SINGLE GLASS MONOCRYSTALLINE SILICON PV MODULES

Single glass solar power generation glass Multiple modern glass and window products based on novel glazing designs, metal-dielectric coatings, and proprietary interlayer types have been

Experimental investigation on the combustion performance of single

Jun 15, 2025 · Under similar glass material conditions, double-glazed modules exhibited superior combustion performance compared to their single-glass counterparts. Therefore, locations

Photovoltaic (PV) Module Technologies: 2020

Nov 2, 2021 · Technologies based on crystalline silicon (c-Si) dominate the current PV market, and their MSPs are the lowest; the figure only shows the MSP for monocrystalline monofacial

Concentrated PV Cells: High-Efficiency Solar Solutions for

4 days ago · 18% reorder rate 195 interested customers Matches all 2/2 requirements N-Type Monocrystalline High Efficiency 575W-600W Solar Panel CE for UL for Half Cell Single Glass

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Their study revealed that in both types of monocrystalline silicon PV modules, the production of monocrystalline silicon cells contributed the most to global warming potential,

High-efficiency Monocrystalline Silicon Solar Cells:

In this paper, the typical high-efficiency c-Si solar cells with conversion efficiencies of 25% or above are firstly summarized. The corresponding device structure, key technology and

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · How is a monocrystalline solar panel made Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by

Study of the Effects of Dust, Relative Humidity,

Aug 9, 2013 · The sensitivity of various solar photovoltaic technologies to dust, temperature, and relative humidity is investigated for Doha''s environment.

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · This study will be useful for future PV LCA practitioners as it comprehensively addresses the potential environmental impact of single-crystalline silicon glass-glass modules

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Environmental impact of monocrystalline silicon photovoltaic modules

Download Citation | On Jun 1, 2025, Xuerou Sheng and others published Environmental impact of monocrystalline silicon photovoltaic modules | Find, read and cite all the research you need on

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Photovoltaic Cells for Sale: High-Efficiency Solar Solutions

1 day ago · 100% reorder rate 98 interested customers Matches all 2/2 requirements Price 12BB 210mm Monocrystalline PV Photovoltaic Solar Cells for Sale $0.52-0.65 Min. order: 50000

Explanation of the principle of monocrystalline silicon

Photovoltaic (PV) installations have experienced significant growth in the past 20 years. During this period, the solar industry has witnessed technological advances, cost reductions, and

Life cycle assessment on PERC solar modules

Aug 1, 2021 · According to the statistics of the International Energy Agency (IEA) Photovoltaic Power Systems Program (PVPS), as of 2019, the global cumulative installed capacity of

Performance analysis of partially shaded high-efficiency

Sep 16, 2024 · The experimental approach of this paper aims to investigate single cell shading in high efficiency monocrystalline silicon PV PERC modules.

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Monocrystalline silicon solar energy specifications

What is a Monocrystalline Solar Module? Monocrystalline solar modules are panels assembled using ''''mono'''' cells - solar cells composed of single-crystal silicon. The single-crystal

6 FAQs about [Doha monocrystalline silicon single glass photovoltaic modules]

What are crystalline silicon solar cells?

Crystalline silicon solar cells used crystalline silicon as the photovoltaic conversion material to convert solar energy into direct current electricity. At that time, there were two main types of silicon-based solar cells: monocrystalline silicon and polycrystalline silicon.

Are polycrystalline silicon solar cells better than MSSC?

Therefore, the conversion efficiency of polycrystalline silicon solar cells was usually lower than that of MSSC , and the consistency in optical, electrical, and mechanical properties of polycrystalline silicon was also inferior to that of monocrystalline silicon.

Is there a new LCI for crystalline silicon PV systems?

In late 2020, IEA PVPS released an updated LCI for PV systems that contains updates for crystalline silicon PV technology reflecting the year 2018, while some information, such as the amounts of auxiliary materials, are still based on 2011 .

How does monocrystalline silicon affect the environment?

The production process of monocrystalline silicon consumed significant quantities of chemicals such as hydrogen fluoride, resulting in the generation of substantial chemical by-products like silicon tetrachloride and dichlorosilane, which imposed considerable environmental impacts.

Why is single crystalline silicon preferred over multi-crystalline silicon?

Single-crystalline silicon was chosen over multi-crystalline silicon as it is the leading polysilicon feedstock with a market share of 65% in 2019 and expected market share of 80% by 2030 .

How much energy does a metallurgical-grade polycrystalline silicon PV system use?

Their findings showed that the total energy demand and carbon footprint for producing a 1 MWp metallurgical-grade polycrystalline silicon PV system were 2.11 × 10 7 MJ and 1.64 × 10 6 kg- CO 2 eq. Respectively.

Learn More

- German monocrystalline silicon photovoltaic modules

- Basseterre monocrystalline silicon photovoltaic modules

- Conversion rate of monocrystalline silicon photovoltaic modules

- Photovoltaic glass and monocrystalline silicon solar energy

- Alofi monocrystalline silicon photovoltaic panel manufacturer

- Flexible monocrystalline silicon photovoltaic panels

- Tirana double glass photovoltaic modules

- Monocrystalline silicon photovoltaic panel manufacturer

- Thailand monocrystalline silicon photovoltaic panel manufacturer

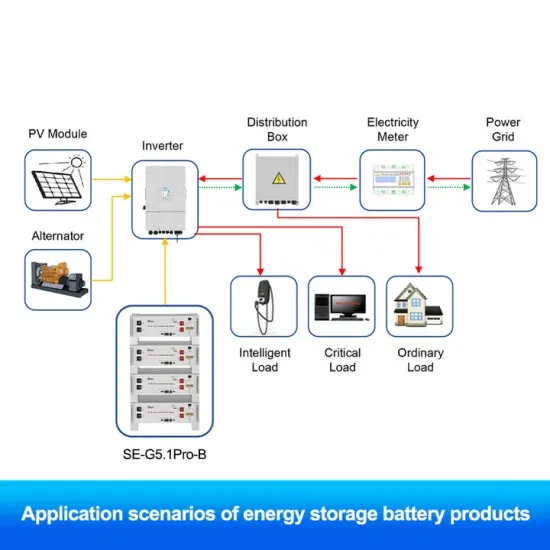

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.