Eaton UPS fundamentals handbook

Jul 2, 2025 · Positive grid corrosion has been the most common end-of-life factor for UPS batteries, which is a result of the normal aging process due to UPS battery chemistry and

Eaton three-phase UPS battery handbook

Apr 3, 2025 · Battery failure is a leading cause of UPS load loss. Knowing how to properly maintain UPS batteries will help you manage your IT power more efficiently and avoid power

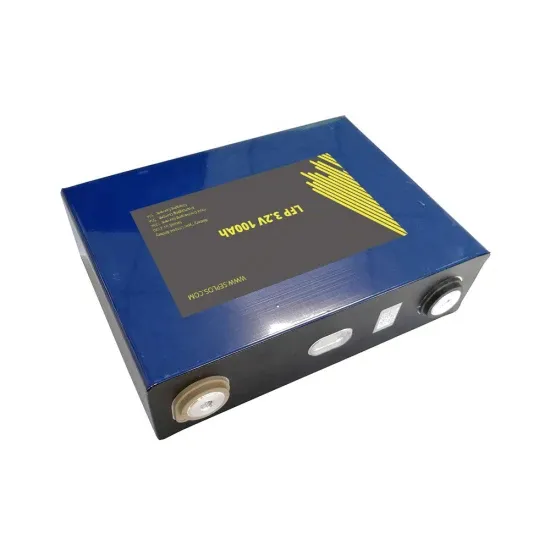

Eaton s lithium-ion UPS battery Q&A

Mar 21, 2025 · This document will serve as a guide for Eaton salespersons, sales support personnel, engineering clients, and end users who have questions regarding the lithium

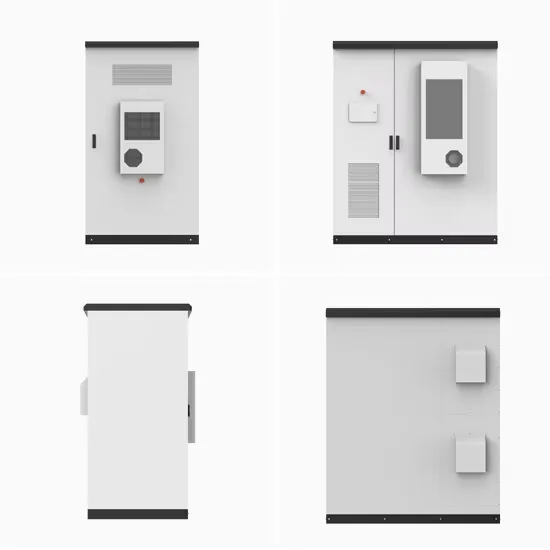

How UPS Battery Cabinet Keep Businesses Powered

Jun 20, 2025 · Discover how UPS battery cabinet protect your business from costly downtime. Learn how they work, why they matter, and how to choose the right one.

The Eaton UPS and Power Management Fundamentals

Jan 9, 2024 · The batteries used in the UPS and associated battery modules and cabinets are sealed, lead acid batteries often referred to as maintenancefree batteries hile this type of

UPS Battery Cabinets

Mar 5, 2025 · Support For technical support, or questions about the safe installation, operation, or maintainence of ZincFive batteries, please contact a ZincFive support representative: Phone:

What Are the Key Considerations for UPS Battery Rack Sizes

Jun 15, 2025 · What Types of UPS Battery Racks Are Available? Common UPS battery rack types include wall-mounted, floor-standing, and modular designs. Wall-mounted racks save space

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

S5KC EBC User Quick-Start Guide May 2015

Feb 26, 2019 · Connecting External Battery Cabinet Up to four external battery cabinets may be connected to the SolaHD S5KC UPS to increase battery run times. The external battery

BC Series UPS Battery Cabinets

Jan 23, 2024 · Safety Symbols ZincFive BC Series UPS Battery Cabinet are carefully designed and manufactured to ensure that they are safe and reliable products when used properly. To

UPS Buying Guide: Battery Back-up for Network Closets | Eaton

Apr 13, 2025 · Selecting the right UPS battery back-up for your network cabinet or IDF can be a confusing process. This uninterruptible power supply (UPS) buying guide is designed to help

Liebert® EXS External Battery Cabinet Installer/User Guide

Jan 31, 2024 · This manual contains important instructions that should be followed during installation of your VertivTM Liebert® EXS Battery Cabinet and accessories. Read this manual

Liebert® EXS External Battery Cabinet Installer/User Guide

Jan 31, 2024 · For battery cabinets that are connecting to a VertivTM Liebert® EXS UPS, see Figure 2.1 on page 8, cables will run from the positive, negative and neutral busbars of the

6 FAQs about [How to determine the support frame of UPS battery cabinet]

How to choose UPS battery cabinets?

Furthermore, the cabinets need to offer removable hinged doors so that the UPS system can be easily accessed. Doors need to be locked for safety and security. UPS Battery Cabinets have to be designed to house most front terminal batteries. Your UPS Battery Cabinets should have removable side panels so that cables can be easily installed.

Where are the cabinets in the UPS system placed?

Each cabinet in the UPS system is placed in its final installation location. The UPS (Uninterruptible Power Supply) and MBC (Main Battery Cabinet) must be installed on a level floor suitable for computer or electronic equipment. The MBC (Main Battery Cabinet) is bolted to the floor for permanent installations. All conduits and cables are properly routed to the MBC.

Should UPS batteries be installed on racks or in cabinets?

Early on in a UPS design a decision must be made on whether batteries should be installed on racks or in cabinets. Both have pros and cons. The following are typical design considerations.

How many batteries can a battery cabinet hold?

4Ah to 105Ah (C10).The battery cabinets are available in 5 different mechanical dimensions, are able to contain various combination of Batteries, up to maximum 63 blocks, connected in series and parallel, with positive, negative and middle point poles and with max D tery Capacit (Ah)St dard IEC-EN 62040-1in the cabinet are included Fuse Hold

How to install a battery rack?

4. In the 32-battery scenario, remove batteries numbered 05, 06, 15, 16, 25, 26, 35, and 36. Step 1 Determine the mounting holes for the battery rack based on the marking-off template. Step 2 Drill holes and install expansion bolts. Step 3 Install side frames. Partially tighten the bolts before installing supports.

How do you install a 40 battery rack?

4. In the 40-battery scenario, remove batteries numbered 38, 37, 36, 35, 14, 13, 12, and 11. Step 1 Determine the mounting holes for the battery rack based on the marking-off template. Step 2 Drill holes and install expansion bolts. Step 3 Install side frames. Step 4 Install supporting brackets in sequence from top down to secure supports.

Learn More

- How to choose the main incoming wind power of UPS battery cabinet

- How to connect 32 batteries in a UPS battery cabinet

- How to make a UPS battery cabinet

- How to increase the current and voltage of the battery cabinet

- UPS battery cabinet production and sales

- How to assemble the battery cabinet in the computer room

- How to replace the battery in photovoltaic energy storage cabinet

- How is the Togo lithium battery energy storage cabinet

- How big is the indoor battery cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.