LiFePO4 Voltage Guide: Charge, Float & Battery

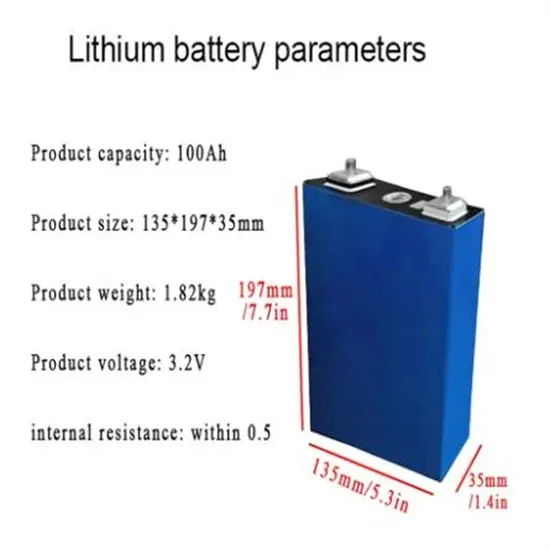

Jan 19, 2024 · The nominal voltage of a single lithium iron phosphate battery is 3.2 V, the charging voltage is 3.6 V, and the discharge cut-off voltage is 2.0 V.

LFP Vs Lithium Ion: Pros And Cons?

May 26, 2025 · LFP (Lithium Iron Phosphate) batteries prioritize safety and longevity with stable thermal performance, ideal for stationary storage and EVs requiring frequent cycling.

What Are LiFePO4 Batteries, and When Should

Sep 7, 2022 · How Are LiFePO4 Batteries Different? Strictly speaking, LiFePO4 batteries are also lithium-ion batteries. There are several different variations in

Lithium Iron Phosphate (LFP)

Oct 5, 2023 · Lithium Iron Phosphate (LFP) Lithium ion batteries (LIB) have a dominant position in both clean energy vehicles (EV) and energy storage systems (ESS), with significant

What You Need to Know About LiFePO4 vs. Other Lithium

Sep 12, 2024 · Understanding the differences between lithium battery chemistries is crucial for selecting the right power source for your needs. Lithium iron phosphate (LiFePO4) batteries

The Comprehensive Guide to LiFePO4 Voltage Chart

The LiFePO4 Voltage Chart stands as an essential resource for comprehending the charging levels and condition of Lithium Iron Phosphate batteries. This visual aid showcases the voltage

The difference between high-voltage and low-voltage lithium iron

This article discusses in detail the main differences between high-voltage and low-voltage lithium iron phosphate batteries in terms of voltage range, energy density, application scenarios, etc.

Why is there a voltage difference in lithium iron phosphate batteries?

It is normal for the charging and discharging platform of lithium iron phosphate batteries to have a voltage difference. Although it can withstand overcharging, charging to a higher voltage will

How Does A Lithium Iron Phosphate Battery Work?

May 26, 2025 · Lithium Iron Phosphate (LiFePO4) batteries operate through the movement of lithium ions between a cathode made of LiFePO4 and a graphite anode during

LiFePO4 vs. Lithium Ion Batteries: What''s the Best Choice for

The battery industry has advanced rapidly in recent years, making superior technologies more affordable. Lithium iron phosphate (also known as LiFePO4 or LFP) is the latest development

What Are the Pros and Cons of Lithium Iron Phosphate Batteries?

Jan 5, 2024 · Lithium iron phosphate (LiFePO4) batteries offer several advantages, including long cycle life, thermal stability, and environmental safety. However, they also have drawbacks

How Does A Lithium Iron Phosphate Battery Work?

May 26, 2025 · How Does A Lithium Iron Phosphate Battery Work? Lithium Iron Phosphate (LiFePO4) batteries operate through the movement of lithium ions between a cathode made of

Explore LFP Battery Raw Material: LFP Cathode

Jan 30, 2024 · Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing

Charge voltage experiments with lithium iron

Dec 5, 2023 · First, the charging starts at a lower voltage than lithium ion, with some charging starting as low as 3V. Second, there is significant charging at

6 FAQs about [What is the voltage difference of lithium iron phosphate battery station cabinet ]

Does iron phosphate increase capacity with charge voltage?

The results with iron phosphate batteries also show an increase in capacity with charge voltage. However, charging starts at a lower voltage than lithium ion, with some charging starting as low as 3V.

How many volts does a lithium phosphate battery take?

A lithium iron phosphate battery doesn't require being fully charged, but around 3.3 volts is the magic number for significant charging. If all you have available is 3.3 volts and you don't mind the loss in capacity, you could use it for charging.

How does a lithium iron phosphate battery work?

Lithium Iron Phosphate (LiFePO4) batteries operate through the movement of lithium ions between a cathode made of LiFePO4 and a graphite anode during charging/discharging. Their unique olivine crystal structure provides thermal stability, reducing combustion risks.

How many volts does a LiFePO4 battery charge?

LiFePO4 batteries have a charging voltage of 3.65 Volts per cell. PowerStream offers 1-cell to 8-Cell chargers for LiFePO4 packs. How much voltage does it take to charge a lithium-ion battery? This passage is about chargers for LiFePO4 batteries and mentions the charging voltage.

What is a LiFePO4 voltage chart?

The LiFePO4 Voltage Chart stands as an essential resource for comprehending the charging levels and condition of Lithium Iron Phosphate batteries. This visual aid showcases the voltage spectrum from full charge to complete discharge, enabling users to determine the present charge status of their batteries.

What is a lithium iron phosphate (LiFePO4) battery?

Lithium Iron Phosphate (LiFePO4) batteries are recognized for their high safety standards, excellent temperature resistance, fast discharge rates, and long lifespan. These high-capacity batteries effectively store energy and power a variety of devices across different environments.

Learn More

- Can the lithium iron phosphate battery station cabinet be used at low temperatures

- 40 kWh lithium iron phosphate battery station cabinet

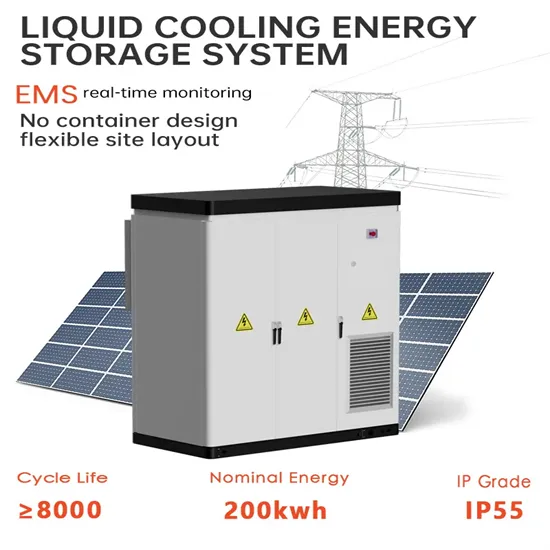

- Liquid-cooled energy storage lithium iron phosphate battery station cabinet

- How to check the model of lithium iron phosphate battery station cabinet

- What is the actual life of a 60v lithium iron phosphate battery pack

- Lithium iron phosphate battery service life of energy storage cabinet

- Mexican energy storage lithium iron phosphate battery

- Freetown lithium iron phosphate energy storage battery

- Tajikistan lithium iron phosphate battery EK cylindrical

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.