Introduction to deep processing of photovoltaic glass_Sinoy

The deep processing process of photovoltaic glass includes two steps: tempering and coating. Tempering aims to enhance the strength of the glass, while coating is to coat a layer of anti

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating solar cells, and has related

how to make photovoltaic glass › › Basengreen Energy

How is photovoltaic glass made? Photovoltaic glass is made using a process called "solar cell integration". This involves embedding photovoltaic cells into the glass during the

An overall introduction to photovoltaic glass –

Jan 24, 2024 · Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has the important value of protecting cells and transmitting

Exploring the Future: Innovations in Glass

Jul 18, 2024 · Solar panels, called photovoltaic (PV) modules, are designed to convert sunlight into electricity. Glass is one of the most critical components of

PHOTOVOLTAIC GLAZING IN BUILDINGS

Jul 15, 2022 · PV glazing is an innovative technology which apart from electricity production can reduce energy consumption in terms of cooling, heating and artificial lighting. It uses

Solar Panel Manufacturing : Process, Production

Mar 13, 2024 · Solar panel production involves several stages, including silicon processing, wafering, cell fabrication, module assembly, and testing. The

Review of issues and opportunities for glass supply for photovoltaic

Low-iron sand is required for PV glass production, to make the glass highly transparent and reduce the absorption of solar energy. Additionally, glass manufacturing leads to significant

Solar Glass Manufacturers in India | Solar Panel

Feb 23, 2025 · Elevate your solar panels with our anti-reflective coated solar glass. Connect with leading solar glass manufacturers in India for detailed

Glass processing opportunities for solar industry

Dec 7, 2009 · This generally means that processes need to be geared for optimum runs, full utilization of line width and minimum spacing of glass. The special case of solar products

Solar Photovoltaic Glass Production Process

The production of photovoltaic glass involves several stages, from the preparation of raw materials to the final assembly of the glass panels. The first step in the production of

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.7 Summary The factors determining the performance of crystalline silicon solar photovoltaic cells are various factors related to the conversion efficiency of light energy. The

6 FAQs about [What is required for photovoltaic glass processing]

How is Photovoltaic Glass made?

It is made by using a special embossing roller to press a special pyramid pattern on the surface of the ultra-white glass, as shown in Figure 1. At present, there are mainly the following two production processes for photovoltaic glass. (1) The production process of Gridfa glass was invented in 1961 by the Belgian Gravibel Manufacturing Company.

What raw materials are used in Photovoltaic Glass production?

The raw materials used in the production of photovoltaic glass raw materials include soda ash, quartz sand, feldspar, dolomite, limestone, mirabilite, etc. Quartz sand and soda ash are not only the main components in material input, but also the two types of raw materials that have a significant impact on material costs.

What is Photovoltaic Glass?

At present, the mainstream product of photovoltaic glass is low-iron tempered patterned glass (also known as tempered suede glass) with a thickness of 3.2mm or 4mm.

What is the classification of Photovoltaic Glass?

The classification of photovoltaic glass mainly includes ultra white photovoltaic embossed glass, ultra white processed Float glass, TCO glass and backplane glass. The main characteristics are analyzed as follows: (1) Ultra White Photovoltaic Embossed Glass

Which glass is used in photovoltaic power generation?

The glass used in photovoltaic power generation is not ordinary glass, but TCO conductive glass. HHG is a professional glass manufacturer and glass solution provider include range of tempered glass, laminated glass, textured glass and etched glass.

What is glass deep processing?

In order to control costs, glass deep processing often uses both glass tempering and film heat treatment simultaneously. In the production process of photovoltaic glass, the cellar furnace is the core production equipment and also a large investment equipment.

Learn More

- What kind of glass does the photovoltaic glass factory produce

- What is the size of the photovoltaic glass in Conakry

- Slovenia photovoltaic glass greenhouse processing

- Reykjavik glass wholesale processing photovoltaic roof BESS

- What kind of broken glass does the photovoltaic glass factory use

- Photovoltaic glass greenhouse processing plant

- What is the market share of Seoul photovoltaic glass

- Madagascar photovoltaic glass greenhouse processing

- Flat glass processing photovoltaic glass

Industrial & Commercial Energy Storage Market Growth

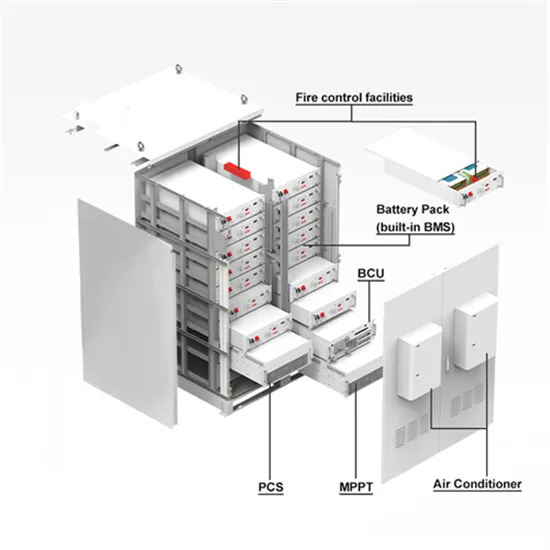

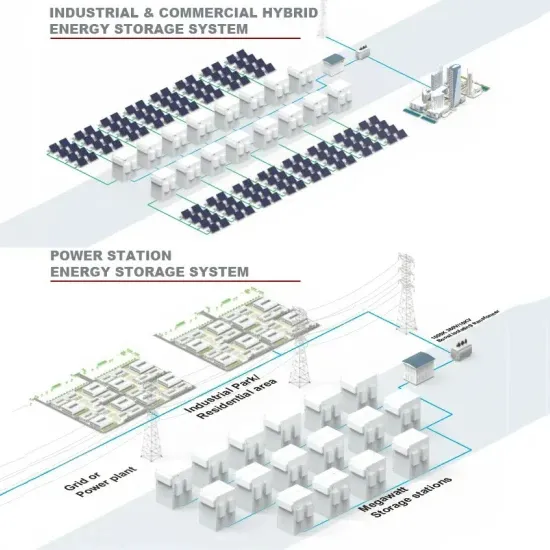

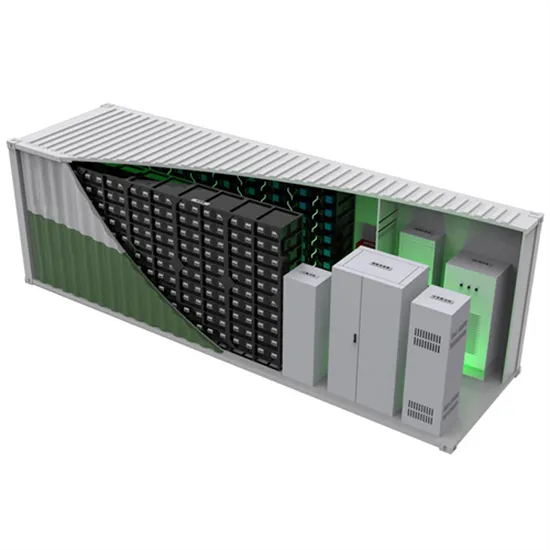

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.