Impact of silicon and other contaminants on the melting

Highlights • Reactions between PV glass and elements contained in PV panel were investigated. • Contamination by Cu, Al, and Si caused coloration to the melting glass. • Si contamination

Evolution and state-of-the-art development of antimony

Jan 15, 2025 · 2.1. Device architectures and fabrication strategies The fabrication process determines the quality of any film because excellent Photovoltaic performance directly

First attempt to build antimony photovoltaic

Mar 12, 2024 · An Italian research team claims a first for solar modules based on air stable lead-free and tin-free antimony-based light absorber, a perovskite

China Tightens Grip on Strategic Minerals with New Antimony

Aug 17, 2024 · Antimony is also a key input for the production of photovoltaic glass used in solar cells, as well as for lead-acid batteries.The new restrictions from China apply to six categories

NoSbEra Antimony Free Solar Glass

Borosil has developed NoSbEra: World''s first Antimony-free solar glass. The world is staring at a burning issue of the most hazardous substance "Antimony" present in solar glass. Skin and

Management of Antimony Containing Solar PV Glass

May 5, 2019 · Antimony is used in solar glass to improve light refraction and visible transmission property. It also increases the resistance of glass to the ultraviolet light for the long term.

(PDF) Exploring antimony material flow in the context of

Jun 23, 2025 · Estimated recyclable antimony (Sb) in end-of-life PV glass by region from 2000 to 2050. (Note: In each subplot, solid-colored lines represent regional antimony demand under

Efficiency and Sustainability: Recent innovations

Feb 3, 2021 · The quality of equipment used in concentrated solar power (CSP) and solar photovoltaic (PV) plants has a major role to play in increasing the

Solar panel recycling could be more sustainable | RIVM

May 15, 2024 · RIVM looked into ways being developed to reuse raw materials used in solar panels. The four ways described by RIVM in this report are more sustainable than how solar

Concept Note/ Blue Print on Management of Antimony

Mar 27, 2018 · 2. Antimony Containing Solar PV Panels rove stability of the solar performance of the glass upon exposure to ultraviolet radiation and/or sunlight. The combination of low iron

Concept Note/ Blue Print on Management of Antimony

Mar 27, 2018 · 2. Antimony Containing Solar PV Panels Antimony is used in solar panel glass to improve stability of the solar performance of the glass upon exposure to ultraviolet radiation

Antimony-Free Solar Glass | British Glass

Antimony is a highly toxic element, present at remote locations in our planet, and is used in some glasses to enhance its optical performances. Antimony is not present in common glasses,

Addressing uncertain antimony content in solar glass for

Nov 7, 2023 · However, the composi on of solar glass varies, par cularly in terms of an mony content, depending on the produc on method. An mony is used to enhance the performance of

Exploring antimony material flow in the context of energy

Aug 1, 2025 · In PV glass, antimony is chemically embedded within the glass matrix, making its separation energy-intensive and technically challenging. In EEE products, antimony is typically

Management of Antimony Containing Solar PV Glass

May 5, 2019 · Two samples of Antimony containing glass from used solar panels were studied by CPCB for Antimony concentration. The analysis of which indicates that the concentration of

6 FAQs about [Antimony is used in photovoltaic glass]

Does solar glass contain antimony?

However, the composition of solar glass varies, especially concerning antimony (Sb) content, depending on the production method. Antimony is used to enhance the performance of patterned solar glass but introduces environmental and health concerns, complicating recycling efforts.

Is antimony used in Photovoltaic Glass?

The flame-retardant sector currently accounts for around half of end use of antimony.“The use of antimony trioxide as a clarifying agent in photovoltaic glass is a developing trend, and it is expected to maintain rapid growth in the coming years,” Kang said.

Why is antimony used in glass?

Antimony (Sb) is used in the glass to improve stability of the solar performance of the glass upon exposure to ultraviolet (UV) radiation and/or sunlight. However, glass constitutes 5 % only of the end uses of antimony; most of it is used in flame retardants and lead-acid batteries.

Can Borosil remove antimony from solar glass?

Borosil has been able to successfully remove the Antimony from Solar glass. Institut fur Solartechnik SPF, SWITZERLAND, widely considered a GOLD STANDARD for testing and certification of solar glass publishes on its website, test results of solar glass from some of the top solar glass manufacturers in the world.

Can antimony containing solar panels be disposed of?

aic panels and the possible environmental risks or consequences at the end of life of such solar panels. Central Pollution Control Board ( CPCB) has filed a report on ‘Release of Antimony from Solar Panels and the options for disposal of Antimony containing solar panels’ prepared by NGT constituted Expert Members comprising of Professor

Should PV module manufacturers be required to disclose antimony compounds?

To address these challenges, the ESIA Recommendation paper suggests that the European Union should consider mandating PV module manufacturers under the upcoming Ecodesign regulations to disclose the composition and manufacturing process of solar glass, including additives like antimony compounds.

Learn More

- Can photovoltaic power generation be used as glass

- Is photovoltaic glass used

- Huawei Niamey Photovoltaic Glass

- Photovoltaic floor-to-ceiling glass

- Installation of photovoltaic curtain wall with power generation glass

- Photovoltaic Glass A

- Tempered photovoltaic glass

- Photovoltaic glass back frame

- Italian Photovoltaic Glass Industrial Park

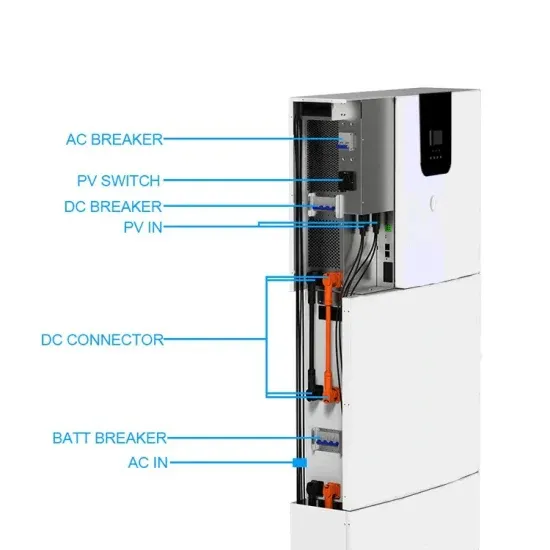

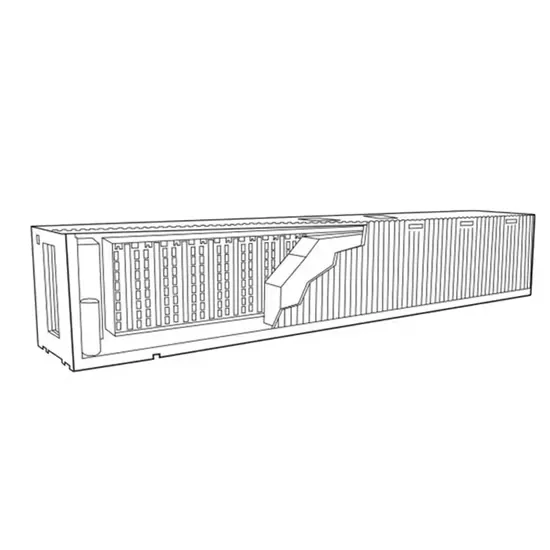

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.