Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell

Manufacturing of Silicon Solar Cells and Modules

Jun 13, 2023 · To get from cell making to module making requires proper preparation of pristine wafers to be physically and electrically connected in series to achieve the rated output of a PV

SILICON WAFER/CELL SHEET, PHOTOVOLTAIC CELL ASSEMBLY

Embodiments of the present invention relate to the field of photovoltaics, and provide a silicon wafer/cell sheet, a photovoltaic cell assembly, a carrier, and a design and arrangement

The solar cell wafering process

May 21, 2024 · AbstrAct The process of wafering silicon bricks represents about 22% of the entire production cost of crystalline silicon solar cells. In this paper, the basic principles and

Manufacturing Solar Cells: Assembly and Packaging

Nov 16, 2017 · Today''s solar cells can be described as the coexistence of three different generations: crystalline silicon, thin film, and dye sensitized. Along with the development of

Influence of novel photovoltaic welding strip on the power

Oct 1, 2021 · However, the composite structure of reflective film materials during operation canreduce the reliability of PV assembly, and low the production efficiency of PV assembly.

Environmental impact of monocrystalline silicon photovoltaic

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Solar Silicon Wafer Market | Global Market Analysis Report

Aug 11, 2025 · Solar Silicon Wafer Market Solar Silicon Wafer Market Size and Share Forecast Outlook 2025 to 2035 The solar silicon wafer market is projected to grow from USD 16.8 billion

What Is a Silicon Wafer for Solar Cells?

What Is a Wafer-Based Solar Cell? Solar cells are an essential part of systems that convert sunlight into electricity using the photovoltaic effect. Wafer-based solar cells are the most

SILICON WAFER/CELL SHEET, PHOTOVOLTAIC CELL

Feb 7, 2022 · The photovoltaic cell module is formed by ar-raying a plurality of the above-mentioned cells. The car-rier has an opening, the length of the opening of the car-rier is equal

Photovoltaic silicon wafer and battery cell assembly

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product''s quality and efficiency: Silicon Ingot and Wafer

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Solar Cell Production: from silicon wafer to cell

Apr 12, 2025 · Sand → Silicon → Wafer → Photovoltaic Cell → Solar Panel. Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar

A review of interconnection technologies for improved crystalline

Sep 15, 2015 · The identification, adoption and utilisation of reliable interconnection technology to assembly crystalline silicon solar cells in photovoltaic (PV) m

The solar energy industry has witnessed remarkable

Mar 1, 2025 · What Are Solar Wafers? A solar wafer, also known as a silicon wafer, is a thin slice of crystalline silicon that serves as the foundation for fabricating integrated circuits in

SILICON WAFER/CELL SHEET, PHOTOVOLTAIC CELL

Jan 19, 2022 · The photovoltaic cell module is formed by ar-raying a plurality of the above-mentioned cells. The car-rier has an opening, the length of the opening of the car-rier is equal

Silicon Wafer Battery Assembly Process

Polygonal-shaped wafers help simplify the manufacturing and assembly of PV modules comprised of multiple solar cells. Much of the cost of manufacturing solar panels comes from the silicon

Crystalline Silicon Photovoltaic Module Manufacturing

Feb 10, 2020 · Executive Summary Over the past decade, the crystalline-silicon (c-Si) photovoltaic (PV) industry has grown rapidly and developed a truly global supply chain, driven

The solar cell wafering process

May 21, 2024 · In this paper, the basic principles and challenges of the wafering process are discussed. The multi-wire sawing technique used to manufacture wafers for crystalline silicon

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · In the following sections, the technological processes from preparing pure silicon, to silicon wafer fabrication, to cell design and fabrication, and finally to PV module design and

6 FAQs about [Photovoltaic cell silicon wafer assembly]

How are solar silicon wafers made into cells?

How Solar Silicon Wafers Are Made into Cells The process of transforming solar silicon wafers into cells involves several meticulous steps, including wafer slicing, doping, and passivation, which culminate in the creation of functional photovoltaic cells.

Can silicon wafers be used as a starting material for solar cells?

9.4.2.2. PERT, TOPCon, and Bifacial Cells Phosphorous-doped N-type silicon wafers retain lifetimes on the order of milliseconds under the same stresses and therefore can be used as a starting material for high-efficient solar cells.

What is the PV cell manufacturing process?

The PV cell manufacturing process is a complex and precise endeavor that transforms raw materials into high-efficiency solar cells. From the initial production of silicon wafers to the final assembly of solar modules, each step requires strict quality control measures to ensure optimal performance and longevity.

Can wire sawing produce crystalline wafers for solar cells?

Wire sawing will remain the dominant method of producing crystalline wafers for solar cells, at least for the near future. Recent research efforts have kept their focus on reducing the wafer thickness and kerf, with both approaches aiming to produce the same amount of solar cells with less silicon material usage.

How are silicon wafers made?

Cell Fabrication – Silicon wafers are then fabricated into photovoltaic cells. The first step is chemical texturing of the wafer surface, which removes saw damage and increases how much light gets into the wafer when it is exposed to sunlight. The subsequent processes vary significantly depending on device architecture.

Are solar PV modules made in a factory?

While most solar PV module companies are nothing more than assemblers of ready solar cells bought from various suppliers, some factories have at least however their own solar cell production line in which the raw material in form of silicon wafers is further processed and refined.

Learn More

- Photovoltaic cell silicon wafers and module silicon wafers

- Htj photovoltaic cell assembly

- Crystalline silicon cell photovoltaic modules

- Photovoltaic cell shingled assembly

- Monocrystalline silicon high power photovoltaic panels

- Doha monocrystalline silicon single glass photovoltaic modules

- Huawei Ottawa polycrystalline silicon photovoltaic panels

- Small monocrystalline silicon photovoltaic panel

- Perovskite photovoltaic cell components

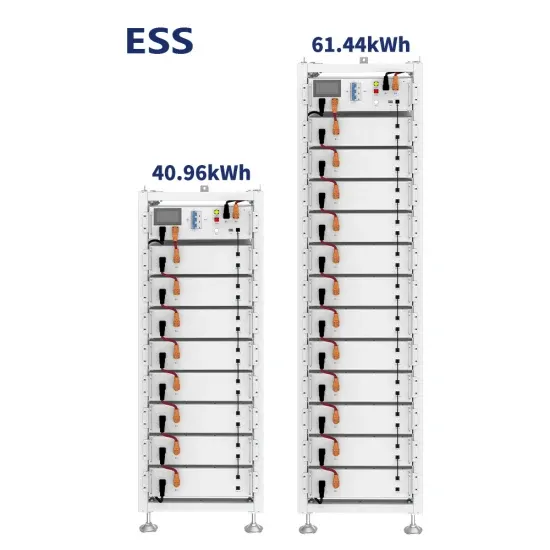

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.