Techno-economic performance comparison of crystalline and thin film PV

Oct 1, 2020 · This investigation compares the financial performance of three different photovoltaic (PV) panel technologies, namely, monocrystalline, polycrystalline and thin film copper indium

Monocrystalline vs. Polycrystalline solar panels

Aug 12, 2024 · Installation of monocrystalline solar panels or polycrystalline solar panels is an important factor affecting the installation of solar photovoltaic power generation system upfront

Types of solar panels: monocrystalline, polycrystalline, and

Dec 17, 2024 · The two dominant semiconductor materials used in photovoltaics are monocrystalline silicon—a uniform crystal structure—and large-grained

How to install monocrystalline silicon photovoltaic panels

Jan 21, 2022 · ations of monocrystalline solar panels: PERC and Bifacial. PERC (Passivated Emitter and Rear Cell): PERC monocrystalline solar panels are designed to increase the

Monocrystalline vs Polycrystalline Solar Panels:

Sep 13, 2024 · Compare monocrystalline and polycrystalline solar panels. Learn about efficiency, cost, and which type is best suited for your solar power needs.

Monocrystalline vs Polycrystalline Solar Panels:

Apr 6, 2025 · As the global shift toward renewable energy accelerates, the choice between monocrystalline and polycrystalline solar panels emerges as a critical

Monocrystalline vs. Polycrystalline vs. Thin-Film

Mar 7, 2025 · When it comes to Monocrystalline vs. Polycrystalline vs. Thin-Film Solar Panels, understanding their distinct characteristics and benefits is

Monocrystalline vs. Polycrystalline Solar Panels

Jan 31, 2025 · Whether you opt for monocrystalline silicon solar panels or polycrystalline PV panels, both options contribute to sustainable energy generation. Before purchasing a solar

Difference: Monocrystalline vs. Polycrystalline Solar Panels

Feb 11, 2025 · Discover the difference between a monocrystalline solar panel and a polycrystalline solar panel. This guide compares efficiency, cost, appearance, performance,

Polycrystalline Solar Panel: Features, Working Principle,

Sep 19, 2024 · polycrystalline solar panel manufacturers melt multiple silicon fragments together to produce the wafers for these panels, the electrons in each cell will have less space to move.

Performance analysis of mono crystalline, poly crystalline and

Dec 1, 2021 · Simultaneously, installation costs vary by device and project. PV materials fall into three categories: crystallized silicon, thin film technology, and new emerging technologies as

Comparing Monocrystalline vs Polycrystalline

May 1, 2025 · This is to say Monocrystalline solar panels feature black-coloured cells made from a single silicon crystal, offering higher efficiency. On the other

Monocrystalline vs Polycrystalline Solar Cells and How to

Mar 12, 2025 · Monocrystalline and polycrystalline silicon solar panels With the rapid development of solar photovoltaic energy storage, its solar panel technology update iteration is also very

Monocrystalline Solar Panels: 2025 Costs & How

Jun 16, 2025 · Monocrystalline solar panels are the top choice for homeowners looking for high efficiency and long-term value. Made from a single crystal of

Performance comparison of mono and polycrystalline silicon

Feb 19, 2022 · The experimental results show that the PRs were 73%, 81% and 91% for amorphous silicon, polycrystalline and monocrystalline panels, respectively [13]. In view of

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Here''s a detailed comparison of Polycrystalline, Monocrystalline, and Thin-Film Solar Panels to help you decide which one is best for your needs:

Comparative Analysis of the Performance of

Feb 17, 2022 · Solar Power Plants (SPS) have an important role as a source of renewable energy to overcome the energy crisis [4]. SPS has the advantages of low production costs and high

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Monocrystalline vs Polycrystalline Solar Panels:

Apr 6, 2025 · Monocrystalline and polycrystalline solar panels exhibit distinct physical characteristics that influence their installation requirements and

Evaluation of the Performance of Polycrystalline

Oct 13, 2023 · In arid regions, the behavior of solar panels changes significantly compared to the datasheets provided by the manufacturer. Therefore, the

Performance evaluation of monocrystalline and polycrystalline

Jan 24, 2023 · PV installation for the plant For the installation of the plant two types of solar panels are selected. One is monocrystalline and the other is a polycrystalline solar panel. It

Monocrystalline Solar Panel — Everything You

Feb 27, 2021 · Our article shows that monocrystalline solar panels are made of high-purity, perfectly oriented silicon crystals, whereas polycrystalline panels

Monocrystalline VS Polycrystalline Solar PV Modules

Jun 20, 2024 · However, the most crucial decision to make for acquiring a system is to identify whether to install monocrystalline or polycrystalline solar panels. In this post, we will list the

6 FAQs about [Installation of monocrystalline silicon and polycrystalline silicon photovoltaic panels]

What are monocrystalline solar panels?

Monocrystalline Monocrystalline solar panels are the most popular solar panels used in rooftop solar panel installations today. Monocrystalline silicon solar cells are manufactured using something called the Czochralski method, in which a ‘seed’ crystal of silicon is placed into a molten vat of pure silicon at a high temperature.

Are polycrystalline solar panels better than monocrystalline solar?

All of the best solar panels currently on the market use monocrystalline solar cells because they are highly efficient and have a sleek design, but come at a higher price point than other solar panels. Polycrystalline solar panels are cheaper than monocrystalline panels, however, they are less efficient and aren’t as aesthetically pleasing.

What are polycrystalline solar panels?

Polycrystalline panels, sometimes referred to as ‘multicrystalline panels’, are popular among homeowners looking to install solar panels on a budget. Similar to monocrystalline panels, polycrystalline panels are made of silicon solar cells. However, the cooling process is different, which causes multiple crystals to form, as opposed to one.

How are monocrystalline solar cells made?

Monocrystalline silicon solar cells are manufactured using something called the Czochralski method, in which a ‘seed’ crystal of silicon is placed into a molten vat of pure silicon at a high temperature. This process forms a single silicon crystal, called an ingot, that is sliced into thin silicon wafers which are then used in the solar modules.

What is a monocrystalline PV module?

(a) Classification of PV materials (b) Monocrystalline PV Module (c) Polycrystalline PV Module (d) Thin-film PV Module. Monocrystalline is created by slicing cells from a single cylindrical silicon crystal. Monocrystalline silicon needs a more complex manufacturing process than other technologies, resulting in slightly higher costs .

Are polycrystalline solar panels the cheapest option?

Historically, polycrystalline panels have been the cheapest option for homeowners going solar, without majorly sacrificing panel performance. Low prices allowed polycrystalline panels to make up a significant market share in residential solar installations between 2012 and 2016.

Learn More

- Are monocrystalline silicon photovoltaic panels afraid of corrosion

- Monocrystalline silicon high power photovoltaic panels

- Monocrystalline silicon photovoltaic panels solar energy

- Making monocrystalline silicon photovoltaic panels

- Efficiency of monocrystalline and polycrystalline photovoltaic panels

- Which photovoltaic panels should I choose polycrystalline or monocrystalline

- Price difference between monocrystalline and polycrystalline photovoltaic panels

- Huawei Ottawa polycrystalline silicon photovoltaic panels

- Flexible monocrystalline silicon photovoltaic panels

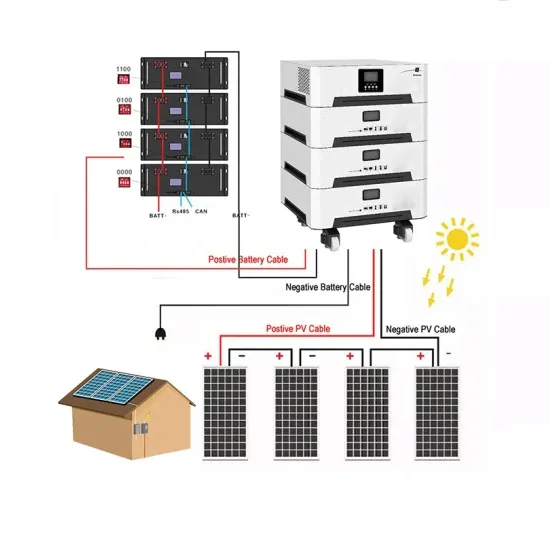

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.