Transparent Tedlar® Frontsheet for Lightweight PV Module

Jun 16, 2023 · The main challenge in acheiving lightweight PV modules is replacing the glass frontsheet while maintaining transparency, mechanical stability and weatherability over the

Narrow Bandgap CIGS Solar Cells on Flexible, Light Weight Glass

Jun 14, 2024 · CIGS absorbers with a near-infrared bandgap make excellent candidates for a bottom cell in multi-junction solar cell designs. These devices, available in flexib.

Advancements In Ultra-Thin Solar Glass: Benefits And

Jul 26, 2024 · Advancements in ultra-thin solar glass are revolutionizing the field of photovoltaic (PV) systems. This new technology involves producing solar glass with a thickness of as little

Optimization of large-area photovoltaic module frames for lightweight

Jun 15, 2025 · In this study, we used the non-dominated sorting genetic algorithm-II (NSGA-II), a meta-heuristic optimization technique, and structural analysis simulation to design a

Ultrathin Glass for the Photovoltaic Applications

Mar 9, 2021 · In this work we demonstrate that chemically strengthened ultrathin glass is a perfect material for the photovoltaic applications, i.e. as a substrate for deposition of thin layers and for

High-efficiency cadmium-free Cu(In,Ga)Se2 flexible thin-film

Apr 20, 2025 · This study successfully demonstrated high-efficiency Cu (In,Ga)Se₂ (CIGSe) thin-film solar cells on flexible ultra-thin glass (UTG) substrates, balancing mechanical flexibility

Ultra-thin Rolled Photovoltaic Glass – New Way

Jun 16, 2024 · Improving the transmittance of ultra-thin photovoltaic glass can effectively enhance the efficiency of solar photovoltaic modules. The industry

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · NREL Photovoltaic Module Reliability Workshop February 16, 2011 Photovoltaic Glass Technologies Corning has a long history of life-changing innovations Glass envelope for

In situ vapor-deposited parylene substrates for ultra-thin, lightweight

Apr 1, 2016 · We use in situ vapor-phase growth of smooth, transparent, and flexible parylene-C films to produce ultra-thin, lightweight molecular organic solar cells as thin as 2.3 μm including

Printed Organic Photovoltaic Modules on Transferable Ultra‐thin

Dec 9, 2022 · To date, demonstrations of such ultra-thin photovoltaics have been limited to small-scale devices, often prepared on glass carrier substrates with only a few layers solution

Ultra-thin PV Glass-Quantum Materials Technology (Suzhou)

Despite their thinness, ultra-thin PV glass panels can achieve high energy conversion efficiencies comparable to traditional PV modules. Advances in materials and manufacturing processes

Perovskite Photovoltaics on Roll-To-Roll Coated Ultra-thin Glass

May 20, 2020 · Such high efficiencies of PV cells on ultra-thin glass opens up the potential for these devices to be integrated in portable devices, wireless sensor nodes, and low-power

INSTRUCTIONS FOR PREPARATION OF PAPERS

Sep 23, 2022 · The lightweight solar module is achieved by replacing the standard glass frontsheet by a thin transparent polymeric layer and by engineering the backsheet to replace

Inventions, innovations, and new technologies: Flexible and lightweight

Sep 1, 2023 · For flexible PV, ultra-thin flexible glass substrates might have issues with this semiconductor because of dissimilar thermal expansion coefficients compared to soda-lime glass.

Effect of bending test on the performance of CdTe solar cells

Jul 1, 2020 · Ultra-thin glass (UTG) however is far better suited and can yield a lightweight and flexible, in 1-dimension, PV module. The suitability of UTG substrates to roll-to-roll processes

Ultra-thin PV Glass-Quantum Materials Technology (Suzhou)

Ultra-thin PV glass is significantly lighter than conventional glass, making it easier to handle, transport, and install. This characteristic is particularly advantageous for applications where

Narrow Bandgap CIGS Solar Cells on Flexible, Light Weight Glass

Jun 14, 2024 · CIGS absorbers with a near-infrared bandgap make excellent candidates for a bottom cell in multi-junction solar cell designs. These devices, available in flexible and

Heliup switches on 100 MW lightweight solar panel factory

May 29, 2025 · Heliup has commissioned a 100 MW factory in France to produce lightweight solar panels for flat commercial and industrial (C&I) rooftops with limited load-bearing capacity,

Towards fiber-reinforced front-sheets for lightweight PV modules

Oct 15, 2024 · Novel approaches in the field of photovoltaics, such as building or vehicle integration require investigations of lightweight PV module concepts [1]. This research

Building-integrated photovoltaic applied Bi-facial photovoltaic module

Jun 1, 2024 · Most photovoltaic modules typically exhibit a structure configuration of either glass-to-back sheet or glass-to-glass. These configurations are widely used in standard construction

6 FAQs about [Ultra-thin lightweight glass photovoltaic modules]

Are ultra-thin organic photovoltaics scalable?

To date, demonstrations of such ultra-thin photovoltaics have been limited to small-scale devices, often prepared on glass carrier substrates with only a few layers solution-processed. We demonstrate large-area, ultra-thin organic photovoltaic (PV) modules produced with scalable solution-based printing processes for all layers.

Can a bulk heterojunction material be used for large-area photovoltaic modules?

Prior to developing a process to build fully-printed large-area photovoltaic modules, an organic bulk heterojunction material system was selected and evaluated for its suitability for such an application, on small-scale glass substrates with sputtered transparent electrodes.

What are thin-film photovoltaics?

Thin-film photovoltaics with functional components on the order of a few microns, present an avenue toward realizing additive power onto any surface of interest without excessive addition in weight and topography.

Can cadmium-free solar cells be used on ultra-thin glass?

The new cell concept was introduced in the study “ High-efficiency cadmium-free Cu (In,Ga)Se 2 flexible thin-film solar cells on ultra-thin glass as an emerging substrate,” published in the Journal of Alloys and Compounds.

How much does a silicon PV module weigh?

For comparison, we note that silicon PV modules on glass substrates have a specific power of 20 W/kg and weigh 10.7 kg m −2 (for example, see SunPower's Maxeon Gen 5, 400 W Residential A-Series Panels), 18-times less power per kg, and 100-times more weight per m 2, than our fabric-PV modules.

Can ultra-thin modules be integrated into fabric-PV systems?

Integration of the ultra-thin modules onto composite fabrics lends mechanical resilience to allow these fabric-PV systems to maintain their performance even after 500 roll-up cycles. This approach to decouple the manufacturing and integration of photovoltaics enables new opportunities in ubiquitous energy generation.

Learn More

- Ultra-thin and lightweight photovoltaic panel prices

- Tirana double glass photovoltaic modules

- Buenos Aires New Energy Ultra-thin Photovoltaic Glass

- Serbia Lightweight Photovoltaic Glass Direct Sales

- Characteristics of St John s Lightweight Photovoltaic Glass

- Doha monocrystalline silicon single glass photovoltaic modules

- What does photovoltaic glass curtain wall mean

- Rooftop photovoltaic glass sun room

- Which glass photovoltaic power generation company is the best in Sao Tome and Principe

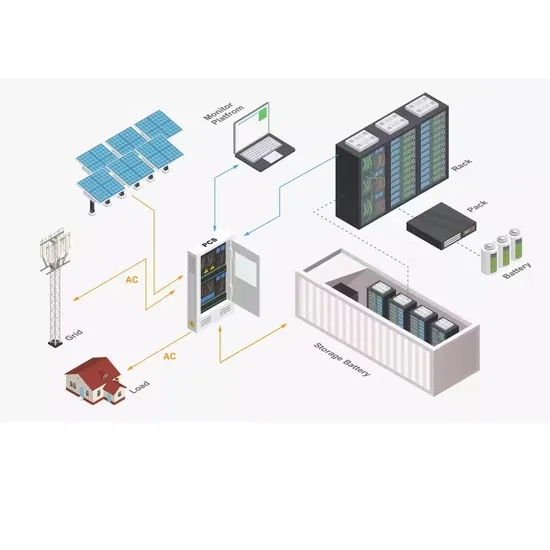

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

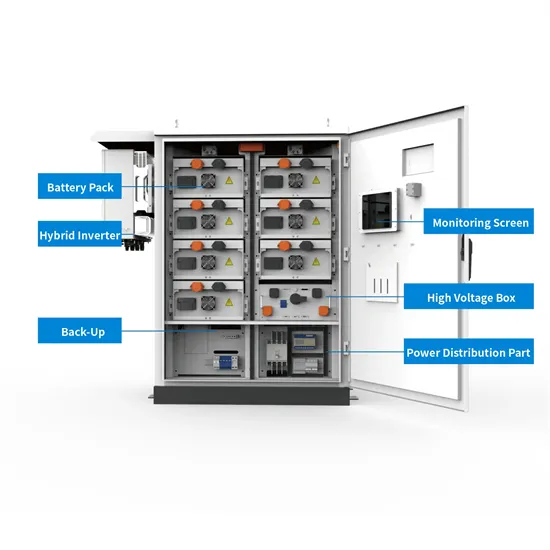

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.