SHINGLED CELL, CELL UNIT, AND SHINGLED PHOTOVOLTAIC ASSEMBLY

A shingled photovoltaic assembly, comprising a plurality of cell strings, each cell string being formed by connecting multiple cell units in series, with the cell units overlapping sequentially

Manufacturing method for shingled assembly and shingled assembly

In the background of promoting use of the solar energy which is a type of green energy, the shingled solar module reduces remarkably power loss based on the electrical principle of weak

Design of a solar cell electrode for a shingled photovoltaic

Apr 30, 2020 · New technologies to fabricate high-output power photovoltaic (PV) modules include a cell dividing and bonding technique. This technique divides and interconnects cells

Conductive adhesive based shingled solar cells: Electrical

Sep 15, 2022 · Introduction Shingled assembly of solar cells, initially described in a patent by Dickson in 1956 [1], involves overlapping of the cells in a PV module at their interconnection.

Understanding partial shading effects in shingled PV modules

May 15, 2020 · Top: Manufacturing stages of a shingled string from a square 6-inch solar cell template (left), after cutting/cleaving into individual shingles (center), and after assembly of a

SHINGLED CELL, CELL UNIT, AND SHINGLED PHOTOVOLTAIC ASSEMBLY

Mar 21, 2024 · Disclosed are a shingled cell, a cell unit, and a shingled photovoltaic assembly. The cell unit includes a cell. The front side of the cell includes a plurality of parallel front-side

Electrically Conductive Adhesives as Cell Interconnection

Dec 9, 2020 · Modules, in which pre-cut crystalline silicon solar cells – or shingles – are assembled into solar modules by placing the pre-cut cells in a shingle-like way on top of each

What are shingled solar modules?

Jul 6, 2020 · Not to be confused with "solar shingles" used in building-applied photovoltaics, shingled modules cut solar cells into strips and overlap them inside the framed module.

Shingled design lightweight photovoltaic modules using

Dec 1, 2024 · Consequently, we successfully fabricated lightweight PV modules with a shingled design, achieving a conversion power of 205.80 W in an area of 1.034 m 2, facilitating the

Shingling Technology For Cell Interconnection:

Sep 1, 2018 · Shingling technology is an extremely interesting development of cell interconnection in a photovoltaic module due to higher power densities at the same or lower cost, and

SHINGLED CELL, CELL STRIP, AND SHINGLED PHOTOVOLTAIC ASSEMBLY

Aug 2, 2023 · The shingled cell, the cell unit, and the shingled photovoltaic assembly are designed without busbars, greatly reducing electrode production cost. Description

Electrically Conductive Adhesives as Cell Interconnection

Dec 9, 2020 · Currently, there is market-available equipment capable of mass producing shingled modules [3] and with the work presented in this paper, it is demonstrated that by using the

PERC-based shingled solar cells and modules at

May 21, 2024 · Solar cell shingling, an approach first introduced in the 1950s, targets the reduction of CTM losses mainly by: 1) eliminating the cell spacing through the overlapping of

Solar cell chips, solar cell sheets, solar cell strings and shingled

The application provides a small solar cell sheet, a solar cell sheet, a solar cell string and a shingled assembly for preparing a shingled assembly, and relates to the field of photovoltaic

Challenges and advantages of cut solar cells for shingling

Jun 11, 2024 · 1 Introduction The growing demand of photovoltaic (PV) energy generation has driven the need for higher efficiency and increased power density in PV modules. To address

6 FAQs about [Photovoltaic cell shingled assembly]

What are shingled solar modules?

A solar panel manufacturing process that has gotten some traction recently is “shingling.” Not to be confused with “solar shingles” used in building-applied photovoltaics, shingled modules cut solar cells into strips and overlap them inside the framed module.

How much power does a shingled PV module produce?

Consequently, we successfully fabricated lightweight PV modules with a shingled design, achieving a conversion power of 205.80 W in an area of 1.034 m 2, facilitating the integration of more solar cells in a limited space. Additionally, standard reliability tests were performed on a PV module weighing only 6.2 kg/m 2. 1. Introduction

How do Solar shingles work?

Not to be confused with “solar shingles” used in building-applied photovoltaics, shingled modules cut solar cells into strips and overlap them inside the framed module. Intercell gaps are removed, and more silicon cells can be crammed into one module, increasing power output and module efficiency.

How shingled PV module is made?

The shingled PV module differs from the general module manufacturing method. The module is fabricated by arranging strings fabricated by dividing and bonding techniques in series and parallel as shown in Fig. 1. Thus, it must exhibit an electrode pattern suitable for the technology.

Can shingled solar cells be used in integrated modules?

a comparison of a parallel-stringing topology with a matrix topology of the cell interconnection. The reduced form factor of shingled solar cells makes them very appealing and effective for use in integrated module products, which is demonstrated by a successful automotive application, additionally profiting from the high p attained.

Are shingled solar cells available?

Commercial modules with shingled solar cells are currently available on the market [7,8], with a projection trend indicating an increasing market share in the upcoming years .

Learn More

- Photovoltaic cell silicon wafer assembly

- Ouagadougou photovoltaic cell assembly

- Photovoltaic solar cell energy storage cabinet price

- Processing photovoltaic power generation assembly panels

- Amsterdam photovoltaic panel assembly

- PV glass photovoltaic cell life

- The importance of photovoltaic cell components

- Baku Photovoltaic Cell Module Project

- Photovoltaic power station generator assembly

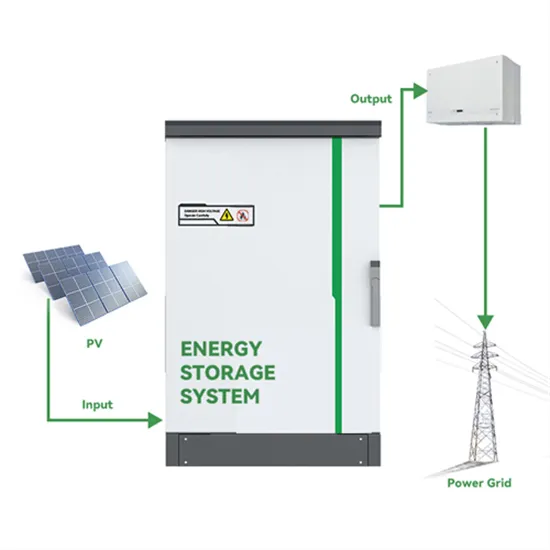

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.