Hybrid compatible grid forming inverters with coordinated

Aug 16, 2025 · This superior damping behavior stems from the high control bandwidth and dynamic voltage support capability inherent in grid-forming inverters, which allows them to

Grid Interconnection Study Procedures with Practical

Aug 1, 2024 · In this chapter, grid interconnection planning studies of inverter-based resources and high-voltage direct current (HVDC) projects will be discussed. An overview of the main

Hybrid Inverter

Sep 15, 2022 · Normal connect: The allowed grid voltage/frequency range when the inverter first me connect to the grid. Reconnect a er trip: The allowed grid voltage /frequency range for the

PV Array with Cascaded Multilevel Inverter and Medium

Mar 7, 2022 · The recent progress in power converters has resulted in grid integration of Renewable energy systems using Multilevel Inverter setup. This paper proposes a medium

Technical Note – Grids Supported by SolarEdge Inverte

Jul 8, 2025 · Supported grids 200-230V Corner Grounded Delta Grid * To verify that the inverter supports this grid voltage, see the relevant inverter datasheet.

High Voltage Solar Inverter DC-AC Kit

Sep 3, 2014 · High Voltage Solar Inverter DC-AC Kit 1 Introduction Inverters, especially solar inverters, have gained more attention in recent years. Solar inverters produce solar energy

Three Common Misconceptions About Grid-tied Inverters

Aug 27, 2024 · Discover common misconceptions about grid-tied inverters in solar PV systems, including voltage output, anti-islanding protection, and DC string voltage effects.

A Medium Voltage Grid-connected PV Inverter with a New Modular High

Mar 20, 2025 · This work proposes a medium voltage grid-connected inverter with modular high voltage gain converters for PV energy applications. The proposed topology utilizes

Two-Segment High-Performance PV Grid-Connected Inverter

Oct 15, 2024 · By analyzing the causes of grid-connected harmonic currents during the grid-connection process, a two-segment high-performance grid-connected inverter topology is

Single-Stage Three-Level Inverter: Approach for

Feb 10, 2025 · Abstract y systems depend on the power electronics that are needed to connect the battery to the grid. In most case two-stage designs are used to convert the battery DC

Grid Connected Inverter Reference Design (Rev. D)

May 11, 2022 · High-efficiency, low THD, and intuitive software make this design attractive for engineers working on an inverter design for UPS and alternative energy applications such as

High Efficiency Solar Deye Hybrid Inverter 20kw Three Phase High

Optimal Battery Compatibility: * Engineered for high voltage lithium-ion batteries, the Deye SUN inverters support a voltage range of 160-700V. This broad compatibility range ensures higher

Voltage Rise & Solar Shutdowns. Why It

Nov 4, 2019 · Learn why voltage rise is an increasing problem for solar owners and the wider grid. Plus get a step-by-step checklist to diagnose and fix it for

Twoâ stage microâ grid inverter with highâ voltage gain

Dec 22, 2020 · The proposed system consists of a high-voltage gain switched inductor boost inverter cascaded with a current shaping (CS) circuit followed by an H-bridge inverter as a

Robust Line-Voltage Sensorless Control and

Jun 23, 2011 · This paper presents a robust control scheme for high power quality grid connection of inductor–capacitor–inductor (LCL)-filtered distributed generation (DG) inverters. The

Two‐stage micro‐grid inverter with high‐voltage

Nov 1, 2013 · This study proposes a new two-stage high voltage gain boost grid-connected inverter for AC-module photovoltaic (PV) system. The proposed

Grid-connected photovoltaic inverters: Grid codes,

Jan 1, 2024 · With the development of modern and innovative inverter topologies, efficiency, size, weight, and reliability have all increased dramatically. This paper provides a thorough

On Grid Inverter, Grid Tie Inverter | inverter

High performance solar grid tie inverter is 500 watt AC output power with low price, pure sine wave, 12 volt/ 24 volt DC voltage input to 110 volt/ 230 volt AC output, precise MPPT and APL

6 FAQs about [Inverter high voltage grid connection]

What is a high voltage grid connected inverter?

The high-voltage grid-connected inverter has a high-voltage output capacity. The AC grid-connected voltage levels of 1100V DC high-voltage inverters are generally 480Vac, 500Vac, 540Vac, etc., and the AC grid-connected voltage level of 1500V DC high-voltage inverters is 800Vac.

What is a grid-connected inverter?

In the grid-connected inverter, the associated well-known variations can be classified in the unknown changing loads, distribution network uncertainties, and variations on the demanded reactive and active powers of the connected grid.

What is a good THD for a grid-connected inverter?

The THD should be less than 5% in many grid code standards. The power density of a grid-connected inverter topology systems can be influenced by several factors such as: 1. Converter Topology: The specific converter topology chosen for the grid-connected inverter can impact power density.

What is the control design of a grid connected inverter?

The control design of this type of inverter may be challenging as several algorithms are required to run the inverter. This reference design uses the C2000 microcontroller (MCU) family of devices to implement control of a grid connected inverter with output current control.

Can grid-connected PV inverters improve utility grid stability?

Grid-connected PV inverters have traditionally been thought as active power sources with an emphasis on maximizing power extraction from the PV modules. While maximizing power transfer remains a top priority, utility grid stability is now widely acknowledged to benefit from several auxiliary services that grid-connected PV inverters may offer.

What is a high-voltage grid connection?

Next, we will explain in detail the differences between these two grid connection methods. High-voltage grid connection usually refers to directly connecting a photovoltaic power station to a medium-high voltage power grid. Its voltage level is generally above 10 kilovolts. Common voltage levels include 10 kV, 35 kV, etc.

Learn More

- Inverter high voltage grid connection

- Energy storage system high voltage grid connection

- Bangkok distributed energy storage high voltage grid connection

- Which inverter is better for Swedish communication base station grid connection

- High quality 5kw on grid inverter in China Price

- Libya communication base station inverter grid connection construction bidding

- Does the inverter have high voltage

- Cheap high quality on grid inverter Price

- Technology of inverter grid connection for Nicaragua communication base station

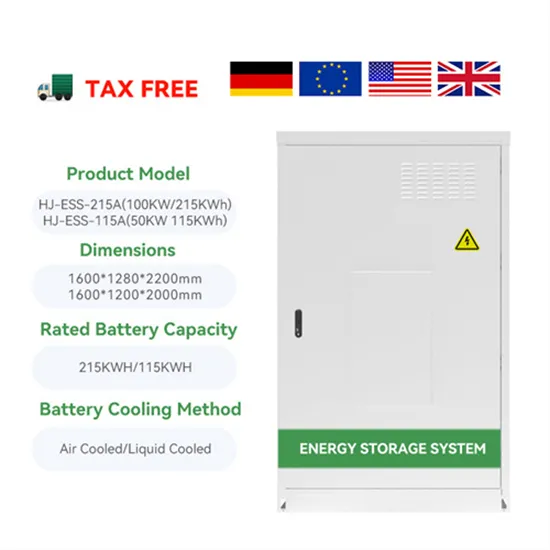

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.