BATTERY CABINETS-Battery Cabinet-KEBOS POWER CO., LTD.-

Battery cabinets for all KEBOS UPS from 1KVA up to 1200KVA Power Range.The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 17AH to 250AH.The

Eaton s lithium-ion UPS battery Q&A

Mar 21, 2025 · This document will serve as a guide for Eaton salespersons, sales support personnel, engineering clients, and end users who have questions regarding the lithium

Eaton Top Wiring Kit for Type S Battery Cabinet installation

Mar 31, 2025 · The top wiring kit bolts to the top of the Samsung battery cabinet and provides customer landing terminals for DC power, an AC power terminal block for the battery cabinet

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

Steps for Installing UPS Batteries – Leading Battery-Wuxi

Oct 23, 2024 · Uninterruptible Power Supply (UPS) systems rely on batteries to provide backup power during outages or fluctuations. Installing these batteries correctly is crucial for system

UPS Battery Cabinets | Information by Electrical Professionals

Feb 7, 2024 · The batteries are factory installed in the cabinets and connected by jumpers between the cabinets. Depending on the battery size the cabinets can weigh up to 5000

Different Types Of UPS Batteries

There are three main types of batteries used in uninterruptible power supplies: Nickel-Cadmium, Lead-Acid, and Lithium-Ion. There isn''t a single "best" UPS battery technology – the choice

Eaton internal battery instructions for Eaton 9155 or

Nov 20, 2021 · When purchasing UPS cabinets without batteries, only the following type is recommended. Use of any other battery type inside Eaton cabinets will void the product warranty.

Eaton three-phase UPS battery handbook

Apr 3, 2025 · Battery failure is a leading cause of UPS load loss. Knowing how to properly maintain UPS batteries will help you manage your IT power more efficiently and avoid power

VertivTM Liebert® ITA2 Battery Cabinet

Feb 27, 2020 · Refer to the illustration, "Cabling 3U Cabinets in Parallel," above, and connect the UPS-to-battery cable to Connectors A on each battery cabinet in the battery string.

6 FAQs about [How to connect 32 batteries in a UPS battery cabinet]

What is a proper connection between a battery and an ups?

A proper connection between the battery and the UPS enables efficient power flow from the battery to the connected devices. This connection allows the UPS to seamlessly switch to battery power during blackouts or voltage fluctuations, ensuring uninterrupted operation of critical equipment such as servers, computers, and communication systems.

How do you put a battery in an ups?

Then, locate the battery compartment on the UPS and open it. Insert the battery into the compartment, making sure to connect the positive and negative terminals correctly. Lastly, close the battery compartment and plug the UPS back into the power source. What type of battery is best for a UPS?

Can I connect multiple batteries to my ups?

A: It depends on the specific UPS model and its design. Some UPS models may allow for multiple batteries to be connected in parallel for increased runtime or redundancy. Refer to the manufacturer’s guidelines or consult a professional to determine if your UPS supports multiple battery connections and the correct procedure for doing so.

What type of battery is used for UPS connection?

Lead-acid batteries are one of the most common types used for UPS connection. They are reliable and have a long service life. These batteries are available in two variants – flooded lead-acid (FLA) and valve-regulated lead-acid (VRLA). 1.

Should I use a series connection for my battery and ups?

Consider using series connection for your battery and UPS hookup to optimize the performance of your backup power system. Parallel connection refers to the process of linking multiple batteries together to a single UPS. This configuration offers several benefits for both the battery and the UPS system.

How to extend battery life in a UPS connection?

One of the most crucial aspects of extending battery life in a UPS connection is to ensure that the battery and the UPS are properly connected. This includes checking the polarity of the battery terminals and properly connecting the cables. 2. Use the Right Battery

Learn More

- How to make a UPS battery cabinet

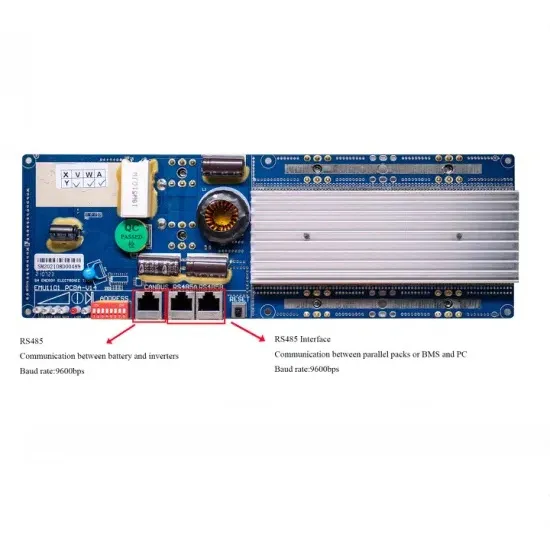

- How to connect the signal base station battery to the power distribution cabinet

- How to choose the main incoming wind power of UPS battery cabinet

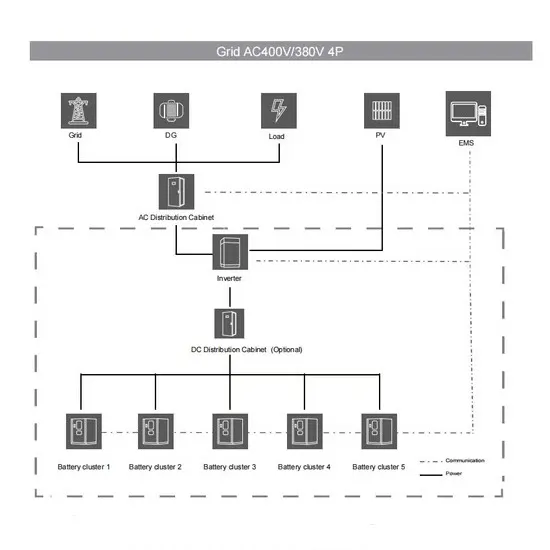

- How to connect the cylindrical energy storage cabinet of the communication base station battery energy storage system

- How to buy battery cabinet replacement batteries

- How to determine the support frame of UPS battery cabinet

- How long is the shelf life of the battery in the energy storage cabinet

- How much is the price of outdoor communication battery cabinet in the Netherlands

- How to calculate power and current in battery cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.