What is the difference between monocrystalline and polycrystalline PV

Monocrystalline silicon photovoltaic modules use high-purity monocrystalline silicon materials, which have higher light conversion efficiency, typically ranging from 15% to 22%, generating

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · How is a monocrystalline solar panel made Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Experimental, economic and life cycle assessments of

Mar 15, 2022 · Experimental, economic and life cycle assessments of recycling end-of-life monocrystalline silicon photovoltaic modules Mitchell Shyan Wei Lim a, Dong He a, Jasmine

Defect analysis and performance evaluation of photovoltaic modules

Jan 8, 2025 · The study analyzed three common PV technologies: thin-film, monocrystalline silicon, and polycrystalline silicon. Experimental results indicate that monocrystalline silicon

High-efficiency Monocrystalline Silicon Solar Cells:

In this paper, the typical high-efficiency c-Si solar cells with conversion efficiencies of 25% or above are firstly summarized. The corresponding device structure, key technology and

Optimization of monocrystalline silicon photovoltaic

Jun 11, 2025 · Monocrystalline silicon photovoltaic modules represent a pivotal component in the solar PV manufacturing value chain. Their production process involves assem-bling

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The aim of this chapter is to present and explain the basic issues relating to the construction and manufacturing of PV cells and modules from c-Si. This includes the basic

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Environmental impact assessment of monocrystalline silicon

Jan 20, 2016 · Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate the

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Optimization of monocrystalline silicon photovoltaic module

Jun 11, 2025 · This study presents a systematic approach to enhance the efficiency of monocrystalline silicon photovoltaic module assembly lines using advanced simulation

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The present study aims to address this research gap by providing a temporal analysis of aluminum and glass intensity in crystalline silicon modules produced from 2006 to

Monocrystalline silicon solar energy specifications

What is a Monocrystalline Solar Module? Monocrystalline solar modules are panels assembled using ''''mono'''' cells - solar cells composed of single-crystal silicon. The single-crystal

Experimental comparison between Monocrystalline,

May 11, 2022 · PV cells are made from semiconductors that convert sunlight to electrical power directly, these cells are categorized into three groups depend on the material used in the

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · Understanding photovoltaic technology, and in particular, crystalline silicon PV technology is crucial for those seeking to adopt renewable energy

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Photovoltaic (PV) Module Technologies: 2020

Nov 2, 2021 · Technologies based on crystalline silicon (c-Si) dominate the current PV market, and their MSPs are the lowest; the figure only shows the MSP for monocrystalline monofacial

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Their study revealed that in both types of monocrystalline silicon PV modules, the production of monocrystalline silicon cells contributed the most to global warming potential,

Environmental impact of monocrystalline silicon photovoltaic modules

May 9, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Crystalline Silicon Photovoltaic Module Manufacturing

Feb 10, 2020 · Polycrystalline silicon or "polysilicon" is the feedstock used to make monocrystalline- or multicrystalline-silicon ingots, which are then sliced into wafers, fabricated

Monocrystalline silicon solar energy specifications

Download scientific diagram | Specifications of mono-crystalline silicon PV modules at STC from publication: Modeling a Simple Single-phase Grid-connected Photovoltaic System...

6 FAQs about [Basseterre monocrystalline silicon photovoltaic modules]

What is the difference between polycrystalline and monocrystalline solar panels?

At present, the polycrystalline and monocrystalline modules are mainly used in the rooftop or ground photovoltaic systems, the monocrystalline module has the good power generation yield and save the cost of land or rooftop with the same installed capacity.

How much does a crystalline silicon (c-Si) module cost?

Technologies based on crystalline silicon (c-Si) dominate the current PV market, and their MSPs are the lowest; the figure only shows the MSP for monocrystalline monofacial passivated emitter and rear cell (PERC) modules, but benchmark MSPs are similar ($0.25–$0.27/W) across the c-Si technologies we analyze.

What is a bifacial solar module?

LONGi launched its mono-PERC modules in 2016, featuring integrated PERC technology on monocrystalline silicon and low light degradation, and its cell efficiency has increased from 21% to 24.06%. Bifacial modules collect solar energy from both the front and back side of the module, increasing the total power output per module.

Do photovoltaic modules have a defect analysis and performance evaluation?

This paper presents a defect analysis and performance evaluation of photovoltaic (PV) modules using quantitative electroluminescence imaging (EL). The study analyzed three common PV technologies: thin-film, monocrystalline silicon, and polycrystalline silicon.

Do monocrystalline solar panels deteriorate after 5 years of Operation?

Table 9. Degradation of monocrystalline PV panels after 5 years of operation. The EL images of the monocrystalline solar panel, as shown in Fig. 5, reveal performance degradation caused by defects such as micro-cracks and folds, which create shaded areas and reduce the panel’s ability to convert solar energy into electricity.

How much power does a monocrystalline module use?

In 2019, typical 72-cell multicrystalline modules were rated at 320–350 W, whereas monocrystalline modules with half-cut cells were rated at 430–440 W. These trends may help explain the projected monocrystalline market share growing from 60% in 2019 to almost 90% by 2025 (ITRPV Working Group 2019).

Learn More

- German monocrystalline silicon photovoltaic modules

- Doha monocrystalline silicon single glass photovoltaic modules

- Conversion rate of monocrystalline silicon photovoltaic modules

- Thailand monocrystalline silicon photovoltaic panel manufacturer

- How many kilowatt-hours of electricity can a monocrystalline silicon photovoltaic panel generate in a day

- Small monocrystalline silicon photovoltaic panel

- Germany s new energy photovoltaic glass components monocrystalline silicon

- Monocrystalline silicon photovoltaic panels solar energy

- Male monocrystalline silicon photovoltaic panel manufacturer

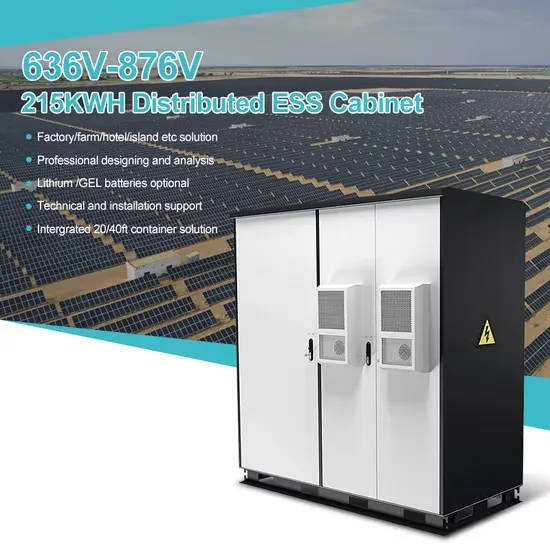

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.