Building-integrated photovoltaic applied Bi-facial photovoltaic

Jun 1, 2024 · Most photovoltaic modules typically exhibit a structure configuration of either glass-to-back sheet or glass-to-glass. These configurations are widely used in standard construction

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating solar cells, and has related

Experimental investigation of photoelectrical performance

The existing large-scale of industrial buildings with lightweight insulated roofing structures presents a challenge for traditional glass crystalline silicon photovoltaicExperimental

Characteristics Of Photovoltaic Glasses | British Glass

For photovoltaic uses, glass has to create different properties for different technologies and tasks. In this article, the author presents a strategy to reduce the cost per square meter by 70%, with

Shingled design lightweight photovoltaic modules using

Dec 1, 2024 · The expanding scale of the photovoltaic (PV) market has intensified the focus on PV module designs for diverse applications. Research actively pursues lightweight PV modules,

Optimization of Shingled-Type Lightweight Glass-Free Solar

Abstract Read online High-power and lightweight photovoltaic (PV) modules are suitable for building-integrated photovoltaic (BIPV) systems. Due to the characteristics of the installation

Optimization of Shingled-Type Lightweight Glass-Free

Further, we employed an ethylene tetrafluoroethylene sheet instead of a front cover glass and added an Al honeycomb sandwich structure to enhance the mechanical stability of lightweight

Thermo-mechanical stability of lightweight glass-free photovoltaic

Dec 1, 2018 · This work focuses on the development of a lightweight, glass-free photovoltaic (PV) module (6 kg/m2) composed of a composite sandwich back-structure and a polymeric front

A Study of the Electrical Output and Reliability

Dec 31, 2020 · PV modules and systems [8–10]. A lightweight PV module has the advantage of being easier to install on weak ground or in aged buildings. For this reason, a PV module

Solar Photovoltaic Glass: Classification and Applications

Jun 26, 2024 · Demand for solar photovoltaic glass has surged due to growing interest in green energy. This article explores types like ultra-thin, surface-coated, and low-iron glass used in

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency. Advances in glass compositions,

Damp‐Heat–Induced Degradation of Lightweight Silicon

Jan 12, 2025 · Lightweight photovoltaic applications are essential for diversifying the solar energy supply. This opens up vast new scenarios for solar modules and significantly boosts the

Thermo-mechanical stability of lightweight glass-free photovoltaic

Request PDF | On Dec 1, 2018, Ana C Martins and others published Thermo-mechanical stability of lightweight glass-free photovoltaic modules based on a composite substrate | Find, read and

Polymer multilayer film with excellent UV-resistance & high

Aug 15, 2021 · The choice of polymer material as photovoltaic (PV) module front cover is important to realize high optical transparency and high UV-resistance. We have successfully

Flexible photovoltaic modules based on amorphous hydrogenated silicon

May 6, 2015 · Solar cells on lightweight and flexible polymer substrates have a number of unquestionable advantages in both terrestrial and space applications over photovoltaic

Experimental investigation of photoelectrical performance

May 19, 2024 · The existing large-scale of industrial buildings with lightweight insulated roofing structures presents a challenge for traditional glass crystalline silicon photovoltaic (PV)

A Study of the Electrical Output and Reliability

Dec 31, 2020 · In this paper, ultra-barrier film (UBF), ETFE (ethylene tetra fluoro-ethylene) film and ECTFE (ethylene chlorotrifluoroethylene), which is likely to be applied as a front-surface

Experimental investigation of photoelectrical performance

Jul 1, 2024 · Abstract The existing large-scale of industrial buildings with lightweight insulated roofing structures presents a challenge for traditional glass crystalline silicon photovoltaic (PV)

Multi-objective evolutionary optimization of photovoltaic glass

Nov 1, 2023 · Optimized results of low-E semi-transparent amorphous-silicon photovoltaic glass applied on the façade show that the spatial daylight autonomy is increased to 82% with

Lightweight photovoltaic modules technologies:

Two types of lightweight modules are tested: composite/polymer often based on ETFE and/or berglass reinforced plastics and fi glass/polymer modules with a maximum power varying

Types of photovoltaic solar panels and their

Nov 6, 2017 · Photovoltaic solar panels are devices specifically designed for the generation of clean energy from sunlight. In general, photovoltaic panels are

Experimental investigation of photoelectrical performance

Jul 1, 2024 · Experimental investigation of photoelectrical performance and thermal characteristics of ventilated building-integrated photovoltaic system utilizing lightweight and flexible crystalline

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Weathering of float glass can be categorized into two stages: "Stage I": Ion-exchange (leaching) of mobile alkali and alkaline-earth cations with H+/H3O+, formation of

Experimental investigation of photoelectrical performance

Jul 1, 2024 · The existing large-scale of industrial buildings with lightweight insulated roofing structures presents a challenge for traditional glass crystalline silicon photovoltaic (PV)

Optimization of Shingled-Type Lig... preview & related info

Abstract High-power and lightweight photovoltaic (PV) modules are suitable for building-integrated photovoltaic (BIPV) systems. Due to the characteristics of the installation sites, the BIPV solar

A framework of optimum cleaning schedule and its financial

Sep 7, 2022 · A. Azouzoute et al., Modeling and experimental investigation of dust effect on glass cover PV module with fixed and tracking system under semi-arid climate, Sol. Energy Mater.

6 FAQs about [Characteristics of St John s Lightweight Photovoltaic Glass]

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

What are the characteristics of thin film solar cells?

A notable characteristic of thin film solar cells is the absence of glass materials in their front cover. Even in c-Si solar cells, lightweight modules that utilize alternative materials instead of a front glass cover have been reported [, , , , ].

Why is Solar Photovoltaic Glass so popular?

With global attention on environmental protection and energy efficiency steadily rising, the demand for solar photovoltaic glass in both commercial and residential construction sectors has significantly increased. The desire to reduce energy costs and carbon footprint has driven the widespread adoption of solar photovoltaic glass.

How much iron is in solar glass?

Therefore, strict requirements are imposed on the iron content in the silicon raw materials used for producing solar glass, with Fe2O3 content typically ranging from 140 to 150 ppm. According to reports, Germany was the first country to use transparent flat glass as a substrate for developing solar cells.

Which glass is used in photovoltaic power generation?

The glass used in photovoltaic power generation is not ordinary glass, but TCO conductive glass. HHG is a professional glass manufacturer and glass solution provider include range of tempered glass, laminated glass, textured glass and etched glass.

Why is glass important for solar energy?

Despite the abundance of solar radiation , significant energy losses occur due to scattering, reflection, and thermal dissi-pation. Glass mitigates these losses by functioning as a protective layer, optical enhancer, and spectral converter within PV cells.

Learn More

- Serbia Lightweight Photovoltaic Glass Direct Sales

- Ultra-thin lightweight glass photovoltaic modules

- St John s new photovoltaic panels for sale

- How much is the photovoltaic glass factory in Greece

- Photovoltaic glass quality

- Photovoltaic glass secondary factory

- Photovoltaic panel glass greenhouse

- Eastern Europe invests in photovoltaic glass

- Sri Lanka photovoltaic glass

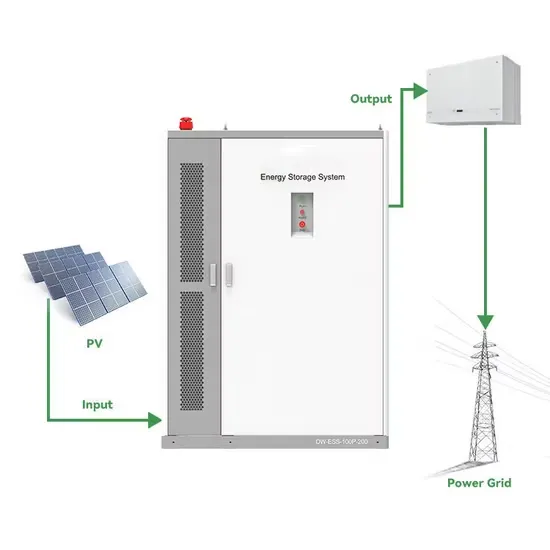

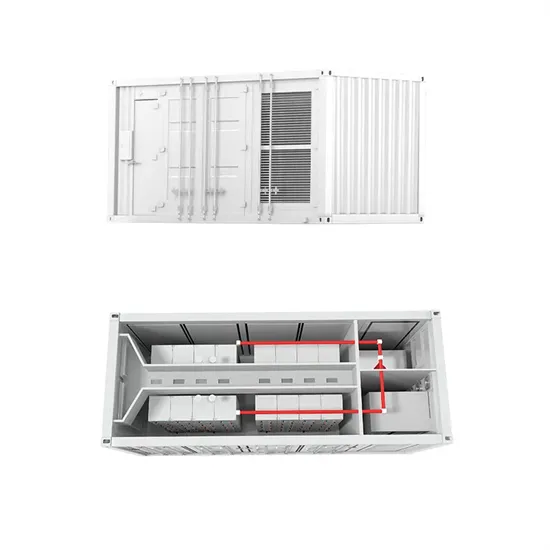

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.