UPS System Inspection and Battery Maintenance –

Jul 28, 2025 · Battery Discharge Testing: Conduct regular battery discharge tests to verify actual runtime capacity rather than relying solely on voltage readings. This provides a more accurate

BATTERY CABINETS-Battery Cabinet-KEBOS POWER CO., LTD.-

Battery cabinets for all KEBOS UPS from 1KVA up to 1200KVA Power Range.The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 17AH to 250AH.The

UPS Electrical Function Test and Field Inspection.

Battery Tests: Voltage Test: Measure the voltage of the battery or battery strings to ensure they are within the manufacturer''s recommended range. Load Test: This involves applying a load to

What Should The Voltage Of A UPS Battery Be

Dec 13, 2023 · Common UPS battery voltages include 12V, 24V, 48V, and higher. The selection of the appropriate voltage for a UPS system depends on the specific application, power

Data Analysis to Optimize UPS Battery Performance and

Jan 10, 2023 · Failure of a data center''s uninterruptible power supply (UPS) system can mean substantial losses for most businesses, and batteries are consistently a leading root cause of

UPS System Inspection and Battery Maintenance –

Jul 28, 2025 · Comprehensive procedure guide for UPS system inspection and battery maintenance. Ensure reliability and prevent failures in critical power backup systems.

Eaton 9355 (20/30 kVA) UPS battery upgrade instructions

Sep 9, 2024 · The total battery string voltage in a 9355 20-30 kVA UPS is 216V (18 batteries, where is each battery is 12V nominal). Two strings fit in each battery shelf of the 9355 20-30

UPS Battery Room Maintenance and Precautions

Apr 10, 2025 · Float Voltage: Each cell in the ups battery system should maintain a float voltage between 13.5V and 13.8V. Voltage Imbalance: If the voltage difference within a battery series

Test,use and maintenance of battery for UPS

Mar 30, 2024 · Test,use and maintenance of battery for UPS uninterruptible power supplyThe so-called termination voltage refers to the voltage at which the battery cannot work normally when

How To Check Ups Battery Voltage With Multimeter?

Jun 23, 2025 · We then provided a step-by-step guide to checking the battery voltage with a multimeter, including setting the multimeter to DC voltage mode, connecting the probes to the

How to Test a UPS Battery with a Multimeter: A

2 days ago · Identify Your Battery''s Voltage: First, determine the nominal voltage of your UPS battery. Most single-phase UPS systems use a 12V battery, but

UPS Battery Sizing

Apr 8, 2012 · Example of UPS battery sizing Select the battery model number and quantity (using the typical watts per cell table) for a 300 kVA UPS, 94% efficiency, power factor of 0.8, for a

ZincFive BC Series UPS Battery Cabinets

Jun 9, 2023 · ZincFive BC Series UPS Battery Cabinet Introduction The ZincFive BC Series UPS Battery Cabinet is comprised of ZincFive''s Nickel-Zinc Batteries integrated into a battery

Different Types Of UPS Batteries

The advantages of Li-Ion include higher reliability than traditional VRLA/SLA batteries because of built-in battery monitoring and management systems, which check every individual cell for any

Cabinet UPS Maintenance Checklist

May 21, 2024 · Check & measure of voltage reading of both input and output Check & measure of current reading of both input and output Inspection of loads normal distribution per phase Off

Eaton-Battery-Handbook-BAT11LTA.PDF

Apr 20, 2018 · There are primarily three kinds of batteries used in UPSs—valve-regulated lead-acid (VRLA), also known as sealed or maintenance-free lithium-ion batteries, and vented lead

How to Test a UPS Battery with a Multimeter: A

2 days ago · It can measure voltage, current, and resistance, essential metrics for testing a UPS battery''s health. Why Test Your UPS Battery? Testing your

Eaton UPS fundamentals handbook

Jul 2, 2025 · Handbook. From plug and receptacle charts and facts about power problems to an overview of various UPS topologies and factors affecting battery life, you''ll find a wealth of

UPSB505 Uninterruptible Power Supply UPS Battery

High voltage levels are present within the UPS. The UPS should be opened only by service personnel that are qualified. The UPS must have a proper ground connection to earth.

6 FAQs about [UPS battery cabinet voltage check]

How do you test a UPS battery?

General UPS Electrical Testing. Voltage Test: Measure the voltage of the battery or battery strings to ensure they are within the manufacturer’s recommended range. Load Test: This involves applying a load to the battery to simulate real operating conditions. It helps in assessing the battery’s ability to hold a charge and deliver power when needed.

How do I check the voltage on my ups?

Power Off: Before conducting any voltage check, make sure to turn off and disconnect any devices connected to the UPS system. This ensures your safety and prevents any electrical interference during the testing process. Access the Battery: Depending on the UPS model, you may need to open the battery compartment or access panel to reach the battery.

How do I know if my ups battery is compatible?

Compatibility: Check the compatibility of the UPS system and the UPS battery voltage. Ensure that both the UPS unit and the battery are designed to work together effectively. Using an incompatible battery voltage can negatively impact the UPS system’s performance and even lead to damage.

What voltage do ups need?

Different types of UPS systems have varying voltage requirements. Common UPS battery voltages include 12V, 24V, 48V, and higher. The selection of the appropriate voltage for a UPS system depends on the specific application, power requirements, and the devices being powered.

What voltage is a UPS battery?

The most common voltage ratings for UPS batteries include: 12V: This is a popular voltage rating for small-scale UPS systems and is commonly used to power individual devices such as routers, modems, and small electronics.

What determines the voltage rating of a UPS battery?

It’s important to note that the actual number of cells within the UPS battery determines the voltage rating. Each cell typically has a nominal voltage, and when multiple cells are connected in series, their voltages add up to create the overall battery voltage rating.

Learn More

- UPS battery cabinet has voltage to ground

- Can I open the battery cabinet after the UPS is turned off

- UPS battery cabinet battery quantity

- Check the quality of the battery cabinet

- Battery cabinet voltage regulator module

- How to connect 32 batteries in a UPS battery cabinet

- How to measure the total voltage in the battery cabinet

- UPS battery cabinet processing manufacturer

- Emergency UPS battery cabinet

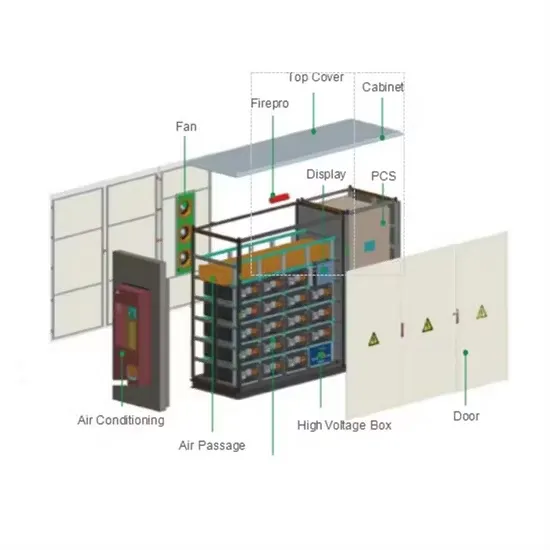

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.