Fraunhofer: Monocrystalline modules underperformed by 1.2%

Mar 12, 2025 · New research from German research organisation Fraunhofer ISE has found that in 2024 the average monocrystalline silicon PV module''s power output was 1.2% lower than its

Photovoltaic Cells for Sale: High-Efficiency Solar Solutions

1 day ago · 100% reorder rate 98 interested customers Matches all 2/2 requirements Price 12BB 210mm Monocrystalline PV Photovoltaic Solar Cells for Sale $0.52-0.65 Min. order: 50000

Photovoltaics Report

Jun 6, 2025 · In the laboratory, the best performing modules are based on monocrystalline silicon with 25.4% efficiency. Record efficiencies demonstrate the potential for further efficiency

Analysis of electroluminescence and infrared thermal images

Oct 1, 2018 · Analysis of electroluminescence and infrared thermal images of monocrystalline silicon photovoltaic modules after 20 years of outdoor use in a solar vehicle

Monocrystalline Photovoltaic Module Manufacturers in Germany

Algatec Solar AG Product types: photovoltaic modules, monocrystalline silicon photovoltaic modules, polycrystalline silicon photovoltaic modules. Address: Kotschkaer Weg 8, 04932

Performance Investigation of Monocrystalline and Polycrystalline PV

Nov 13, 2024 · Crystalline silicon PV module dominates PV technology worldwide and are constantly emerging with innovative PV designs. Passivated Emitter and Rear Cell PV

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · This study will be useful for future PV LCA practitioners as it comprehensively addresses the potential environmental impact of single-crystalline silicon glass-glass modules

Defect analysis and performance evaluation of photovoltaic modules

Jan 8, 2025 · Abstract This paper presents a defect analysis and performance evaluation of photovoltaic (PV) modules using quantitative electroluminescence imaging (EL). The study

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Single crystalline silicon (also known as monocrystalline silicon) and multi-crystalline silicon (also known as polycrystalline silicon) are two

European Glass-Glass Photovoltaic Modules Are

Sep 23, 2021 · In the study, Fraunhofer ISE calculated the CO2 footprint of six monocrystalline silicon photovoltaic modules. Modules manufactured in China,

Crystalline Silicon Photovoltaic Module Manufacturing

Feb 10, 2020 · Polycrystalline silicon or "polysilicon" is the feedstock used to make monocrystalline- or multicrystalline-silicon ingots, which are then sliced into wafers, fabricated

Monocrystalline VS Polycrystalline Solar PV Modules

Jun 20, 2024 · Choosing between Monocrystalline and Polycrystalline PV modules is a huge dilemma. Read this article to quickly compare the cost, efficiency, and lifespan of the two to

6 FAQs about [German monocrystalline silicon photovoltaic modules]

Can a photovoltaic system be installed in a European location?

"If I want to install a photovoltaic system in a European location with average irradiation values, I have a great influence on its climate friendliness with the choice of my PV modules," explains Dr. Holger Neuhaus, Head of Department for Module Technology at Fraunhofer ISE.

How efficient are monocrystalline wafer-based silicon modules?

In the last 10 years, the efficiency of commercial monocrystalline wafer-based silicon modules increased from about 16% to values over 22%. At the same time, the CdTe module efficiency increased from 9% to 19%. In the laboratory, the best performing modules are based on monocrystalline silicon with 25.4% efficiency.

Are solar panels a viable business model in Germany?

Today residential and small commercial PV systems are often installed together with battery storage and a charging station for electric vehicles. Due to relative high electricity tariffs in Germany, self consumption is the prevailing business model. The installation of balcony solar systems is another growing trend.

Do silicon photovoltaic modules produce less CO2?

In a new study, researchers at the Fraunhofer ISE have calculated that silicon photovoltaic modules manufactured in the European Union produce 40 percent less CO2 than modules manufactured in China.

What is a bifacial solar module?

LONGi launched its mono-PERC modules in 2016, featuring integrated PERC technology on monocrystalline silicon and low light degradation, and its cell efficiency has increased from 21% to 24.06%. Bifacial modules collect solar energy from both the front and back side of the module, increasing the total power output per module.

Are glass-glass PV modules a good choice?

Glass-glass PV modules (b) do not require an aluminum frame and therefore have a lower carbon footprint than PV modules with backsheet (a). Although photovoltaic modules convert sunlight into electricity without producing emissions, PV-generated solar energy does produce CO2 emissions during production, transport and at the end of module life.

Learn More

- Basseterre monocrystalline silicon photovoltaic modules

- Conversion rate of monocrystalline silicon photovoltaic modules

- Flexible monocrystalline silicon photovoltaic panels

- Monocrystalline silicon 660 photovoltaic panel

- Monocrystalline single-sided and bifacial photovoltaic modules

- Small monocrystalline silicon photovoltaic panel

- Thin monocrystalline silicon photovoltaic panels

- Thailand monocrystalline silicon photovoltaic panel manufacturer

- Making monocrystalline silicon photovoltaic panels

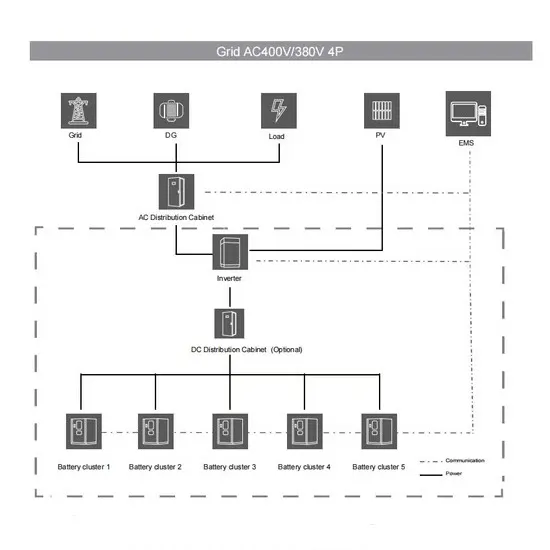

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.