High-efficiency polycrystalline solar cells via COC-SiO2 anti

Jan 1, 2025 · This research focuses on the development of cyclic olefin copolymer (COC) coversheets for polycrystalline photovoltaic cells to minimize the reflection loss. Additionally,

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · This article aims to provide a comprehensive review of the advancements in silicon recovery research and development within the photovoltaic industry over the last decade. It

High-voltage pulse crushing and physical separation of polycrystalline

Aug 15, 2018 · A silicon photovoltaic panel is composed of frames, a junction box, glass, encapsulant, a back sheet, and a photovoltaic cell, which consists of a Si substrate and Cu,

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Single crystalline silicon (also known as monocrystalline silicon) and multi-crystalline silicon (also known as polycrystalline silicon) are two

Demystifying Polycrystalline Solar Panels: How They Operate

Oct 11, 2024 · Polycrystalline solar panels, also known as multi-crystalline solar panels, are a type of photovoltaic technology used to convert sunlight into electricity. The reason why these

Comprehensive investigation of rooftop photovoltaic power

May 3, 2025 · In this study, a comprehensive 3E analysis of an existing rooftop PV power plant combining monocrystalline and polycrystalline silicone PV cell technologies has been carried out.

Huawei-SpecialEdition2020

Jun 10, 2020 · "We hope that all industries can work together to drive innovation across the entire industry chain and ecosystem, optimizing the size and eficiency of PV modules, and using

Huawei polycrystalline photovoltaic panel manufacturer

Photovoltaic panels comprise monocrystalline, polycrystalline or amorphous silicon cells. The cells of polycrystalline panels are made from sections cut from a silicon bar. The silicon crystals are

Performance of Polycrystalline Silicon Material Derived PV

Feb 17, 2025 · The paper presents operating performance of polycrystalline silicon based solar PV modules under variable temperature and irradiance conditions. Annual energy generation

High-efficiency polycrystalline solar cells via COC-SiO2 anti

Jan 1, 2025 · The photovoltaic cells are classified into three generations based on the materials employed and the period of their development. The monocrystalline and polycrystalline silicon

The Sun''s Gift: Exploring the World of Photovoltaic Cells | HUAWEI

May 27, 2024 · Below are some of the common types of photovoltaic cells in the market: 1. Monocrystalline Silicon Cells. Known for their high efficiency and longevity, these cells consist

Life Cycle Analysis (LCA) of photovoltaic panels: A review

Oct 1, 2014 · The environmental impact of photovoltaic panels (PVs) is an extensively studied topic, generally assessed using the Life Cycle Analysis (LCA) methodology. Due to this large

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · In this Review, we survey the key changes related to materials and industrial processing of silicon PV components. At the wafer level, a strong reduction in polysilicon cost

Huawei polycrystalline photovoltaic panel manufacturer

Photovoltaic panels comprise monocrystalline, polycrystalline or amorphous silicon cells. The cells of polycrystalline panels are made from sections cut from a silicon bar.

Modeling and Simulation of Polycrystalline Silicon Photovoltaic

Dec 11, 2019 · The smart grid system can be integrated from different sources of renewable energy, such as photovoltaic panels, built by a large number of solar cells. The aim

Comparison Between Monocrystalline Silicon Photovoltaic Panels

In the rapidly evolving solar photovoltaic (PV) industry, monocrystalline and polycrystalline silicon solar panels stand out as the two main product types, each showcasing unique strengths and

Polycrystalline Silicon

Jul 14, 2024 · Polycrystalline silicon, commonly known as polysilicon, is a high-purity form of silicon crucial to the photovoltaic (PV) industry. It is a fundamental material used to

Polycrystalline silicon solar cells

Jan 1, 2021 · The silicon demand for photovoltaic applications will be increased. The relations among the manufacturers of polycrystalline silicon with demand in the market from 2003 to

Socio-Economic and Environmental Impacts of Silicon Based Photovoltaic

Jan 1, 2013 · Recycling of PV panel is currently not economically viable because waste volumes generated are too small; significant volumes of end-of-life photovoltaic panels will begin to

Why Silicon is the Most Widely Used Material in

May 15, 2024 · Discover why silicon is used in solar panels as the key material for harvesting clean energy efficiently. Explore its vital role in solar technology.

Polycrystalline solar panels: the expert guide [2025]

Jul 14, 2025 · What are polycrystalline solar panels? Polycrystalline solar panels are the result of melted polysilicon being poured into moulds, which are cut

How to Select the Best Polycrystalline Photovoltaic Panels

Choose poly panels with ≤0.15mm silicon cutting loss and oxygen-carbon ratio <1.0. Verify 17.5-19.2% STC efficiency using IV testers showing <2% deviation. Select 1.6mm anodized frames

Experimental comparison between Monocrystalline, Polycrystalline

May 11, 2022 · PV cells are made from semiconductors that convert sunlight to electrical power directly, these cells are categorized into three groups depend on the material used in the

6 FAQs about [Huawei Ottawa polycrystalline silicon photovoltaic panels]

What makes Huawei a successful solar PV company?

Huawei’s success in the global solar PV industry is based on the company’s continuous technological innovation. Most sig-nificantly, it has managed to integrate its powerful information and communications technology (ICT) with its PV products – to create smart PV solutions for lower LCOE and O&M costs.

How efficient are p-type crystalline silicon solar cells with hole-selective passivating contacts?

Yan, D., Cuevas, A., Phang, S. P., Wan, Y. & Macdonald, D. 23% efficient p-type crystalline silicon solar cells with hole-selective passivating contacts based on physical vapor deposition of doped silicon films. Appl. Phys. Lett. 113, 61603 (2018).

How has Huawei influenced large-scale PV development?

Huawei has ushered in a new era for large-scale PV development, with string inverters now selected as a mainstream option in utility-scale projects, which were previously dominated by central inverters. Large-scale PV has also evolved in another way: Bifacial modules coupled with tracking systems are increasingly part of the sys-tem design.

What are crystalline silicon solar cells?

Crystalline silicon solar cells are today’s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This Review discusses the recent evolution of this technology, the present status of research and industrial development, and the near-future perspectives.

Where is Huawei's smart solar PV plant located?

This 49 MW smart solar PV plant – located in Ipoh, Malaysia – is equipped with Huawei’s Smart I-V technology and inverters. everything,” says Yan. This will lead to digital and intelligent upgrades and restructuring across various industries.

What is the efficiency of commercial crystalline silicon photovoltaic cells?

The commercial crystalline silicon photovoltaic cells exhibit an efficiency ranging from 12 % to 19 % .

Learn More

- Installation of monocrystalline silicon and polycrystalline silicon photovoltaic panels

- Flexible monocrystalline silicon solar photovoltaic panels

- Huawei makes solar photovoltaic panels

- Huawei Southern Europe rooftop photovoltaic panels

- Efficiency of monocrystalline and polycrystalline photovoltaic panels

- Huawei Southeast Asia Photovoltaic Panels

- Photovoltaic solar panels vs silicon

- Which photovoltaic panels should I choose polycrystalline or monocrystalline

- Huawei undertakes photovoltaic panels in Tampere Finland

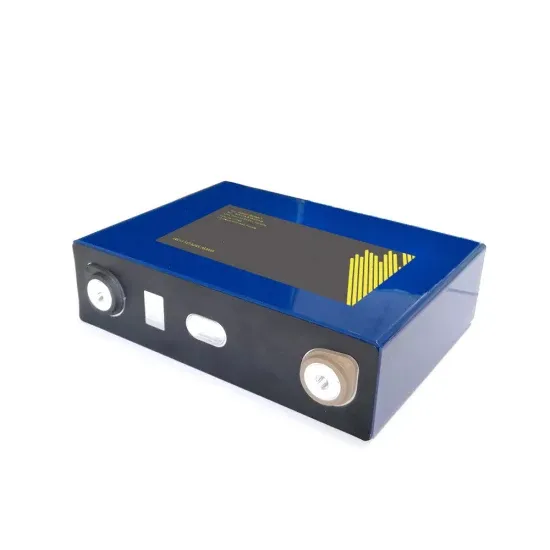

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.