PV Cells 101: A Primer on the Solar Photovoltaic

Dec 3, 2019 · Part 1 of the PV Cells 101 primer explains how a solar cell turns sunlight into electricity and why silicon is the semiconductor that usually does it.

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Monocrystalline photovoltaic panels are advanced devices designed to convert sunlight into electrical energy through a process called the photovoltaic effect. Their

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · These photovoltaic modules use high-efficiency monocrystalline silicon cells (the cells are made of a single crystal of very high-purity silicon) to

Performance Investigation of Tempered Glass‐Based Monocrystalline

Oct 31, 2021 · This research aims at performing an experimental study to investigate the electrical performance of novel tempered glass-based PV panels using two different types of solar cells:

Health and Safety Concerns of Photovoltaic Solar Panels

The primary output from this purification process is polysilicon, the precursor to the silicon wafers used to manufacture the integrated circuits at the heart of most electronics as well as

Dependence of spectral factor on angle of incidence for monocrystalline

Jan 1, 2022 · This section reports the roles of measured AOI-dependent spectral reflectivity of monocrystalline silicon solar cells and the spectral transmissivity of the cover glass on the

as 550 Watt Monocrystalline Silicon 550wp PV Solar Power Energy

Apr 3, 2025 · as 550 Watt Monocrystalline Silicon 550wp PV Solar Power Energy Panel Module, Find Details and Price about Solar Panels Solar Panels System from as 550 Watt

Material intensity and carbon footprint of crystalline silicon

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

High-efficiency Monocrystalline Silicon Solar Cells:

In this paper, the typical high-efficiency c-Si solar cells with conversion efficiencies of 25% or above are firstly summarized. The corresponding device structure, key technology and

How Do Solar Cells Work? Photovoltaic Cells

Jul 25, 2024 · Key takeaways A photovoltaic cell is the most critical part of a solar panel that allows it to convert sunlight into electricity. The two main types of

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and development efforts that lead to

Glass-free PV modules tested on bulk cargo ships

Aug 7, 2025 · Japan''s Eco Marine Power announced a trial of an integrated solar PV system aboard a bulk cargo ship to demonstrate both practicality and performance. It features glass

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · This study will be useful for future PV LCA practitioners as it comprehensively addresses the potential environmental impact of single-crystalline silicon glass-glass modules

Monocrystalline vs Polycrystalline Solar Cells and How to

Mar 12, 2025 · Monocrystalline and polycrystalline silicon solar panels With the rapid development of solar photovoltaic energy storage, its solar panel technology update iteration is also very

Holistic Assessment of Monocrystalline Silicon (mono-Si) Solar

Jun 16, 2023 · With the rising demand for lower carbon energy technologies to combat global warming, the market for solar photovoltaics (PVs) has grown significantly. Inevitab

Environmental impact assessment of monocrystalline silicon solar

Jan 20, 2016 · Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate the

Enhancement of efficiency in monocrystalline silicon

Sep 6, 2024 · Among them, photovoltaic cells made of silicon with a crystalline structure account for exceeding 90% of the photovoltaic market. Meanwhile, monocrystalline silicon has a

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Monocrystalline silicon solar cells are more efficient than polycrystalline silicon solar cells in terms of power output. In order to increase

6 FAQs about [Photovoltaic glass and monocrystalline silicon solar energy]

Are photovoltaic cells crystalline or monocrystalline?

Photovoltaic cells have therefore become a popular research direction. Among them, photovoltaic cells made of silicon with a crystalline structure account for exceeding 90% of the photovoltaic market. Meanwhile, monocrystalline silicon has a perfect crystal structure and large abundance.

Which crystalline solar cells dominate the photovoltaic market?

[email protected] Abstract. As the representative of the first generation of solar cells, crystalline silicon solar cells still dominate the photovoltaic market, including monocrystalline and polycrystalline silicon cells.

What is a monocrystalline silicon solar module?

Monocrystalline silicon represented 96% of global solar shipments in 2022, making it the most common absorber material in today’s solar modules. The remaining 4% consists of other materials, mostly cadmium telluride. Monocrystalline silicon PV cells can have energy conversion efficiencies higher than 27% in ideal laboratory conditions.

Can monocrystalline silicon solar cells reduce optical and electrical losses?

Together with five types of monocrystalline silicon solar cells, exploring ways to reduce optical and electrical losses in various cells to increase the conversion efficiency, taking into account the cost factor.

Do silicon photovoltaic modules produce less CO2?

In a new study, researchers at the Fraunhofer ISE have calculated that silicon photovoltaic modules manufactured in the European Union produce 40 percent less CO2 than modules manufactured in China.

What are the different types of crystalline silicon solar cells?

There are several crystalline silicon solar cell types. Aluminum back surface field (Al-BSF) cells dominated the global market until approximately 2018 when passivated emitter rear contact (PERC) designs overtook them due to superior efficiency.

Learn More

- Monocrystalline silicon photovoltaic panels solar energy

- Germany s new energy photovoltaic glass components monocrystalline silicon

- Doha monocrystalline silicon single glass photovoltaic modules

- Flexible monocrystalline silicon solar photovoltaic panels

- Photovoltaic on-site energy solar energy endurance

- Monocrystalline silicon photovoltaic panel manufacturer

- Energy storage container photovoltaic solar energy ranking

- How to match photovoltaic solar energy with inverter

- Photovoltaic energy storage cabinet solar product price

Industrial & Commercial Energy Storage Market Growth

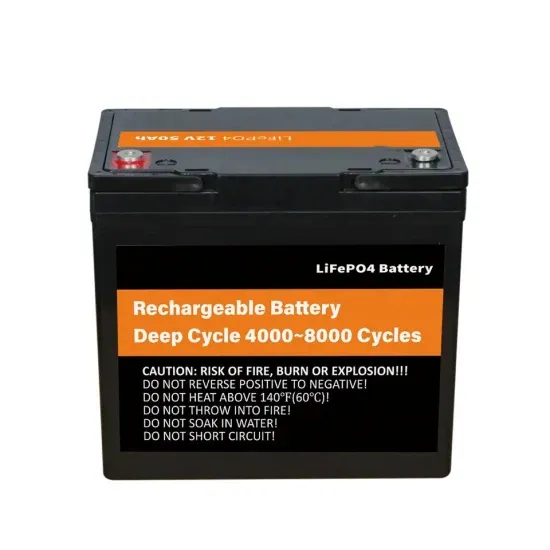

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

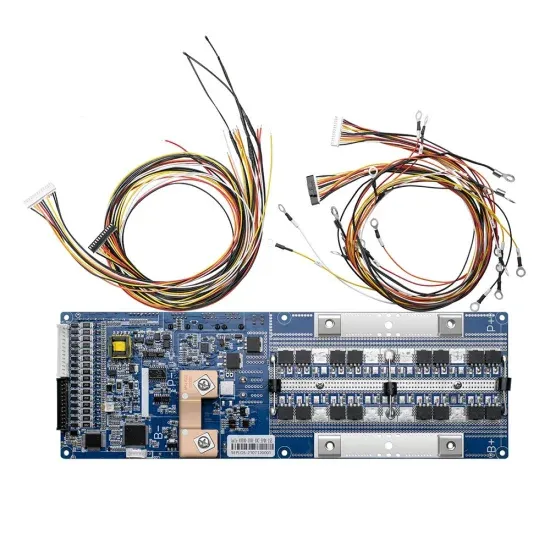

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.