Monocrystalline silicon photovoltaic panel specifications

What are monocrystalline solar panels? Monocrystalline solar panels are a type of solar panel that has gained popularity in recent years due to their high efficiency and durability. They are made

Technical Specifications of Polycrystalline Photovoltaic

The surface of these solar cells resembles a mosaic which comes under polycrystalline solar panel specifications. These solar panels are square in form and have a brilliant blue color due

Monocrystalline silicon solar energy specifications

Download scientific diagram | Specifications of mono-crystalline silicon PV modules at STC from publication: Modeling a Simple Single-phase Grid-connected Photovoltaic System...

Solar Photovoltaic Glass Panel Specifications

When selecting PV glass for solar panels,several key specifications need to be considered to ensure optimal performance and compatibility with project requirements. The thicknessof PV

Performance analysis of mono crystalline, poly crystalline and

Dec 1, 2021 · PV materials fall into three categories: crystallized silicon, thin film technology, and new emerging technologies as shown in Fig. 1 (a). Silicon is one of the most prevalent

Dimensions and specifications of crystalline silicon

Most modules use wafer-based crystalline silicon cells or thin-film cells. The manufacturing specifications on solar panels are obtained under Crystalline silicon solar cells are today''''s

Standards for PV Modules and Components Recent

Oct 3, 2013 · The following is a list of the IEC standards on PV modules (and devices) published by TC82. The list includes details on which edition is now current and what year that edition

Specifications and models of polycrystalline silicon

Sep 30, 2020 · silicon can also be obtained during silicon manufacturing processes. Polycrystalline cells have an efficiency that varies from 12 to 21%. These solar cells are

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Single crystalline silicon (also known as monocrystalline silicon) and multi-crystalline silicon (also known as polycrystalline silicon) are two

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

Feb 3, 2021 · The PV Module should be under the Indigenous / DCR (Domestic Content Requirement) category (Based on the specific requirement). The PV modules shall conform to

Solar Panel Products

Oct 13, 2015 · Solar Electric is a supplier of the highest quality European manufactured High Yield PV Modules which are in-house designed and manufactured in state of the art MCS Certified

Specifications and models of polycrystalline silicon

silicon can also be obtained during silicon manufacturing processes. Polycrystalline cells have an efficiency that varies from 12 to 21%. These solar cells are manufactured by recycling

Crystalline silicon photovoltaic panel component specifications

Jun 21, 2021 · As the photovoltaic (PV) industry continues to evolve, advancements in Crystalline silicon photovoltaic panel component specifications have become critical to optimizing the

Analysis of specifications of solar photovoltaic panels

May 1, 2022 · Parameters of photovoltaic panels (PVPs) is necessary for modeling and analysis of solar power systems. The best and the median values of the main 16 parameters among

Monocrystalline silicon photovoltaic panel specifications

Unlike monocrystalline and polycrystalline solar panels, thin-film solar panels are manufactured using photovoltaic substances which include Amorphous silicon (a-Si), copper

Monocrystalline silicon photovoltaic panel specifications

Mono-crystalline silicon photovoltaic cells under different solar irradiation levels. the modelling and simulation of the PV module are based on the specifications of the PV

Crystalline silicon solar panels photovoltaic

The International Technology Roadmap for Photovoltaic (ITRPV) predicts an upward trend for the shares of crystalline silicon (c-Si) bifacial PV cells and modules in the global PV market in the

Photovoltaic carbon crystal panel specifications

silicon represented 96% of global solar shipments in 2022,making it the most common absorber materialin today''s solar modules. The remaining 4% consists of other materials,mostly

Specifications and models of Chint photovoltaic panels

A PV combiner box is the key to housing a joint connection between various panels and the entire system''''s inverter. Think of this box as the heart of a seamless solar energy solution. What is

APPENDIX 2 TECHNICAL SPECIFICATIONS FOR SOLAR

May 31, 2024 · Solar-PV System Specifications This section covers the specification of works for the abstraction of water from the source using solar energy related equipment here collectively

Monocrystalline silicon photovoltaic panel specification

Monocrystalline solar panels are a type of solar panel that has gained popularity in recent years due to their high efficiency and durability. They are made from a single crystal of silicon, which

Polycrystalline Solar Panel: Features, Working

Jun 15, 2024 · Polycrystalline or multi crystalline solar panels are solar panels that consist of several crystals of silicon in a single PV cell. Several fragments of

Monocrystalline silicon photovoltaic panel specifications

What are monocrystalline solar panels? Monocrystalline solar panels are made from single-crystal silicon,resulting in their distinctive dark black hue. This uniform structure,with fewer grain

Building Integrated Photovoltaics

Oct 12, 2021 · If section 263100 is used to spec the PV Glass system, it should also be mentioned in section 088000 Glass and Glazing. Otherwise glazing contractors may not bid the

Crystalline Silicon Photovoltaics

Mono-crystalline silicon, produced by slicing wafers from a high-purity single crystal ingot Multi-crystalline silicon, made by sawing a cast block of silicon first into bars and then into wafers

Monocrystalline silicon photovoltaic panel specifications

Monocrystalline silicon can be prepared as: It can also be doped by adding other elements such as boron or phosphorus. Monocrystalline silicon is used to manufacture high-performance

Crystalline silicon photovoltaic panel component

Crystalline silicon photovoltaic (PV) cells are used in the largest quantity of all types of solar cells on the market, representing about 90% of the world total PV cell production

6 FAQs about [Specifications of photovoltaic crystalline silicon panels]

What are crystalline silicon PV modules?

This article will discuss an overview of Crystalline Silicon PV Modules. Photovoltaic (PV) cells, commonly referred to as solar cells, are assembled into a PV module or solar PV module. PV modules (also known as PV panels) are linked together to form an enormous array, called a PV array, to meet a specific voltage and current need.

What is crystalline silicon photovoltaics?

Crystalline silicon photovoltaics is the most widely used photovoltaic technology. Crystalline silicon photovoltaics are modules built using crystalline silicon solar cells (c-Si). These have high efficiency, making crystalline silicon photovoltaics an interesting technology where space is at a premium.

What are crystalline silicon solar cells?

They’re modules made from crystalline silicon solar cells produced in the microelectronics industry, which is why they’re called crystalline silicon photovoltaics. There are many applications where space is limited, and crystalline silicon solar cells provide a high-efficiency level.

Are polycrystalline silicon PV modules more efficient than single crystalline silicon?

Despite having lower conversion efficiencies, polycrystalline silicon PV modules are still more efficient than single crystalline silicon PV modules, averaging around 10-12 percent. The most extensively used photovoltaic technology is crystalline silicon photovoltaics.

What are polycrystalline and monocrystalline silicon photovoltaics?

Polycrystalline and monocrystalline silicon photovoltaics are two types of crystalline silicon cells. Polycrystalline silicon cells are created by sawing cast silicon into bars and then cutting them into wafers. If playback doesn't begin shortly, try restarting your device.

What are the parameters of photovoltaic panels (PVPS)?

Parameters of photovoltaic panels (PVPs) is necessary for modeling and analysis of solar power systems. The best and the median values of the main 16 parameters among 1300 PVPs were identified. The results obtained help to quickly and visually assess a given PVP (including a new one) in relation to the existing ones.

Learn More

- Photovoltaic crystalline silicon solar panels

- Solar crystalline silicon photovoltaic panels

- Photovoltaic panels silicon wafers and batteries

- There are several specifications for the width of photovoltaic panels

- Flexible monocrystalline silicon solar photovoltaic panels

- Monocrystalline silicon high power photovoltaic panels

- Photovoltaic solar panels vs silicon

- Production of monocrystalline silicon photovoltaic panels

- There are several models and specifications of photovoltaic panels

Industrial & Commercial Energy Storage Market Growth

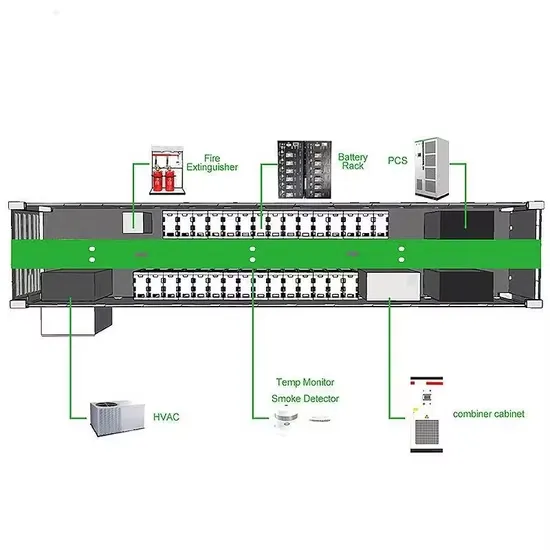

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

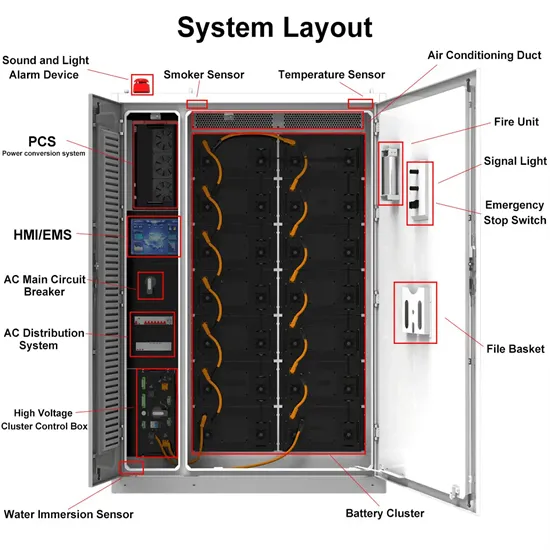

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.