NGA Presents Updated Resource on Glass Properties

Mar 28, 2025 · NGA volunteers update Glass Technical Papers (GTPs) through the systematic review ballot process on a 5-year cycle. Among structural materials, glass has many

Types of photovoltaic solar panels and their

Nov 6, 2017 · Types of photovoltaic solar panels: characteristics and advantages for your installation Photovoltaic solar panels are devices specifically designed

Detailed Solar Panel Raw Material List for Quality

Apr 29, 2023 · Explore the essential solar panel raw materials for solar panel production. Learn how quality components ensure durable, efficient, and high

Polymer multilayer film with excellent UV-resistance & high

Aug 15, 2021 · The choice of polymer material as photovoltaic (PV) module front cover is important to realize high optical transparency and high UV-resistance. We have successfully

Photovoltaic Module: Definition, Importance, Uses and Types

Jul 5, 2024 · A photovoltaic (PV) module is a unit comprised of PV cells that gather sunlight and turn it into energy. Each module contains multiple PV cells shielded by different materials

Materials selection investigation for thin film photovoltaic module

Jul 15, 2019 · By performing a broad-based material selection methodology to investigate materials and processes suitable for encapsulation of thin film PV modules, there exists

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Solar Glass & Mirrors Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the

Main material components of photovoltaic panel glass

The composition study indicates that the main components of PV modules include silicon, glass, aluminum, copper, plastic, and other elements, with silicon being the The main components

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · 1. What is solar photovoltaic glass?Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by

Material study of photovoltaic modules with silicone

Sep 15, 2021 · An important component of photovoltaic modules is the encapsulant, which is the material that surrounds solar cells and protects them from shock and environmental attack.

Investigation of combustion hazards of glass photovoltaic

May 15, 2025 · At present, the application scale of glass panel photovoltaic modules worldwide is rapidly increasing, and they are widely used in centralized and distributed photovoltaic power

Structure and Materials of PV Modules

Nov 29, 2017 · Structure and Materials of PV Modules A crystalline silicon module must withstand various influences in order to remain functional for 25 years or even longer.

Experimental investigation on the combustion performance

Jun 15, 2025 · Under similar glass material conditions, double-glazed modules exhibited superior combustion performance compared to their single-glass counterparts. Therefore, locations

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

Encapsulant Materials and Their Adoption in Photovoltaic Modules

Jun 12, 2023 · In the last two decades, the continuous, ever-growing demand for energy has driven significant development in the production of photovoltaic (PV) modules. A critical issue

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

Solar Glass: What Is It & What Is Its Role In Solar

Jul 22, 2021 · Main materials of solar glass The main raw materials of solar glass include quartz sand, soda ash, limestone, dolomite, sodium nitrate, mirabilite,

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

Main raw materials and components of solar cell modules

Sep 26, 2020 · Generally, there are tempered glass, plexiglass, aluminum alloy, TPT composite film, and so on. The tempered glass backsheet is mainly used to make double-sided light

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating solar cells, and has related

6 FAQs about [Glass the main material of photovoltaic modules]

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

What type of glass is used in solar panels?

The type of solar glass directly influences the amount of solar radiation that is being transmitted. To ensure high solar energy transmittance, glass with low iron oxide is typically used in solar panel manufacturing. Solar panels are made of tempered glass, which is sometimes called toughened glass.

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

What are solar cells made of?

It is composed of low iron glass, solar cells, film, back glass, and special metal wires. The solar cells are sealed between a low iron glass and a back glass through film, making it the most innovative high-tech glass product for construction. Using low iron glass to cover solar cells can ensure high solar transmittance.

What is solar glass?

Solar Glass is one of the crucial barriers of traditional solar panels protecting solar cells against harmful externalities, such as water, vapor and dirt.

What raw materials are used in Photovoltaic Glass production?

The raw materials used in the production of photovoltaic glass raw materials include soda ash, quartz sand, feldspar, dolomite, limestone, mirabilite, etc. Quartz sand and soda ash are not only the main components in material input, but also the two types of raw materials that have a significant impact on material costs.

Learn More

- Doha monocrystalline silicon single glass photovoltaic modules

- Main production areas of photovoltaic glass

- The main function of photovoltaic glass

- Ultra-white solar glass photovoltaic modules

- Ultra-thin lightweight glass photovoltaic modules

- Antimony is used in photovoltaic glass

- How much pressure does photovoltaic glass have

- What is required for photovoltaic glass processing

- Asian single glass photovoltaic curtain wall manufacturer

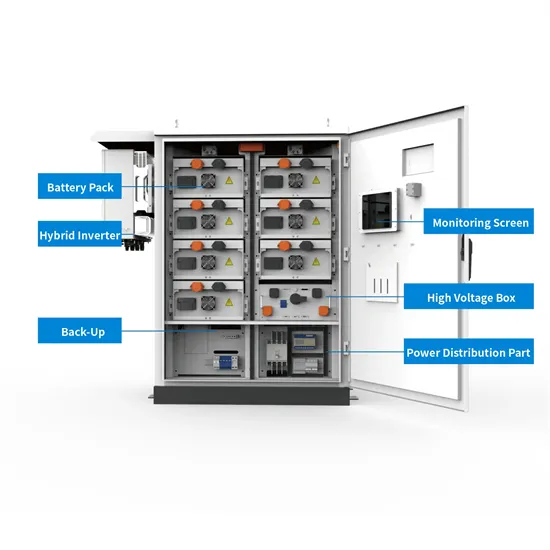

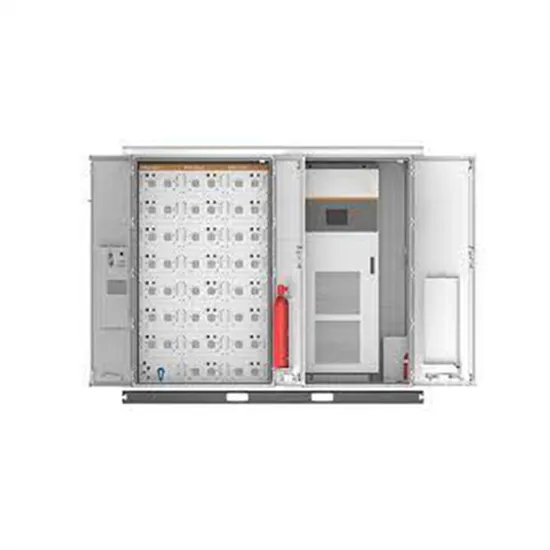

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.