The Pros and Cons of Monocrystalline Solar Panels

5 days ago · Monocrystalline solar panels are made from a single silicon crystal, which makes them the most efficient type of solar panels available. However,

Monocrystalline Solar Panels: How They Work,

Sep 16, 2023 · Monocrystalline solar panels utilize monocrystalline silicon cells to transform sunlight into usable electrical energy. These cells are made from

Flexible Solar Panels (bendable solar panel) Explained: Cost

Jul 23, 2025 · Flexible solar panels (bendable solar panel) are solar modules made using thin-film photovoltaic (PV) materials or specially designed crystalline silicon that allow the panel to bend

The Truth About Flexible Solar Panels: Pros, Cons

Dec 18, 2024 · Flexible solar panels utilize thin-film materials such as amorphous silicon (a-Si), cadmium telluride (CdTe), and copper indium gallium selenide

Flexible Solar Panels: Innovative Technology to

5 days ago · What are flexible solar panels? Silicon wafers make up a typical monocrystalline or polycrystalline solar module. Usually reaching a thickness

SunPower Solar Panels | Solar Products | SunPower Global

2 days ago · SunPower Maxeon solar panels are the highest efficiency panel you can buy with unmatched reliability * Jordan, et. al. Robust PV Degradation Methodology and Application.

Flexible solar panels: Everything you need to know

May 2, 2023 · Flexible solar panels are less efficient than rigid panels but have a wider variety of applications due to their flexibility and thin size (typically 200 micrometers). Recently, organic

Monocrystalline vs. Polycrystalline vs. Thin-Film

Mar 7, 2025 · When it comes to Monocrystalline vs. Polycrystalline vs. Thin-Film Solar Panels, understanding their distinct characteristics and benefits is

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-Film Solar Panels Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous

Flexible Solar Panels: Pros, Cons, and Complete

Jun 20, 2025 · Flexible solar panels —also known as bendable solar panels or solar power flexible panels —are ultra-lightweight photovoltaic modules made

The Best Flexible Solar Panels (2025) | Today''s

Feb 24, 2025 · The DOKIO Semi-Flexible Solar Panel is extremely lightweight at only 0.1 inches in thickness. Incredibly straightforward to install in both

Flexible Solar Panels (bendable solar panel) Explained: Cost

Jul 23, 2025 · As the demand for sustainable and portable energy solutions increases across the world, flexible photovoltaic panels (commonly known as flexible solar panels) have emerged

The Best Flexible Solar Panels

Nov 16, 2024 · Because of their portability, flexible solar panel kits often have built-in power outlets for small appliances. Flexible solar panels come with portable power stations for off

Flexible solar cells based on foldable silicon wafers with

May 24, 2023 · Modules of foldable crystalline silicon solar cells retain their power-conversion efficiency after being subjected to bending stress or exposure to air-flow simulations of a

Amazon : SunPower Accessories : Patio, Lawn & Garden

Jul 18, 2017 · SunPower''s panels are constructed with top-grade, light-weight polymer materials, allowing the for easy transport, installation and panel flexing up to 30 degrees. Made with

What Are Flexible Solar Panels? The Lightweight

Jul 19, 2022 · The conventional solar panels most residential solar companies install are made of monocrystalline silicon solar cells and are rigid rectangles,

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous silicon, deposited onto a

Flexible silicon solar cells with high power-to-weight ratios

Jan 31, 2024 · It is found that the 57-μm flexible and thin solar cell shows the highest power-to-weight ratio (1.9 W g−1) and open-circuit voltage (761 mV) compared to the thick ones.

Flexible silicon solar cells with high power-to-weight ratios

Jan 31, 2024 · A study reports a combination of processing, optimization and low-damage deposition methods for the production of silicon heterojunction solar cells

6 FAQs about [Flexible monocrystalline silicon solar photovoltaic panels]

What is the difference between monocrystalline and flexible solar panels?

For comparison, most standard residential and commercial monocrystalline panels have an efficiency of about 20%. They require a large installation space: Due to their low power output, flexible panels take up a lot of space since you’ll need more panels to generate the same amount of energy as silicon panels.

What are flexible solar panels made of?

Flexible solar panels made of ultra-thin silicon cells have been around for a while. More recently, research at the Massachusetts Institute of Technology has led to advances in organic solar cells. Instead of using silicon as the basis for solar cells, researchers have found a way to use organic materials with graphene electrodes.

Are flexible solar panels better than rigid solar panels?

Flexible solar panels are less efficient than rigid panels but have a wider variety of applications due to their flexibility and thin size (typically 200 micrometers). Recently, organic silicon cells have been used to make flexible solar panels. Given their light weight, flexible solar panels are ideal for portable solar applications.

Are flexible solar panels more durable than crystalline solar panels?

The flexible solar panels are less durable but they are quite easy to install. Currently, in U.S. solar market, two types of flexible solar panels are available. The first type is a thin film. In these panels, the photovoltaic silicon layer is printed on a flexible surface. However, in crystalline solar panels, silicon is sliced into thin sheets.

What makes flexible solar panels unique?

What makes flexible panels unique is their substrate material. Instead of being built on a rigid glass base, the cells are embedded in flexible plastic or metal foils, allowing them to bend and contour to uneven or moving surfaces. 1. Lightweight and Portable One of the biggest benefits of flexible solar panels is their low weight.

What are flexible thin-film solar panels?

Along with traditional mono- and polycrystalline solar panels on a rigid frame, flexible thin-film panels are widely used. The technological process of creating thin-film solar cells formed on flexible substrates is relatively simple, and minimal energy consumption significantly reduces the cost of manufacturing “flexible” solar cells.

Learn More

- Monocrystalline silicon photovoltaic panels solar energy

- Flexible monocrystalline silicon photovoltaic panels

- Production of monocrystalline silicon photovoltaic panels

- Making monocrystalline silicon photovoltaic panels

- Thin monocrystalline silicon photovoltaic panels

- Photovoltaic solar panels vs silicon

- Solar crystalline silicon photovoltaic panels

- Cambodia high power flexible photovoltaic solar panels

- The difference between high and low volts of photovoltaic solar panels

Industrial & Commercial Energy Storage Market Growth

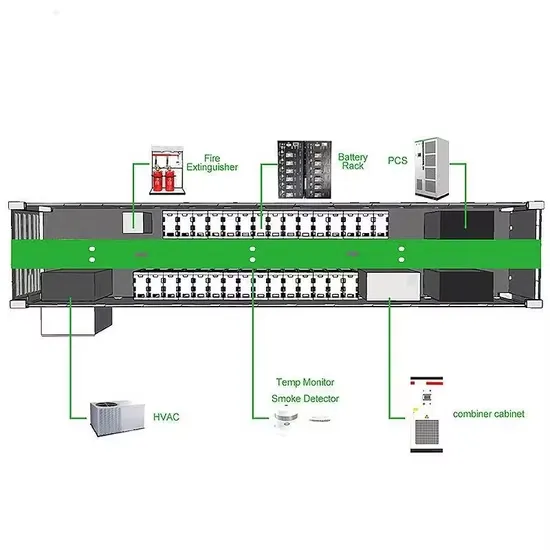

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

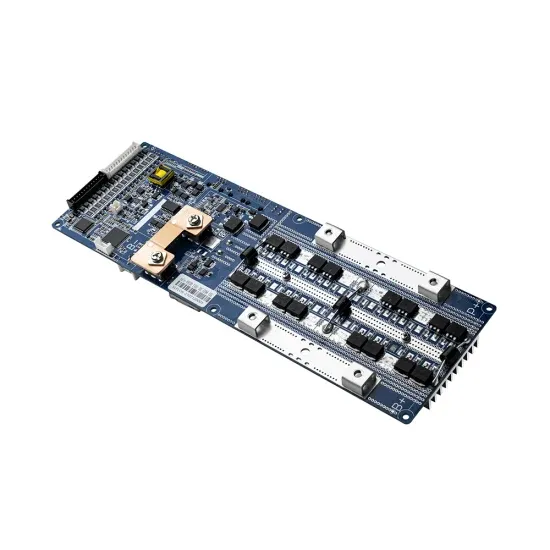

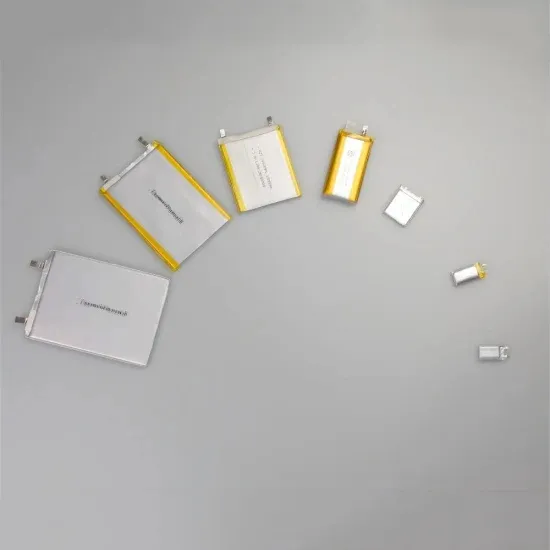

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.