Demystifying high-voltage power electronics for solar

Apr 1, 2023 · In all inverter configurations, the DC/DC stage uses high switching frequencies. However, the rail or DC link voltage could vary from as low as 200V to greater than 1kV

Using Huawei SUN2000 inverters with high DC/AC ratios

Jan 14, 2025 · Using Huawei SUN2000 inverters with high DC/AC ratios When the total Watt-peak (Wp) power of the solar modules exceed the nominal AC power rating of the connected solar

Inverter Current Calculator, Formula, Inverter Calculation

6 days ago · Inverter Current Formula: Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the

Low-voltage VS High-voltage Inverters: What''s the Difference

Inverter technology serves as the backbone of modern power conversion systems, facilitating the seamless transformation of DC to AC electricity. The distinction between low-voltage (LV) and

DC to AC Power Conversion Explained: Your Guide to Inverters

Jul 28, 2025 · Note: High-quality inverters with MPPT technology can significantly improve the performance of renewable energy systems, reducing energy losses and increasing overall

High Voltage Inverter: Unlocking the Potential of High

Aug 17, 2025 · Generally, a high voltage inverter is a type of inverter voltage that works by converting direct current (DC) into alternating current (AC) at high voltage. This high-voltage

Solar panel inverters & costs: the expert guide

Dec 14, 2023 · Solar panel inverters play a crucial role in any solar panel system, ensuring that the energy harvested from the sun is usable within your home.

Inverter reporting DC voltage too high

Aug 6, 2022 · , Inverter reporting DC voltage too high, Solar PV Forum | Solar Panels Forum, ElectriciansForums Est.2006 | Free Electrical Advice Forum and page_number.

High-efficiency DC/AC inverter, High-efficiency inverter

Power: 15,000 W - 50,000 W. the hybrid inverter range, the EQUINOX2 HT+ can be adapted to suit a wider range of scenarios and possibilities in more industrial settings. The power rating of

Power Inverters: What Are They & How Do They

Dec 17, 2019 · Key learnings: Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for

An advanced guide to Understanding DC to AC inverters

Apr 4, 2024 · Additionally, DC can also be stored in batteries and capacitors. DISADVANTAGES OF DC The major disadvantage of direct current is the commutation problem which means it''s

Efficiency of Inverter: Calculation & Equation

Mar 4, 2023 · The efficiency of an inverter refers to the amount of AC output power it provides for a given DC input. This normally falls between 85 and 95

High-voltage VS Low-voltage Inverters: What''s the difference?

Jul 31, 2025 · Conclusion Choosing between a high-voltage and low-voltage inverter isn''t about which one is better overall—it''s about what''s better for your specific situation. Small, mobile, or

6 FAQs about [How much is the inverter DC high voltage ]

Where can I find a high-voltage DC/AC inverter?

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data. Find your high-voltage dc/ac inverter easily amongst the 22 products from the leading brands (VEICHI, ABSOPULSE Electronics, Victron Energy,) on DirectIndustry, the industry specialist for your professional purchases.

How does a high frequency power inverter work?

The high-voltage inverter converts direct current (DC) from the batteries or generator to alternating current (AC) to power the drive motors. The high frequency power inverter includes two parts, main circuit and control circuit.

How does AC inverter power affect DC input voltage?

The AC inverter power, P i required by the load determines how much current the inverter needs to draw from the DC source. This is influenced by the efficiency of the conversion process, represented by the power factor, PF. The DC input voltage, V i provided to the inverter affects the amount of current drawn.

How does a DC inverter work?

The inverter draws current from a DC source to produce AC power. The inverter uses electronic circuits to switch the DC input at high frequencies, creating a form of AC voltage. This process involves components like transistors, capacitors, and inductors to shape the waveform of the AC output.

What is a high voltage dc-ac sine wave inverter?

High voltage DC-AC sine wave inverters accept wide input ranges of 450V to 800Vdc. High frequency PWM technology enables high efficiency, compact construction and low weight. ABSOPULSE has recently added the CSH 500-F6 to its line of high input voltage DC-AC sine wave inverters.

What is inverter current?

Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the load, the input voltage to the inverter, and the power factor of the load. The inverter draws current from a DC source to produce AC power.

Learn More

- How many meters is the high voltage inverter safe

- How much does a 1000w voltage inverter cost

- Inverter high voltage output price

- 500v high voltage sine wave inverter

- How much does it cost to customize a DC inverter

- How much does a photovoltaic DC inverter cabinet cost

- How much frequency does a high frequency inverter require

- Inverter high voltage grid connection

- The difference between high voltage and low voltage inverter

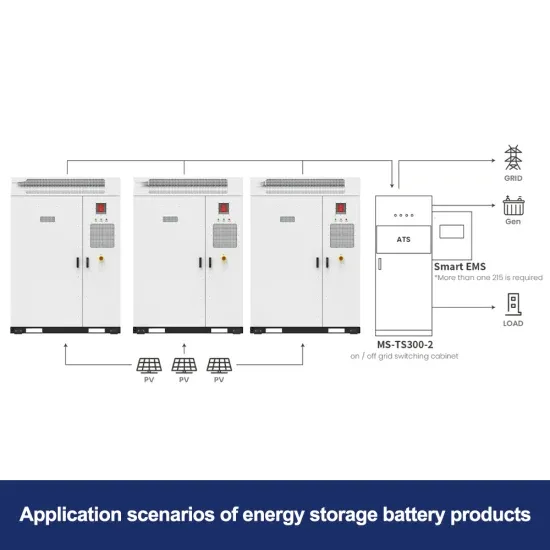

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.