Progress of PV cell technology: Feasibility of building materials

Jul 1, 2023 · Abstract Recently, the demand for PV technology by various sectors, including the public domain, industry, and space technology, has significantly increased. The feasibilities of

Efficiency, Materials, and Cost-Effectiveness of Photovoltaic Solar Panels

Jun 24, 2025 · 12.2.1 Principle Figure 12.1 illustrates the solar cell''s working principle of photovoltaic effect, discovered by Henri Becquerel in 1839 (Becquerel 1839). It involves

Temperature effect of photovoltaic cells: a review | Advanced

Among them, the temperature effect of SCs is related to their power generation efficiency, which is an important factor that needs to be considered in the development of SCs. The

Factors influencing the efficiency of photovoltaic system

Mar 1, 2019 · However, the power harnessed from solar PV is low due to its less conversion efficiency. Therefore, it is necessary to perform some critical analysis on the factors improving

The state of the art in photovoltaic materials and device

Mar 20, 2025 · Approaching the efficiency limits of PV technology requires material innovations and device designs that minimize these losses. Solar-cell research and development presents

Efficiency, Materials, and Cost-Effectiveness of Photovoltaic Solar Panels

Jun 24, 2025 · Power conversion efficiency (PCE) is a key feature of solar PV, influenced by factors such as the material used in the PV cell, insolation, temperature, and shading. Ongoing

Future of photovoltaic technologies: A comprehensive review

Oct 1, 2021 · After this brief introductory section, the rest of the article is organized as follows. The theoretical background is briefly discussed in Section 2. Section 3 delineates the recent

Overview: Photovoltaic Solar Cells, Science, Materials,

Dec 1, 2023 · The essential solar generation of energy unit is a photovoltaic (PV) cell whereas sunlight is converted to electrical energy. A p-n junction device is a solar cell whereas p-type

Enhancement of power generation efficiency through the

May 5, 2025 · When this phenomenon occurs on photovoltaic solar panels, fog condensation affects the transparency of the surface, which reduces the efficiency of photovoltaic power

Photovoltaic materials: Present efficiencies and

Apr 15, 2016 · High-efficiency (>20%) materials can find applications in large-area PV power generation for the utility grid, as well as in small and medium-sized

Power generation evaluation of solar photovoltaic systems

Dec 1, 2024 · Photovoltaic power generation is affected by a variety of factors, such as PV panel material, inclination angle, and solar radiation intensity. Electricity generation efficiency is not

Photovoltaic Cell Efficiency

PV cell efficiency is defined as the ability of a solar photovoltaic cell to convert radiative energy into electrical energy, typically measured as the ratio of electrical power output to the total

The environmental factors affecting solar photovoltaic output

Feb 1, 2025 · The global expansion of solar photovoltaics (PV) is central to the global energy transition. As governments aim to triple renewable energy capacity by 2030, solar PV is poised

Solar Panel Efficiency: Factors That Affect the Efficiency of

Jul 29, 2024 · Solar panels, made from materials like silicon, are innovative devices designed to efficiently convert light into electricity, offering a sustainable energy solution for a greener

Innovations in improving photovoltaic efficiency: A review of

Mar 1, 2025 · A detailed exploration of recent advancements in PV materials, technological innovations, and operational optimizations is provided, based on an analysis of over 7,200

Comprehensive study on photovoltaic cell''s generation and

Feb 19, 2025 · The utilization of fossil fuels for power generation results in the production of a greater quantity of pollutants and greenhouse gases, which exerts detrimental impacts on the

An integrated review of factors influencing the perfomance

Dec 1, 2017 · There is a built-in electric field in PV panels as they contain junctions between different materials. These junctions follow a certain behavior once the panel absorbs photons

Photovoltaic Efficiency: The Temperature Effect

Feb 11, 2020 · Fundamentals Article This article examines how the efficiency of a solar photovoltaic (PV) panel is affected by the ambient temperature. You''ll learn how to predict the

Increasing Efficiency of Solar Panels via Photovoltaic Materials

Feb 12, 2021 · This paper will not only provide us with the comparison between Thin Film Solar Cells (Cadmium telluride), Perovskite Solar cells and Dye-Sensitized Solar cells, but also will

Enhancing concentrated photovoltaic power generation efficiency

Sep 15, 2024 · Given the pressing climate issues, including greenhouse gas emissions and air pollution, there is an increasing emphasis on the development and utilization of renewable

Factors influencing the efficiency of photovoltaic system

Mar 1, 2019 · In this paper, an attempt is made in performing a detailed comprehensive review on the factors affecting the efficiency of solar cell. A detailed review is carried out on basic

Unleashing the Power: A Comprehensive Guide

May 27, 2024 · Factors Affecting Photovoltaic Efficiency Several factors can affect the efficiency of photovoltaic systems, including both intrinsic properties of the

Evaluating solar photovoltaic power efficiency based on

Apr 1, 2023 · Renewable energy achieved a 28.8% share of the global electricity supply in 2020, the highest level on record, with solar photovoltaic (PV) and wind each accounting for about

6 FAQs about [Will the material of photovoltaic panels affect power generation efficiency ]

How efficient are solar panels?

The efficiency of solar panels largely depends on the materials used in their construction, with silicon standing out as the predominant semiconductor material in both crystalline and thin-film solar cells. Silicon's vital role in solar technology cannot be overstressed.

How to increase the efficiency of a photovoltaic system?

The efficiency can be increased by implementing highly efficient material for manufacturing solar cells, finding appropriate MPPT techniques to identify maximum power point and to avoid load mismatch problems and on DC-DC converters. This paper gives an overview on the factors influencing the efficiency of the photovoltaic system.

What are the factors affecting the efficiency of solar cells?

The dability, a vailability, cost, temperature stability, degradation rate, and other parameters. The sensible engineering of effective to third generation solar cells. The impact of material alterations is delineated in PV, where the efficiency of solar cell tech nology has improved from 4% to 47.1%.

Why do large-area photovoltaic systems need high-efficiency solar cells?

Because the cost of photovoltaic systems is only partly determined by the cost of the solar cells, efficiency is a key driver to reduce the cost of solar energy, and therefore large-area photovoltaic systems require high-efficiency (>20%), low-cost solar cells.

Why is efficiency important in photovoltaic systems?

The rate of development and deployment of large-scale photovoltaic systems over recent years has been unprecedented. Because the cost of photovoltaic systems is only partly determined by the cost of the solar cells, efficiency is a key driver to reduce the cost of solar energy.

What factors affect solar PV system efficiency?

Another factor which has the direct impact on PV system efficiency is MPPT technique. The maximum power can be trapped using proper MPPT technique. It is also employed along with DC-DC converter. A summary is made on comparing the conventional and soft computing MPPT methods for solar PV system.

Learn More

- The efficiency of photovoltaic panels in power generation in the north

- Does the heating of photovoltaic panels affect power generation

- 100 Average power generation of photovoltaic panels

- Add photovoltaic panels to photovoltaic power generation

- Photovoltaic power generation 60 square meters of photovoltaic panels

- Ghana solar panels photovoltaic power generation

- How many panels are there in a photovoltaic power generation group

- Power generation of 1 square meter of photovoltaic panels in Dublin

- The difference between photovoltaic panels and power generation panels

Industrial & Commercial Energy Storage Market Growth

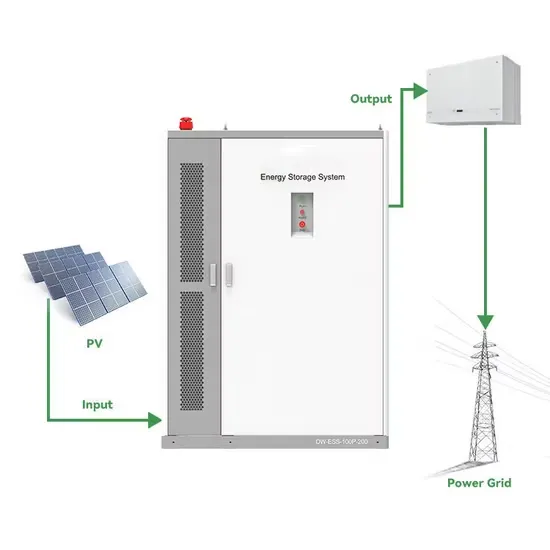

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

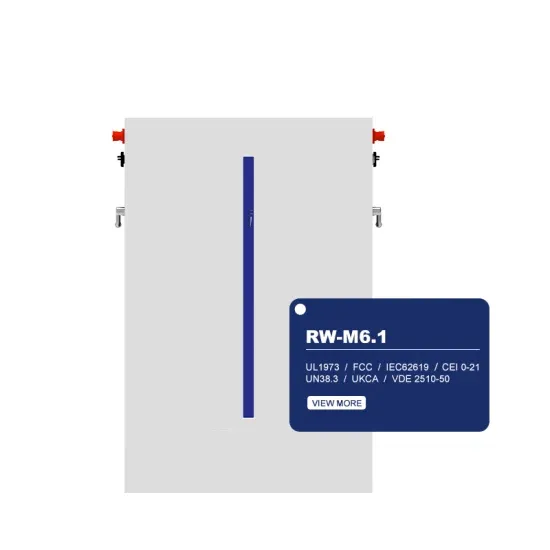

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.