The current status of silicon wafers and batteries in the

The effective management of silicon kerf waste produced from silicon wafer cutting processes of photovoltaic industry is of great significance for environmental protection and resources recycle

Non-destructive recovery of silicon wafers from waste photovoltaic

Jul 19, 2025 · The continuous increase of waste photovoltaic (PV) modules poses a great challenge to global environmental protection and human health. As the main body of waste PV

Are silicon wafers photovoltaic panels

By interacting with our online customer service, you''ll gain a deep understanding of the various Are silicon wafers photovoltaic panels featured in our extensive catalog, such as high

Sustainable Strategies for Crystalline Solar Cell

Jul 7, 2024 · The classification of PV recycling companies based on various components, including solar panels, PV glass, aluminum frames, silicon solar

Thermostatic pyrolysis decapsulation and pollution control

The rapid expansion of photovoltaics is anticipated to result in a substantial accumulation of waste crystalline silicon photovoltaics (c-Si PV) panels that composed of glass, silicon wafers, and

New Study Explores Reusing Solar Panel Silicon for High

Apr 15, 2025 · In a recently published study, UVA Environmental Institute faculty affiliates Gary Koenig and Mool Gupta, alongside co-authors, explore how silicon from decommissioned solar

Photovoltaic recycling: enhancing silicon wafer recovery

Apr 30, 2024 · Through investigation, this research demonstrates the feasibility and cost-effectiveness of silicon wafer recovery from damaged silicon solar panels. As photovoltaic

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

End‐of‐Life Photovoltaic Recycled Silicon: A

May 5, 2021 · Advanced repurpose processes are developed to turn photovoltaic (PV) waste into the high-value circular energy materials. By recycling silicon

Solar Wafers: The Building Blocks of Photovoltaic

Apr 5, 2024 · Solar panels mainly use monocrystalline or polycrystalline silicon for today''s photovoltaic technology. Monocrystalline silicon wafers show excellent

Recovery of nano-structured silicon from end-of-life photovoltaic

Herein, we demonstrate a potential end-of-life management option for photovoltaic (PV) panels, representing a step toward producing greener and more energy-efficient Si for batteries.

Silicon wafers for solar photovoltaic panels

About Silicon wafers for solar photovoltaic panels In the PV industry, the production chain from quartz to solar cells usually involves 3 major types of companies focusing on all or only parts

Resource utilization of waste solar photovoltaic panels for

Feb 1, 2025 · With the exponential growth of global photovoltaic (PV) installed capacity, the quantity of discarded PV modules continues to rise. This study innovatively explored the

Simplified silicon recovery from photovoltaic waste enables

Aug 1, 2023 · This approach led to an impressive recovery rate of 98.9% with a high purity of 99.2%, as determined by X-ray fluorescence and Inductively-coupled plasma optical emission

Recycling process promises ''better than new''

Jun 16, 2022 · Scientists in China have developed a new recycling process for PV modules that can recover intact silicon cells from end-of-life products, and

Recovery of Nano-Structured Silicon from End-Of-Life Photovoltaic

Mar 27, 2020 · Request PDF | Recovery of Nano-Structured Silicon from End-Of-Life Photovoltaic Wafers with Value-Added Applications in Lithium-Ion Battery | Millions of residential and

Photovoltaic recycling: enhancing silicon wafer recovery

Apr 30, 2024 · Particularly, the focus lies on the advantageous recovery of high-value silicon over intact silicon wafers. Through investigation, this research demonstrates the feasibility and cost

Solar Panel Manufacturing Process: Step-by-Step Guide

Apr 12, 2025 · The key components in solar PV manufacturing include silicon wafers, solar cells, PV modules, and solar panels. Silicon is the primary material used, which is processed into

What Is a Silicon Wafer for Solar Cells?

P-type (positive) and N-type (negative) silicon wafers are the essential semiconductor components of the photovoltaic cells that convert sunlight into electricity in over 90% of solar

$2.8M USDOE funding for project that would recycle silicon

Sep 2, 2023 · A US consortium is investigating recycling silicon wafers from PV panels for use in batteries for electric vehicles, claiming the recycled material can also cut battery costs, and the

What you need to know about polysilicon and

Oct 13, 2021 · Polysilicon, a high-purity form of silicon, is a key raw material in the solar photovoltaic (PV) supply chain. To produce solar modules, polysilicon is

The current status of silicon wafers and batteries in the

Germanium is sometimes combined with silicon in highly specialized -- and expensive -- photovoltaic applications. However, purified crystalline silicon is the photovoltaic

6 FAQs about [Photovoltaic panels silicon wafers and batteries]

What are silicon wafer-based photovoltaic cells?

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow’s rigid, flexible, and portable solar panels use the highest quality monocrystalline silicon solar cells, offering industry-leading efficiency for residential on-grid and off-grid applications.

Which solar panels use wafer based solar cells?

Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells. The only alternatives to wafer-based solar cells that are commercially available are low-efficiency thin-film cells. Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells.

Are recycled silicon wafers suitable for solar cells?

The photovoltaic (PV) industry uses high-quality silicon wafers for the fabrication of solar cells. PV recycled silicon, however, is not suitable for any application without further purification, as it contains various impurities.

Do silicon wafer-based solar cells produce more electricity than thin-film solar cells?

Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells. It’s helpful to note that efficiency has a specific meaning when applied to solar cells and panels. It’s a spec that measures the wattage produced per square meter (m²) of photovoltaic material exposed to peak sunlight.

Do thin film solar panels use wafers?

Thin-film solar panels do not use wafers but are highly inefficient and only used in rare circumstances. Over 90% of solar panels use silicon wafers. What Is the Difference Between a Solar Cell and a Solar Wafer?

Can silicon wafers be recovered from damaged solar panels?

Particularly, the focus lies on the advantageous recovery of high-value silicon over intact silicon wafers. Through investigation, this research demonstrates the feasibility and cost-effectiveness of silicon wafer recovery from damaged silicon solar panels.

Learn More

- Production of monocrystalline silicon photovoltaic panels

- How many batteries should be selected for photovoltaic panels

- Flexible monocrystalline silicon solar photovoltaic panels

- Monocrystalline silicon photovoltaic panels solar energy

- Are monocrystalline silicon photovoltaic panels afraid of corrosion

- Flexible monocrystalline silicon photovoltaic panels

- Flexible photovoltaic panels connected to family car batteries

- Photovoltaic solar panels vs silicon

- How many batteries are used for 10 square meters of photovoltaic panels

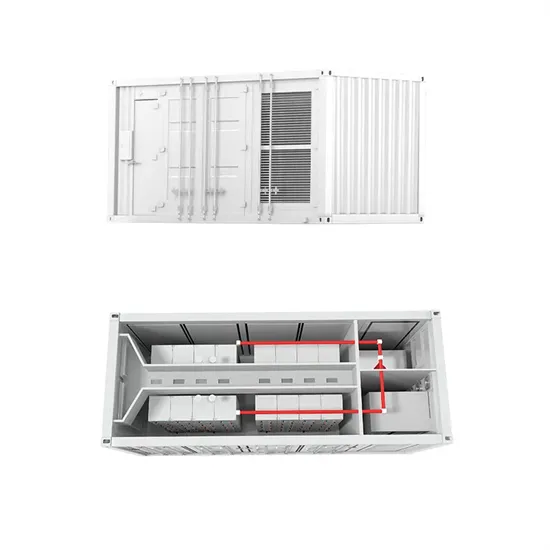

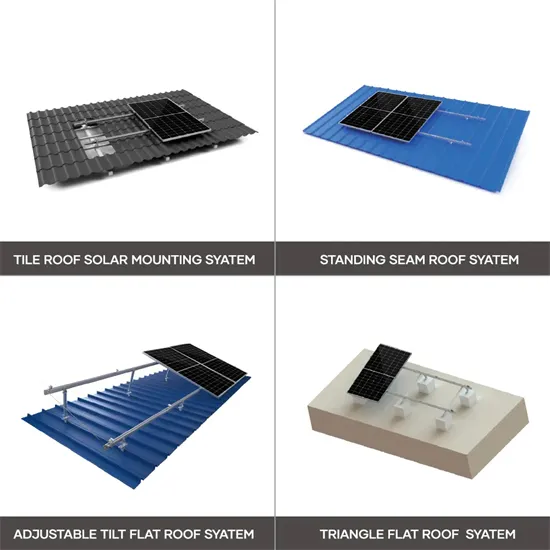

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.