Abstract -The performance of a photovoltaic (PV) array is

Jan 9, 2016 · Each PV module considered in this paper 24-PV cells connected as 2 cells in series, and 12 such series are connected in parallel. The model diagram of parallel connected solar

Modelling series and parallel combinations of mismatched solar PV

Oct 1, 2024 · The rule when connecting non-identical PV panels is to match maximum-power currents when connecting in series and to match maximum-power voltages when connecting

Are Solar Cells Connected In Series Or Parallel?

Jan 9, 2023 · If solar modules are connected in parallel, the positive terminal of one module is connected to the positive terminal of another module, which increases the amperage of the

PV Activity 1: Series and Parallel PV Cell Connections©

Oct 19, 2021 · To teach how to measure the current and voltage output of photovoltaic cells. To investigate the difference in behavior of solar cells when they are connected in series or in

COMPARATIVE ANALYSIS OF I-V & P-V

Aug 7, 2016 · The efficiency of PV array invariably depends upon temperature which in turn is dependent on radiation. This paper focuses mainly on comparison of the experimentation

Chapter Number 3.0 Solar PV modules Explained in detail

Mar 29, 2023 · A solar PV module is a collection of solar cells, mainly connected in series. These combinations of Solar Cell provide higher power than a single solar cell. The PV modules are

Guide to Solar Panel Parallel vs Series Wiring

Feb 15, 2022 · In this article, you''ll learn the basics of series and parallel circuits in electricity as they pertain to solar energy. This discussion will include

Parallel connection of photovoltaic cells and modules

The behaviour of a parallel connection of photovoltaic cells will now be discussed by an example involving two parallel-connected photovoltaic cells. Figure 4.3 shows I-U curves of two

Photovoltaic Panels Parallel vs. Series Connection

Dec 5, 2023 · Parallel connection of photovoltaic panels is used primarily in low-voltage installations, where each module has a separate inverter. This solution

Module configurations in photovoltaic system: A review

Jan 1, 2017 · The various solar energy applications offer clean, environment friendly and exhaustive energy resources to human being. Solar system directly converts the sunlight

Modeling, simulation and performance analysis of solar PV

Nov 1, 2018 · In series connection, the PV array current is same as module current or cell current and the array voltage is equivalent to sum of the voltages of the individual PV modules.

Solar Panel Wiring Guide: How to Connect Solar

Jul 24, 2025 · Solar panel connection is a key part of any photovoltaic system, determining how solar panels deliver power to the rest of the system. Installers

Solar Panel Wiring: Connecting Solar Panels in

Dec 6, 2024 · The connection of solar panels is an important phase in the design of a photovoltaic system, as it directly affects the system''s performance and

Electrical performance of a fully reconfigurable series-parallel

Dec 8, 2023 · In this work, we analyse the outdoor performance of a full-scale prototype of a series-parallel photovoltaic module with six reconfigurable blocks.

Photovoltaic Module Interconnection Modified to

Jan 2, 2018 · PV cell convert solar energy to electricity when exposed to sunlight. In order to get required amount of current (Ampere) and voltage (volts) many PV cells are interconnected into

Solar in Series and Parallel | PDF | Solar Panel

Nov 6, 2024 · A solar photovoltaic array connects multiple solar modules in series and parallel configurations to produce larger voltages and currents needed for

How to Connect Solar Panels in Series and Parallel

Mar 6, 2023 · In this post we will study how to connect solar panels in series and parallel and also learn how to calculate solar panels in series and parallel.

Modelling and Output Power Evaluation of Series

Dec 15, 2018 · PV module models have evolved to include detailed parameters and even multiple piecewise linear regions or better accuracy. However, most have focused on modeling a

Solar Cells : Series and Parallel Connections of SOlar cells Lab

Solar cells in series are termed string. Because solar cells are not perfectly identical, the total current flowing through a string is equal to the lowest value of the solar cell. Figure 1: Solar

DEPARTMENT OF ELECTRICAL AND ELECTRONICS

Feb 21, 2022 · I-V AND P-CHARACTERISTICS WITH SERIES AND PARALLEL COMBINATION OF MODULES AIM :To demonstrate the I-V and P-V characteristics of series and parallel

6 FAQs about [Parallel connection of photovoltaic cell modules]

How to connect solar panels in parallel?

In order to connect solar panels in parallel, you will have to connect the positive (+) terminals of all the solar panels together and the negative (-) terminals together. The total voltage of the solar panel array will be the same as that of a single solar panel, while the current will be the sum of the currents of each solar panel.

What happens if you connect solar panels in parallel?

When you connect solar panels in parallel, you connect the positive (+) terminals of all the solar panels together and the negative (-) terminals together. The total voltage of the array will be the same as that of a single solar panel, while the current will be the sum of the currents of each solar panel.

How are PV modules connected in series and parallel?

In large PV plants first, the modules are connected in series known as “PV module string” to obtain the required voltage level. Then many such strings are connected in parallel to obtain the required current level for the system. The following figures shows the connection of modules in series and parallel.

How are solar panels connected?

Engineers also connect solar panels in a series-parallel configuration. Several panels are first wired together in series to form strings of panels (for instance, three strings of solar panels featuring two panels connected in series would make up a total of six solar panels).

What is a solar PV module array?

Such a connection of modules in a series and parallel combination is known as “Solar Photovoltaic Array” or “PV Module Array”. A schematic of a solar PV module array connected in series-parallel configuration is shown in figure below. Solar Module Cell: The solar cell is a two-terminal device.

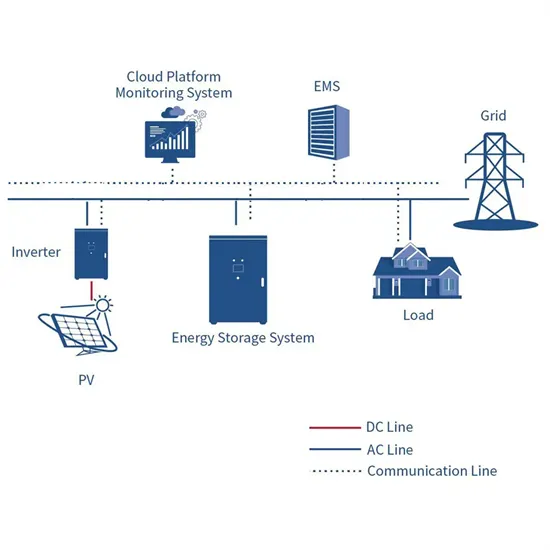

Can solar panels be connected in a photovoltaic system?

The connection of solar panels in a photovoltaic system can be in series or in parallel. Discover the main differences and installation methods The connection of solar panels is an important phase in the design of a photovoltaic system, as it directly affects the system’s performance and overall efficiency.

Learn More

- Crystalline silicon cell photovoltaic modules

- Photovoltaic panels series and parallel connection

- Glass the main material of photovoltaic modules

- Photovoltaic module cell decay rate

- Perovskite photovoltaic cell components

- Vienna double-glass photovoltaic modules

- Photovoltaic cell independent inverter

- Photovoltaic cell shingled assembly

- Voltage of four photovoltaic panels in parallel

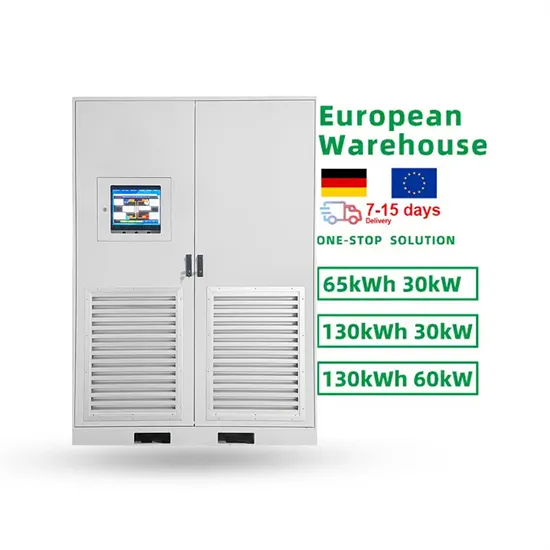

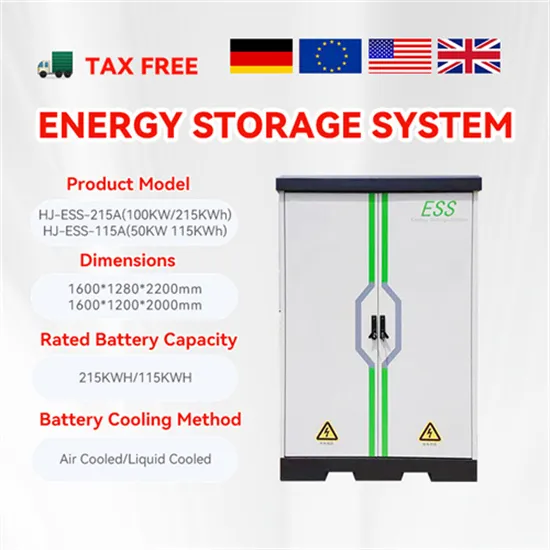

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.