The Silicon Age

Jul 15, 2025 · Silicon is a discreet chemical element, but it is omnipresent and essential to our daily lives. Found in the Earth''s crust in the form of silica or silicates, it is a component of

Performance Investigation of Tempered Glass‐Based Monocrystalline

Oct 31, 2021 · This research aims at performing an experimental study to investigate the electrical performance of novel tempered glass-based PV panels using two different types of solar cells:

PV Cells 101: A Primer on the Solar Photovoltaic

Dec 3, 2019 · Part 1 of the PV Cells 101 primer explains how a solar cell turns sunlight into electricity and why silicon is the semiconductor that usually does it.

Monocrystalline silicon module_Products_Yixin PV

Monocrystalline silicon module-Yixin PVYixin photovoltaic new energy investment (Guangdong) Co., Ltd. takes "lean", "automation", "informatization" and "intelligence" as the design concept,

Photovoltaic (PV) Cell Types | Monocrystalline,

6 days ago · The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar

European glass-glass PV modules particularly climate-friendly

Sep 24, 2021 · In the study, Fraunhofer ISE calculated the carbon footprint of six monocrystalline silicon photovoltaic modules. Modules manufactured in China, Germany and the European

THE RECOVERY OF GLASS AND SILICON FROM

Dec 3, 2024 · Victor GAŞPAR Engineering Faculty, "Lucian Blaga" University of Sibiu ABSTRACT: The implementation of photovoltaic (PV) panels has seen significant growth in

CO2 EMISSIONS OF SILICON PHOTOVOLTAIC MODULES

Sep 27, 2022 · In general, the CO2 emissions of PV systems are significantly lower than those of conventional energy generation using, for instance, coal, but there are considerable

A review of solar photovoltaic technologies: developments,

Jul 1, 2025 · Solar photovoltaic (PV) technology has emerged as a key renewable energy solution, yet its widespread adoption faces several technical and economic challenges. This review

Crystallization processes for photovoltaic silicon ingots:

Sep 1, 2024 · The choice of the crystallization process depends on several factors, including cost, efficiency requirements and market demand. Photovoltaic silicon ingots can be grown by

Material intensity and carbon footprint of crystalline silicon

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

European Glass-Glass Photovoltaic Modules Are

Sep 23, 2021 · European Glass-Glass Photovoltaic Modules Are Particularly Climate-Friendly In a new study, researchers at the Fraunhofer Institute for Solar Energy Systems ISE have

Window-Integrated PV Glass: The Future of Solar

Feb 19, 2025 · Window-integrated PV glass represents a significant advancement in building-integrated photovoltaics, offering a compelling blend of sustainable

Monocrystalline Silicon Double Glass Cell Components

Why Monocrystalline Silicon Double Glass Cells Dominate Modern Solar Projects Imagine a solar panel that laughs at hailstorms, shrugs off desert heat, and still delivers top performance after

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell

European Glass-Glass Photovoltaic Modules Are

Sep 23, 2021 · In the study, Fraunhofer ISE calculated the CO2 footprint of six monocrystalline silicon photovoltaic modules. Modules manufactured in China,

Trina Solar launches N-type i-TOPCon double-glass bifacial

Jun 13, 2019 · The new i-TOPCon double glass PV modules integrate these N-type bifacial i-TOPCon cells with over 80% bifaciality, multi-busbar (MBB) design, full square

Photovoltaics Report

Jun 6, 2025 · Energy Payback Time Silicon usage for silicon cells has been reduced significantly during the last 20 years from around 16 g/Wp (in 2004) to about 2.0 g/Wp in 2024 due to

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · This study investigates the life cycle environmental impact of two different single-crystalline silicon (sc-Si) PV module designs, glass-backsheet (G-BS) and glass-glass (G-G)

What is the difference between a double-sided double-glass

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

6 FAQs about [Germany s new energy photovoltaic glass components monocrystalline silicon]

Are glass-glass solar modules better than glass-film solar panels?

In addition, glass-glass solar modules have a longer service life and less degradation than their glass-film counterparts, which also has a positive effect on the CO2 footprint. As to the kWh generated, the frameless glass-glass module causes 22 to 27 percent fewer CO2 emissions than the glass-backsheet module, the researchers explained

Are glass-glass PV modules a good choice?

Glass-glass PV modules (b) do not require an aluminum frame and therefore have a lower carbon footprint than PV modules with backsheet (a). Although photovoltaic modules convert sunlight into electricity without producing emissions, PV-generated solar energy does produce CO2 emissions during production, transport and at the end of module life.

Do glass-glass solar panels reduce emissions?

In the process, they also found that glass-glass modules enable an additional emissions reduction ranging between 7.5 to 12.5 percent compared to PV modules with backsheet films, regardless of their production location.

Are solar modules based on silicon solar cells a green technology?

Modules based on silicon solar cells are dominating the photovoltaic (PV) market and are considered as a green technology for the supply of renewable and emission-free energy.

Do silicon photovoltaic modules produce less CO2?

In a new study, researchers at the Fraunhofer ISE have calculated that silicon photovoltaic modules manufactured in the European Union produce 40 percent less CO2 than modules manufactured in China.

What percentage of glass-backsheet modules are produced in Germany?

Glass-backsheet modules: P = 366 W p, η = 19.79%. Glass-glass modules: P = 359 W p, η = 19.40%. Including production, transport and end-of-life. Excluding BOS, installation and operation. Results of glass-backsheet modules produced in Germany are scaled to 1. Absolute values are given in SI.

Learn More

- Praia New Energy BIPV Photovoltaic Glass Components

- Photovoltaic glass and monocrystalline silicon solar energy

- The relationship between photovoltaic glass and new energy

- Monrovia s first batch of new energy photovoltaic sites

- New Zealand Auckland Photovoltaic Energy Storage Policy

- Riyadh New Energy Photovoltaic Inverter

- Huawei photovoltaic glass film components

- Production of monocrystalline silicon photovoltaic panels

- Photovoltaic new energy storage cabinet

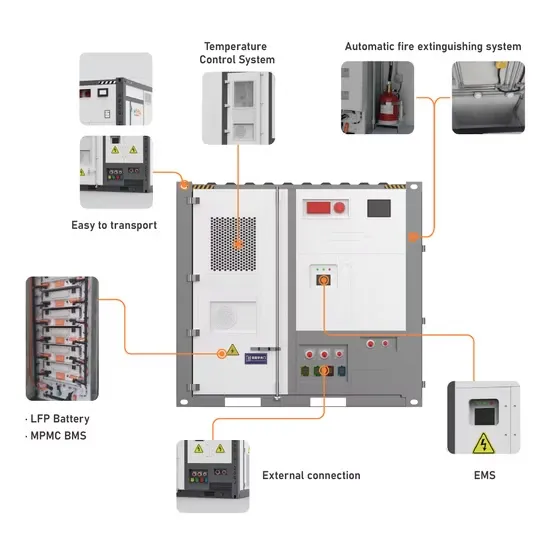

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.