Photovoltaic (PV) Cell Types | Monocrystalline,

5 days ago · The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar

Comparative Study of Two Commercial Photovoltaic Panels

Nov 22, 2019 · Monocrystalline silicon photovoltaic panels generate higher maximum power and have lower temperatures than amorphous silicon panels, with a degradation rate of 1.02% for

Defect analysis and performance evaluation of photovoltaic

Jan 8, 2025 · Abstract This paper presents a defect analysis and performance evaluation of photovoltaic (PV) modules using quantitative electroluminescence imaging (EL). The study

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Their distinguishing feature is their cells, which are made of monocrystalline silicon, a pure and homogeneous material that guarantees superior energy performance

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · Monocrystalline silicon solar panels have an efficiency range of 18% to 22%, making them one of the most efficient photovoltaic panels available.

Monocrystalline Solar Panels Explained

Aug 13, 2025 · Monocrystalline solar panels explained Are monocrystalline solar panels a good investment for UK homeowners? With 44% of the solar PV market share, monocrystalline

What are monocrystalline solar panels?

Jun 15, 2025 · Monocrystalline solar panels are a type of solar panel design that uses a single silicon crystal to capture sunlight and generate energy. This design gives monocrystalline

Why Monocrystalline Silicon PV Panels Are the Best Choice

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

Exploring Monocrystalline Solar Panels: A Comprehensive

Nov 9, 2023 · 2. Can SolarClue® explain the manufacturing process of monocrystalline solar cells, detailing how single-crystal silicon ingots are produced, sliced into wafers, and

The Pros and Cons of Monocrystalline Solar Panels

5 days ago · One type of solar panel that has gained significant attention is the monocrystalline solar panel. Monocrystalline solar panels are known for their

30 watt Monocrystalline silicon solar module, 15 watt solar panel

Mar 22, 2025 · Operating Current (Imp): 1.66A Dimension: 400x500x30mm Encapsulation methods: photovoltaic tempered glass Material: monocrystalline silicon cell With frame: silver

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

SUNYIMA 10pcs Mini Monocrystalline Solar Cells Solar

Apr 29, 2020 · About this item 【Accurate power】All data are actually measured under the condition that the solar light is sufficient. In full sunlight, the voltage will be higher than 2V. 【Product Parameter】10Pcs Monocrystalline silicon solar panels;Power:2V

Things You Need to Know About Monocrystalline Solar Panels

Jul 26, 2025 · What are the things you need to know about monocrystalline solar panels? Distinct appearance because of the single crystal structure Higher efficiency rates compared to other

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · What is the Meaning of Monocrystalline Silicon Solar Panels? When discussing solar panel meaning, monocrystalline silicon solar panels refer to

Small 30w 50w Monocrystalline Silicon Solar Panel Shingles

Key attributes Cell size 125mmx125mm Place of Origin Guangdong, China Panel Dimensions 540*280*2.5 mm Brand Name ZYCXEG Model Number SPP090 Panel Efficiency 21% Product

Enhancement of efficiency in monocrystalline silicon

Sep 6, 2024 · As the representative of the first generation of solar cells, crystalline silicon solar cells still dominate the photovoltaic market, including monocrystalline and polycrystalline

Monocrystalline solar cells and their efficiency

Apr 11, 2023 · What are monocrystalline cells? Monocrystalline Solar Panels A solar panel, as you probably know, consists of photovoltaic (PV) cells – small

6 FAQs about [Small monocrystalline silicon photovoltaic panel]

What are monocrystalline solar panels?

Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which allows the electric current to flow more smoothly, with less resistance. This ultimately means they have the highest efficiency ratings, longest lifespans, and best power ratings on the market, ahead of all other types of solar panels.

Are monocrystalline photovoltaic panels a good choice?

Monocrystalline photovoltaic panels are at the forefront of solar technology due to their efficiency, durability and ability to generate energy even in confined spaces. They are considered an excellent choice for anyone wishing to install a high quality photovoltaic system, whether for residential or industrial use.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

How many solar cells are in a single monocrystalline panel?

Based on their size, a single monocrystalline panel may contain 60-72 solar cells, among which the most commonly used residential panel is a 60-cells. Features A larger surface area due to their pyramid pattern. The top surface of monocrystalline panels is diffused with phosphorus, which creates an electrically negative orientation.

What is a mono solar panel?

Mono panels have a uniform black color, which is a result of the single-crystal silicon structure. Their sleek and uniform appearance makes them aesthetically pleasing and a popular choice for residential and commercial installations where the look of the solar array is a consideration.

What makes monocrystalline solar panels darker?

This process, called the Czochralski method, is what makes monocrystalline solar panels darker and more efficient then their polycrystalline counterparts. A single ingot is more able to absorb light, which gives them their black appearance – plus chemical etching and anti-reflective coating removes any grey undertones.

Learn More

- Monocrystalline silicon solar photovoltaic panel 400w

- Male monocrystalline silicon photovoltaic panel manufacturer

- How many kilowatt-hours of electricity can a monocrystalline silicon photovoltaic panel generate in a day

- Thailand monocrystalline silicon photovoltaic panel manufacturer

- Accra monocrystalline silicon photovoltaic panel charging

- Monocrystalline silicon photovoltaic panel conversion

- Huawei photovoltaic panel monocrystalline silicon parameters

- Which type of monocrystalline solar photovoltaic panel is better

- Germany s new energy photovoltaic glass components monocrystalline silicon

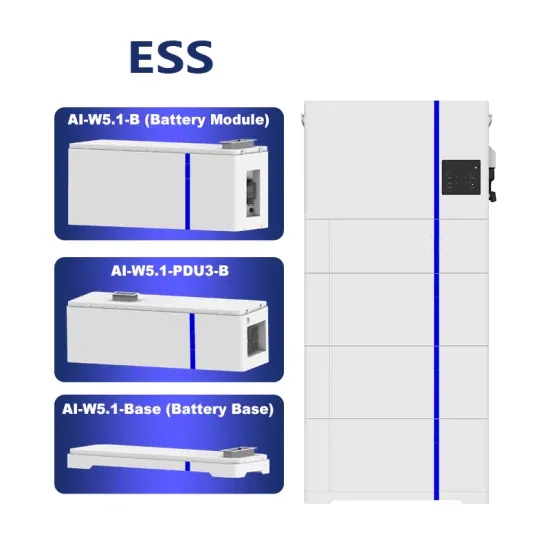

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.