Processes for the assembly and production of solar panels

Solar panels convert light into power, converting energy everywhere. However making solar panels requires complex material structures and production processes, read this article to

Photovoltaic applications: Status and manufacturing prospects

Mar 1, 2019 · At present, photovoltaic systems can be divided into five different categories: photovoltaic systems connected to a network, independent or isolated photovoltaic systems,

PRODUCTION PROCESS FOR PHOTOVOLTAIC CELL ASSEMBLY

Power electronics for PV modules, including power optimizers and inverters, are assembled on electronic circuit boards. This hardware converts direct current (DC) electricity, which is what a

Processing and assembling solar photovoltaic panels

What is solar panel manufacturing? Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to capture energy from the sun and convert it into usable

The research progress on recycling and resource utilization

Jun 15, 2024 · As a crucial component of renewable energy, photovoltaic (PV) power generation technology has rapidly emerged in the energy sector in recent years. In comparison to

The production process of solar photovoltaic modules

May 15, 2025 · The production process of solar photovoltaic modules can be divided into: solar cell inspection, front welding – inspection, back series connection – inspection, laying (glass

SOLAR PV POWER GENERATION: KEY INSIGHTS AND

Mar 23, 2023 · Solar PV consists several components including solar panels, inverter, photovoltaic mounting systems and other critical accessories that make up the system. Solar

How Are Solar Panels Manufactured Step-by-Step? A Clear

Discover the step-by-step journey of solar panel manufacturing, from high-purity silicon wafers to final assembly and quality testing. Explore key components like PV cells, tempered glass, and

Photovoltaic panel production cutting process

Solar manufacturing refers to the fabrication and assembly of materials across the solar value chain, the most obvious being solar photovoltaic (PV) panels, which include many

Potential assessment of photovoltaic power generation in

Feb 1, 2022 · The spatial distribution characteristics of PV power generation potential mainly showed a downward trend from northwest to southeast. Meanwhile, there were clear spatial

Photovoltaic cell assembly production process

Although the photovoltaic power generation process does not produce carbon emissions, the production process of the assembly is a high energy consumption industry, so the carbon

A review of automated solar photovoltaic defect detection

Dec 1, 2023 · The development of Photovoltaic (PV) technology has paved the path to the exponential growth of solar cell deployment worldwide. Nevertheless, the energy efficiency of

Environmental impacts of solar photovoltaic systems: A critical review

Mar 10, 2021 · Photovoltaic (PV) systems are regarded as clean and sustainable sources of energy. Although the operation of PV systems exhibits minimal pollution during their lifetime,

Photovoltaic power generation circuit board processing

Photovoltaic power generation circuit board processing Are solar PV Monitoring systems based on data processing modules? Firstly, the review of solar PV monitoring systems based on data

Solar power generation panel processing plant

A photovoltaic power plant is a large-scale PV system that is connected to the grid and designed to produce bulk electrical power from solar radiation. A photovoltaic power plant consists of

Photovoltaic factory solar panel handling process

Solar Photovoltaic Panel Production Line is a high-tech manufacturing process that converts sunlight into electricity using photovoltaic cells, involving cutting, assembling, and packaging

Solar PV Manufacturing Basics Explained

2 days ago · Solar photovoltaic (PV) manufacturing is the foundation of today''s clean energy revolution. From PV module manufacturing to racking systems and power electronics, each

Manufacturing Process of Solar Panels in 10 Stages

Jun 20, 2025 · The manufacturing of solar panels involves precision, clean-room environment, and advanced technology. From sand to silicon to solar electricity – it''s a learning journey of

6 FAQs about [Processing photovoltaic power generation assembly panels]

How are solar panels assembled?

Module Assembly Cells are assembled into solar panels (modules): Tabbing connects cells using conductive ribbons. Cells are laminated between EVA sheets, a tempered glass cover, and a backsheet. Everything is sealed under heat and pressure.

What materials are used in solar panel manufacturing?

Silicon, glass, aluminum, silver, and EVA plastic sheets are the main materials used in solar panel manufacturing. What is the first step in manufacturing a solar panel?

How a photovoltaic module is assembled?

The assembly of photovoltaic modules consists of a series of consecutive operations that can be performed by automatic machines dedicated to optimizing the single production phases that transform the various raw material in a finished product.

How a photovoltaic cell can be integrated into a production line?

Some of this equipment can be integrated into the production line according to the wished level of automation. The photovoltaic cells are placed in a piece of equipment, called solar stringer, that interconnects the cells in a series by soldering a coated copper wire, called ribbon, on the bus bar of the cell.

How to create a solar PV production process card?

Turn the solar cell front up and view it from different angles. Put the cells that have the same color and size in different groups. Each group should contain at least 36pcs, 60pcs and 72 pcs of solar cells. Put all the groups in the material tray. Fill the solar pv production process card and stick a barcode on this card.

What makes solar panels sustainable?

The manufacturing of solar panels involves precision, clean-room environment, and advanced technology. From sand to silicon to solar electricity – it’s a learning journey of science and innovation. As demand for renewable energy grows, so does the need for efficient and sustainable solar panel production.

Learn More

- Belarus photovoltaic panels rooftop power generation

- Is solar panels photovoltaic power generation

- The efficiency of photovoltaic panels in power generation in the north

- Power generation of photovoltaic panels laid flat and diagonally

- Photovoltaic power generation from solar panels in Lima

- Ghana solar panels photovoltaic power generation

- How many panels are there in a photovoltaic power generation group

- Will the material of photovoltaic panels affect power generation efficiency

- Camping photovoltaic panels for power generation

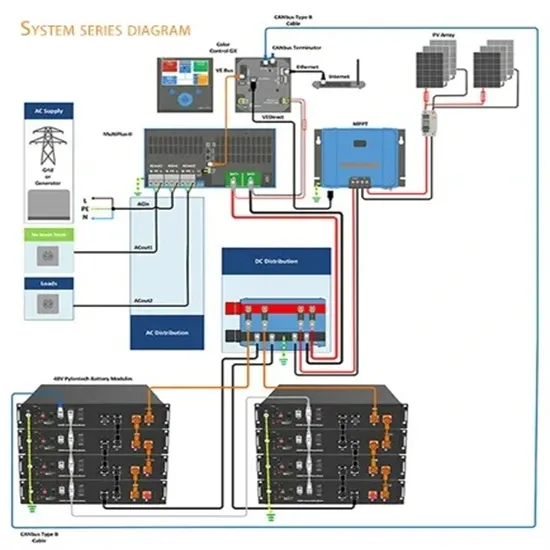

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.