A method to recycle silicon wafer from end-of-life photovoltaic module

Apr 1, 2017 · A method to recycle silicon wafer from end-of-life photovoltaic module and solar panels by using recycled silicon wafers Jeongeun Shin a, Jongsung Park b, Nochang Park a

Free-standing ultrathin silicon wafers and solar cells through

May 7, 2024 · Here, authors present a thin silicon structure with reinforced ring to prepare free-standing 4.7-μm 4-inch silicon wafers, achieving efficiency of 20.33% for 28-μm solar cells.

A method to recycle silicon wafer from end-of-life photovoltaic module

Apr 1, 2017 · We investigated a new method for reclaiming Si wafers from EoL PV modules by applying etching paste and for the manufacture of Pb-free solar panels. Ag and Al metal

The solar cell wafering process

May 21, 2024 · The multi-wire sawing technique used to manufacture wafers for crystalline silicon solar cells, with the reduction of kerf loss currently representing about 50% of the silicon,

Recycling process promises ''better than new''

Jun 16, 2022 · Scientists in China have developed a new recycling process for PV modules that can recover intact silicon cells from end-of-life products, and

Solar Photovoltaic Manufacturing Basics

4 days ago · Cell Fabrication – Silicon wafers are then fabricated into photovoltaic cells. The first step is chemical texturing of the wafer surface, which removes

What Are Solar Wafers?

Mar 1, 2025 · The production of high-quality solar wafers is vital for ensuring the efficiency and longevity of solar pv modules. The production of wafers involves highly pure (99.9999999%

Photovoltaic recycling: enhancing silicon wafer recovery

Apr 30, 2024 · The recovery of silicon wafers is integral to the sustainable production of solar panels, as these panels heavily rely on high-quality silicon substrates to efficiently convert

Solar Silicon Wafer Market | Global Market Analysis Report

Aug 11, 2025 · Within the solar photovoltaic module components market, silicon wafers capture 28–30% of component-level value, since wafer quality and size directly influence panel

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · This includes the basic principles of manufacturing c-Si wafers (preparing pure silicon, fabrication of both single-crystal and multicrystalline ingots, and wafering), and the

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Historical market projections and the future of silicon

Dec 16, 2023 · The data in the reports are gathered via questionnaires sent to individuals and companies operating in all sec-tors of the PV industry up to the creation of the PV module.

Manufacturing of Silicon Solar Cells and Modules

Jun 13, 2023 · To get from cell making to module making requires proper preparation of pristine wafers to be physically and electrically connected in series to achieve the rated output of a PV

Solar Cell Production: from silicon wafer to cell

May 21, 2024 · In this paper, the basic principles and challenges of the wafering process are discussed. The multi-wire sawing technique used to manufacture wafers for crystalline silicon

Flexible solar cells based on foldable silicon wafers with

May 24, 2023 · Modules of foldable crystalline silicon solar cells retain their power-conversion efficiency after being subjected to bending stress or exposure to air-flow simulations of a

Photovoltaic Cell (Polysilicon/ Wafers)

Feb 8, 2024 · Polycrystalline modules are made from cells composed of multiple small silicon crystals which makes them cheaper to produce though they are slightly less efficient than

Fracture strength analysis of large-size and thin photovoltaic

Nov 8, 2024 · Sawing monocrystalline silicon (mono-Si) brick into mono-Si wafers is the primary mechanical process to produce PV solar cell substrates. The mature application of

Photovoltaics Manufacturing, Polysilicon | Solar Power

PV manufacturing includes three distinct processes: 1. Manufacturing silicon (polysilicon or solar-grade), 2. wafers (mono- or polycrystalline) and 3. cells and modules (crystalline and thin-film).

Fabricating Different Types of Photovoltaic Cells

Jun 2, 2021 · The manufacture of crystalline silicon modules involves fabricating silicon wafers, transforming the wafers into cells, and assembling cells into

6 FAQs about [Photovoltaic cell silicon wafers and module silicon wafers]

Which solar panels use wafer based solar cells?

Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells. The only alternatives to wafer-based solar cells that are commercially available are low-efficiency thin-film cells. Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells.

What are silicon wafer-based photovoltaic cells?

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow’s rigid, flexible, and portable solar panels use the highest quality monocrystalline silicon solar cells, offering industry-leading efficiency for residential on-grid and off-grid applications.

Do thin-film solar cells use silicon wafers?

Thin-film solar cells don’t use silicon wafers but are highly inefficient and rarely used. Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology.

Are silicon wafer-based solar cells a good investment?

Silicon (Si) wafer-based solar cells currently account for about 95% of the photovoltaic (PV) production and remain as one of the most crucial technologies in renewable energy. Over the last four decades, solar PV systems have seen a staggering cost reduction due to much reduced manufacturing costs and higher device efficiencies.

Can silicon wafers be used as a starting material for solar cells?

9.4.2.2. PERT, TOPCon, and Bifacial Cells Phosphorous-doped N-type silicon wafers retain lifetimes on the order of milliseconds under the same stresses and therefore can be used as a starting material for high-efficient solar cells.

Why are wafer-based solar cells important?

There are multiple reasons why wafer-based solar cells are the essential component in over 90% of photovoltaic panels and other modules sold worldwide. Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells.

Learn More

- Baku Photovoltaic Cell Module Project

- Amorphous silicon photovoltaic cell components

- Photovoltaic cell module auxiliary equipment

- Crystalline silicon cell photovoltaic modules

- Are thin-film photovoltaic panels made of single-crystal silicon

- Thin monocrystalline silicon photovoltaic panels

- Accra monocrystalline silicon photovoltaic panel charging

- Huawei South Africa Photovoltaic Module Project

- Venezuela photovoltaic module prices

Industrial & Commercial Energy Storage Market Growth

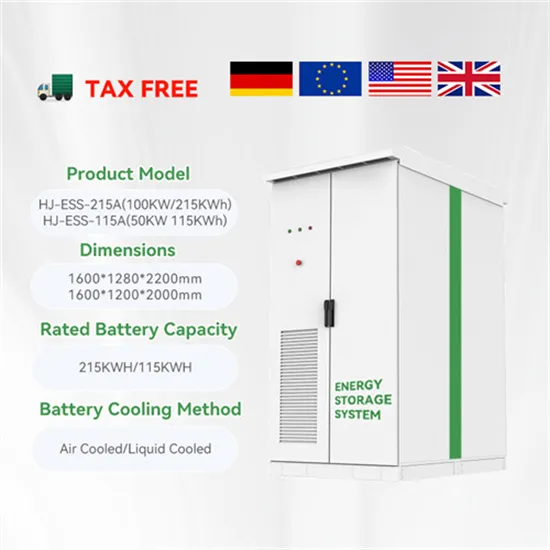

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.