on. Each inverter has a minimum input voltage value that cannot trigger the inverter to operate if the PV voltage is lower than what is listed in the specification sheet.

What is the output voltage of a grid-tie inverter?

For inverters designed for residential use, the output voltage is 120 V or 240 V at 60 Hz for North America. It is 230 V at 50 Hz for many other countries. Peak Efficiency The peak efficiency is the highest efficiency that the inverter can achieve. Most grid-tie inverters have peak efficiencies above 90%.

What voltage is a 12V inverter?

Inverters come in various configurations, each designed for specific power systems. Common rated input voltages include 12V, 24V, and 48V. The choice depends on the application, the size of the power system, and the available power source. A 12V inverter is commonly used for smaller applications, such as in vehicles or small off-grid setups.

What is an example of a power inverter?

Common examples are refrigerators, air-conditioning units, and pumps. AC output voltage This value indicates to which utility voltages the inverter can connect. For inverters designed for residential use, the output voltage is 120 V or 240 V at 60 Hz for North America. It is 230 V at 50 Hz for many other countries.

What are inverter specifications?

Specifications provide the values of operating parameters for a given inverter. Common specifications are discussed below. Some or all of the specifications usually appear on the inverter data sheet. Maximum AC output power This is the maximum power the inverter can supply to a load on a steady basis at a specified output voltage.

Learn More

- Relationship between inverter input voltage and battery voltage

- 800W inverter input voltage

- Solar inverter input voltage

- Inverter input voltage suddenly decreases

- Inverter capable of adjusting input voltage

- Is the inverter output voltage 233v normal

- The inverter output high voltage drops instantly

- High frequency inverter capacitor and resistor voltage reduction

- Morocco high voltage energy storage inverter manufacturer

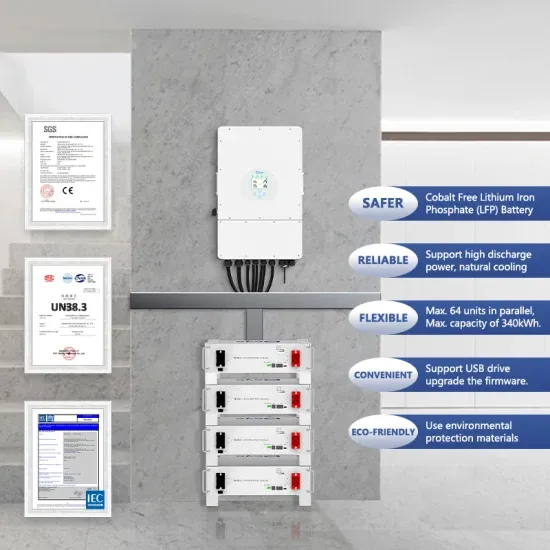

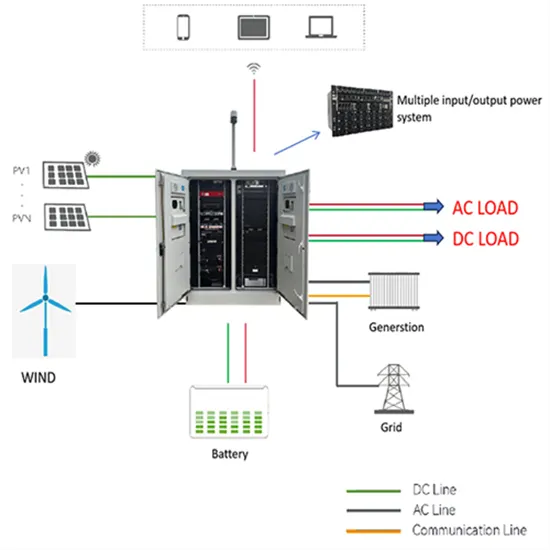

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.