Solar photovoltaics deployment impact on urban

Oct 1, 2024 · The generation of power in PV panels results in significant heat production as solar energy is converted into electricity throughout the system. This heat modifies the thermal

Does A Solar Panel Increase Heat

Oct 26, 2024 · The Photovoltaic Heat Island (PVHI) effect occurs when areas with solar panels become warmer than their surroundings. This happens because solar panels absorb sunlight

Recent technical approaches for improving energy efficiency

Mar 1, 2023 · PV-thermal (PV-T) systems generate electricity and thermal energy simultaneously because PV cells are converting solar radiation into power and are playing the role of a

Effect of tilt angle on the performance and electrical parameters

Jul 1, 2022 · Influence of tilt and orientation angle of the PV panels on high-energy production in Romanian climate conditions during cold season, IEEE Environment and Electrical

Does the heating of solar panels affect power generation

As the photovoltaic (PV) industry continues to evolve, advancements in Does the heating of solar panels affect power generation have become critical to optimizing the utilization of renewable

On the local warming potential of urban rooftop photovoltaic

Sep 20, 2023 · Results showed that increasing PVSPs can raise peak summer ambient temperatures by up to 1.4 °C and surface temperatures by up to 2.3°C at city-scale.

Weathering the Change: How Weather Affects Solar

Apr 16, 2024 · Temperature: Contrary to popular belief, solar panels operate more efficiently in cooler temperatures. High temperatures can reduce the efficiency of photovoltaic cells,

Heat Generation in Solar Panels: An In-Depth

Aug 6, 2025 · In summary, the photoelectric effect contributes to heat generation in solar panels, while temperature critically affects their efficiency. Recognizing

Shading effect and energy-saving potential of rooftop photovoltaic

Nov 15, 2023 · The model presented in this paper provides theoretical guidance for analyzing the comprehensive energy-saving effects of photovoltaic rooftop systems and reveals the potential

Photovoltaic solar energy: generating electricity

Dec 18, 2009 · Photovoltaic energy is a form of renewable energy obtained from solar radiation and converted into electricity through the use of photovoltaic

Does the sun affect the power generation of

Jan 2, 2024 · How does sunlight affect a solar panel''s performance? In addition to sunlight, the intensity of the sun''s heat will affect your solar panel''s performance. Although sunlight is

Photovoltaic Efficiency: The Temperature Effect

Feb 11, 2020 · Cooling the PV panels allows them to function at a higher efficiency and produce more power. Panels can be cooled actively or passively. An active system requires some

Enhancing the power generation performance of photovoltaic

Mar 1, 2024 · The rise in the surface temperature of a photovoltaic (PV) module due to solar heat significantly reduces the power generation performance of the PV system. Photovoltaic

Solar Panels Use Light, Not Heat – Here''s Why

Apr 25, 2025 · Solar panels use light to generate electricity, not heat. Learn how temperature, sunlight, and panel efficiency impact solar performance and savings.

6 FAQs about [Does the heating of photovoltaic panels affect power generation ]

How does heat affect a solar panel's power production?

In fact, voltage reduction is so predictable that it can be used to measure temperature accurately. As a result, heat can severely reduce the solar panel's power production. In the built environment, there are a number of ways to deal with this phenomenon.

Does temperature affect solar panel efficiency?

It may seem counterintuitive, but solar panel efficiency is negatively affected by temperature increases. Photovoltaic modules are tested at a temperature of 25° C - about 77° F, and depending on their installed location, heat can reduce output efficiency by 10-25%.

Does solar radiation affect PV power generation?

The effects of solar radiation, surface temperature, and relative humidity on the power generated by the PV and PVT systems were observed. The accuracy of the PV power generation prediction formula, substituting the measured variables for the diverse environmental influences during summer, was 97.41 %, whereas the accuracy for PVT was 96 %.

Do solar panels generate heat?

Heat generation in solar panels is a significant, but often misunderstood aspect of solar energy technology. This article seeks to clarify its intricacies by providing a detailed analysis of how heat affects both the performance and efficiency of solar panels.

Can photovoltaic-thermal systems predict power generation?

Photovoltaic-Thermal (PVT) systems are being developed to overcome these limitations. The study discusses predicting power generation in PV and PVT systems. It identifies essential variables, such as solar radiation, relative humidity, and module surface temperature, that influence power generation. Regression equations were derived for PV and PVT.

Why is heat generation important in solar panels?

The mechanisms of heat generation in solar panels play a pivotal role in understanding their overall performance and efficiency. Heat is an inherent byproduct of the energy conversion process, and its management is crucial for optimal functioning.

Learn More

- Will the material of photovoltaic panels affect power generation efficiency

- Photovoltaic power generation from solar panels in Zagreb

- Belarus photovoltaic panels rooftop power generation

- Mozambique polycrystalline photovoltaic panels power generation

- Will photovoltaic panels affect the number of hours of electricity generation

- Add photovoltaic panels to photovoltaic power generation

- Power generation panels photovoltaic panels

- Solar panels photovoltaic power generation in Equatorial Guinea

- Photovoltaic power generation 60 square meters of photovoltaic panels

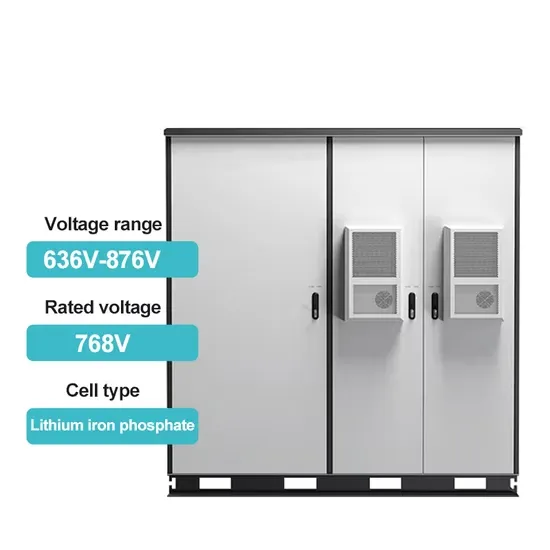

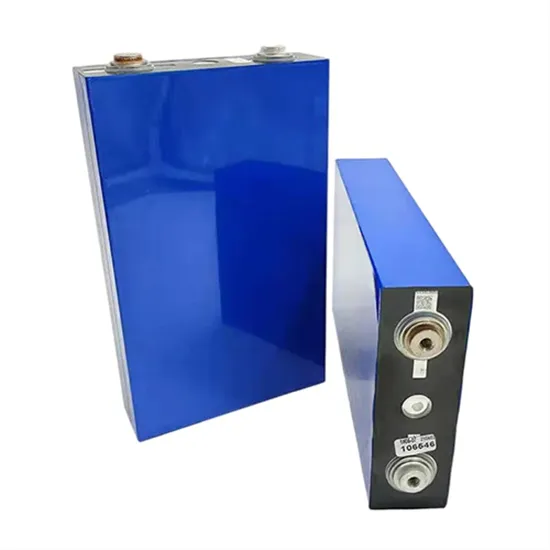

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.