Research and development priorities for silicon photovoltaic module

Jul 13, 2020 · The increasing deployment of photovoltaic modules poses the challenge of waste management. Heath et al. review the status of end-of of-life management of silicon solar

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The solar photovoltaics (PV) market has been booming to meet the global energy demand and to reduce the carbon emissions from energy production. Among all the PV

High-Efficiency Crystalline Photovoltaics | Photovoltaic

Apr 3, 2025 · High-Efficiency Crystalline Photovoltaics NREL is working to increase cell efficiency and reduce manufacturing costs for the highest-efficiency photovoltaic (PV) devices involving

A technical review of crystalline silicon photovoltaic module

Oct 1, 2024 · It dwells deep into the current recycling processes available for crystalline silicon (c-Si) solar panels. It explores the composition of PV modules and provides a detailed analysis of

Crystalline Silicon Solar Cells and Modules

Aug 4, 2010 · A new approach in solar cell module interconnection technique resulting in 5-10% higher PV module power output. Presented at the IEEE 4th World Conference on Photovoltaic

Crystalline Silicon PV Module Technology

Jan 1, 2013 · Crystalline silicon module technology aims to turn solar cells into safe and reliable products, while maximizing efficiency. The chapter highlights fundamental challenges

PV cells and modules

Sep 23, 2020 · At the same time, the current cost of crystalline silicon modules is lower than the cost of modules from other materials due to the large-scale production of silicon feedstock,

Review of c-Si PV module recycling and industrial feasibility

Jan 21, 2025 · Abstract As solar energy emerges as a pivotal renewable energy source, the environmental challenge of end-of-life photovoltaic (PV) module disposal intensifies. This

The research progress on recycling and resource utilization

Jun 15, 2024 · The internal structure of crystalline silicon photovoltaic modules resembles a five-layer sandwich, consisting, from top to bottom, of tempered glass, EVA, solar cells, another

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Single crystalline silicon (also known as monocrystalline silicon) and multi-crystalline silicon (also known as polycrystalline silicon) are two

Recovery of complete crystalline silicon cells from waste crystalline

Jul 7, 2025 · Implications: In this study "Recovery of complete crystalline silicon cells from waste crystalline silicon photovoltaic modules," a new process combining organic solvent method

Photovoltaic (PV) Module Technologies: 2020

Nov 2, 2021 · Technologies based on crystalline silicon (c-Si) dominate the current PV market, and their MSPs are the lowest; the figure only shows the MSP for monocrystalline monofacial

Advances in module interconnection technologies for

May 21, 2024 · Abstract In the evolution towards higher cell efficiencies, new cell concepts (two-sided and back contacted) have been introduced and for each of these concepts, new module

Crystalline silicon solar cell with an efficiency of 20.05 %

Oct 15, 2024 · Crystalline silicon solar cell with an efficiency of 20.05 % remanufactured using 30 % silicon scraps recycled from a waste photovoltaic module

Crystalline Silicon Terrestrial Photovoltaic Cells

4 days ago · Executive Summary and standard that applies to photovoltaic (PV) cells. Many PV module manufacturers depend on third party solar cell manufacturers for their supply of silicon

Crystalline Silicon Solar Cells and Modules

Dec 21, 2010 · This chapter contains sections titled: Introduction Crystalline Silicon as a Photovoltaic Material Crystalline Silicon Solar Cells Manufacturing Process Variations to the

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and development efforts that lead to

A promising method for the liberation and separation of solar cells

Oct 15, 2023 · Abstract Reasonable and efficient recycling of waste crystalline silicon (c-Si) photovoltaic (PV) modules benefits environmental protection and resource conservation. The

Advances in crystalline silicon solar cell technology for

Jul 22, 2010 · Crystalline silicon PV cells are the most popular solar cells on the market and also provide the highest energy conversion efficiencies of all commercial solar cells and modules.

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The workhorse of present PVs is crystalline silicon (c-Si) technology; it covers more than 93% of present production, as processes have been optimized and costs consistently

The research progress on recycling and resource utilization

Jun 15, 2024 · Proposes PV subsidy policies and dynamic standard adjustments. The exponential growth in global photovoltaic installations has led to a continuous increase in photovoltaic (PV)

A review of interconnection technologies for improved crystalline

Sep 15, 2015 · The identification, adoption and utilisation of reliable interconnection technology to assembly crystalline silicon solar cells in photovoltaic (PV) module are critical to ensure that

Status and perspectives of crystalline silicon

Jul 27, 2021 · In this Review, we survey the key changes related to materials and industrial processing of silicon PV components. At the wafer level, a strong reduction in polysilicon cost

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · Understanding photovoltaic technology, and in particular, crystalline silicon PV technology is crucial for those seeking to adopt renewable energy

6 FAQs about [Crystalline silicon cell photovoltaic modules]

What are crystalline silicon photovoltaic modules?

The Crystalline silicon photovoltaic modules are made by using the silicon crystalline (c-Si) solar cells, which are developed in the microelectronics technology industry. The PV solar panels are composed of these solar cells as part of a photovoltaic system to produce solar energy from sunlight.

What are crystalline silicon solar cells?

Crystalline silicon solar cells are today’s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This Review discusses the recent evolution of this technology, the present status of research and industrial development, and the near-future perspectives.

What is a monocrystalline silicon solar module?

Monocrystalline silicon represented 96% of global solar shipments in 2022, making it the most common absorber material in today’s solar modules. The remaining 4% consists of other materials, mostly cadmium telluride. Monocrystalline silicon PV cells can have energy conversion efficiencies higher than 27% in ideal laboratory conditions.

What are polycrystalline and monocrystalline silicon photovoltaics?

Polycrystalline and monocrystalline silicon photovoltaics are two types of crystalline silicon cells. Polycrystalline silicon cells are created by sawing cast silicon into bars and then cutting them into wafers. If playback doesn't begin shortly, try restarting your device.

What is a crystalline silicon module?

Crystalline silicon module consists of individual PV cells connected together by soldering and encapsulated between a transparent front cover, usually glass and weatherproof backing material, usually plastic. You might find these chapters and articles relevant to this topic.

Are polycrystalline silicon PV modules more efficient than single crystalline silicon?

Despite having lower conversion efficiencies, polycrystalline silicon PV modules are still more efficient than single crystalline silicon PV modules, averaging around 10-12 percent. The most extensively used photovoltaic technology is crystalline silicon photovoltaics.

Learn More

- Parallel connection of photovoltaic cell modules

- Photovoltaic cell silicon wafer assembly

- Kosovo crystalline silicon photovoltaic panel manufacturer

- Algerian crystalline silicon photovoltaic curtain wall

- Specifications of photovoltaic crystalline silicon panels

- Tbilisi crystalline silicon photovoltaic curtain wall

- Baku Photovoltaic Cell Module Project

- Subsidy price of photovoltaic modules in Hamburg Germany

- Botswana export tariffs on photovoltaic modules

Industrial & Commercial Energy Storage Market Growth

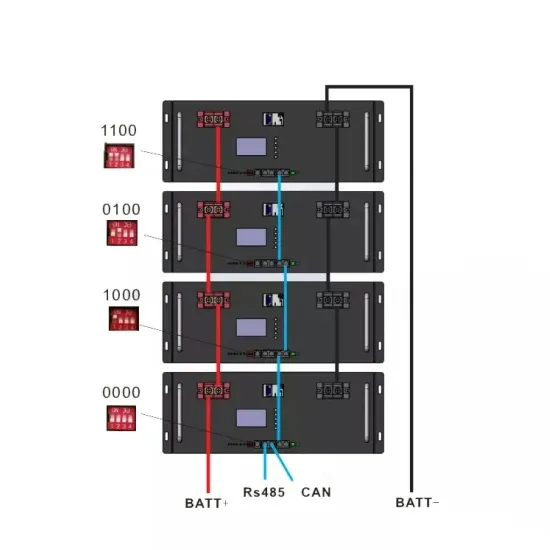

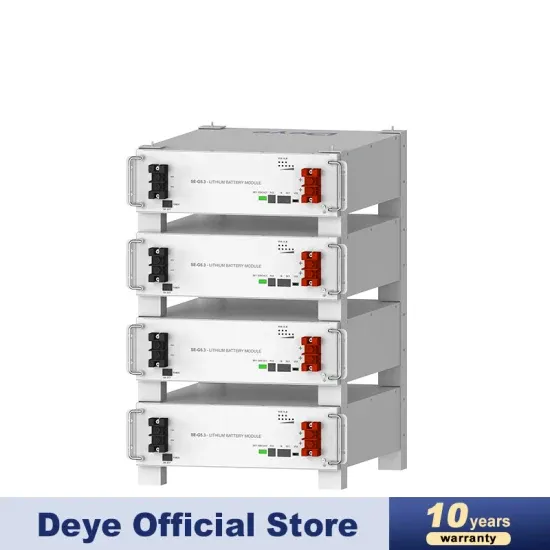

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.