Current status and challenges in silver recovery from End-of

Nov 15, 2024 · Photovoltaic (PV) technology, specifically with crystalline silicon (c-Si) modules, stands out as the predominant means of harnessing solar energy in contemporary times [2].

Thin Film Vs. Crystalline Solar Panels

5 days ago · Thin Film Solar Panels: Thin-film solar cells are primarily useful for utility and large-scale industrial solar installations as they have a lower efficiency rating. A photovoltaic

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-Film Solar Panels Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous

Crystalline Silicon Module

Crystalline silicon or silicon wafer is the dominant technology for manufacturing of PV solar cells. The monocrystalline silicon and polycrystalline silicon are popular for high efficiency solar cells.

A technical review of crystalline silicon photovoltaic module

Oct 1, 2024 · The estimated average lifespan of crystalline silicon solar panels is about 25 years. Still, premature waste through damage to equipment during transportation, installation, natural

Photovoltaic solar panels of crystalline silicon:

Jan 19, 2016 · Photovoltaic panels have a limited lifespan and estimates show large amounts of solar modules will be discarded as electronic waste in a near

Overview of life cycle assessment of recycling end-of-life photovoltaic

Jan 1, 2024 · Technical routes for recycling end-of-life crystalline silicon solar PV panels. (For interpretation of the references to colour in this figure legend, the reader is referred to the Web

What are the solar crystalline silicon panels? | NenPower

Oct 8, 2024 · 1. Solar crystalline silicon panels are popular due to their efficiency and durability, which makes them a preferred choice for many residential and commercial applications. 2.

What''s the Difference Between Silicon Solar

Nov 15, 2024 · Crystalline-silicon solar panels are efficient, reliable, and dominate the solar-panel market. However, new third-gen solar technology could do

Why Silicon is the Most Widely Used Material in

May 15, 2024 · Discover why silicon is used in solar panels as the key material for harvesting clean energy efficiently. Explore its vital role in solar technology.

Life Cycle Assessment of an innovative recycling process for

Nov 1, 2016 · In the last years the interest upon new technologies for the PV panels recycling raised, as proved by the innovative treatments developed by ''Deutsche Solar'' for the recycling

Photovoltaic solar panels of crystalline silicon: Characterization

Photovoltaic panels have a limited lifespan and estimates show large amounts of solar modules will be discarded as electronic waste in a near future. In order to retrieve important raw

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Why Silicon Remains the Top Choice for Solar

Dec 20, 2024 · Over the last five years, the global expansion of photovoltaic (PV) capacity has further driven down the cost of crystalline silicon solar panels to

A comprehensive review on the recycling technology of silicon

Apr 5, 2024 · With the aim of realizing the goals of the Paris Agreement, annual solar power generation on a global scale using silicon PV panels had exceeded 1000 TWh by the end of

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and development efforts that lead to

6 FAQs about [Solar crystalline silicon photovoltaic panels]

What is a crystalline silicon photovoltaic cell?

One of several silicon-based semiconductor products is the crystalline silicon photovoltaic cell. The PV cell is essentially a diode with a semiconductor structure, and during the early stages of the development of solar cells, numerous approaches for crystalline silicon cells were presented on the basis of silicon semiconductor devices.

What is crystalline silicon PV technology?

Photovoltaic technology, also known as solar power, harnesses the sun’s energy to generate electricity through the use of photovoltaic cells. Understanding photovoltaic technology, and in particular, crystalline silicon PV technology is crucial for those seeking to adopt renewable energy solutions.

What is a polycrystalline solar panel?

Solar panels known as polycrystalline or multi-crystalline include many silicon crystals within a single PV cell. The wafers of polycrystalline solar panels are created by melting a number of silicon shards together. The molten silicon vat used to make the polycrystalline solar cells is allowed to cool on the panel itself in this situation.

What are the different types of crystalline silicon PV cells?

There are two types of crystalline silicon PV cells: monocrystalline and polycrystalline. Monocrystalline cells are made from a single crystal of silicon, while polycrystalline cells are made from many smaller crystals.

How are solar PV cells made?

Solar PV cells are primarily manufactured from silicon, one of the most abundant materials on Earth. Silicon is found in sand and quartz. To make solar cells, high purity silicon is needed. The silicon is refined through multiple steps to reach 99.9999% purity. This hyper-purified silicon is known as solar grade silicon.

What is a crystalline solar cell?

The first generation of the solar cells, also called the crystalline silicon generation, reported by the International Renewable Energy Agency or IRENA has reached market maturity years ago . It consists of single-crystalline, also called mono, as well as multicrystalline, also called poly, silicon solar cells.

Learn More

- Photovoltaic crystalline silicon solar panels

- Flexible monocrystalline silicon solar photovoltaic panels

- Photovoltaic solar panels vs silicon

- Specifications of photovoltaic crystalline silicon panels

- Monocrystalline silicon photovoltaic panels solar energy

- Maximum power of solar panels and photovoltaic panels

- Solar photovoltaic panels in rural areas

- Household solar foldable photovoltaic panels

- The difference between high and low volts of photovoltaic solar panels

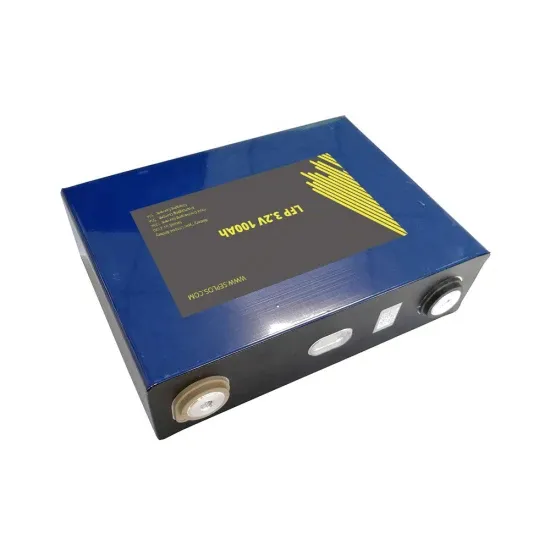

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.